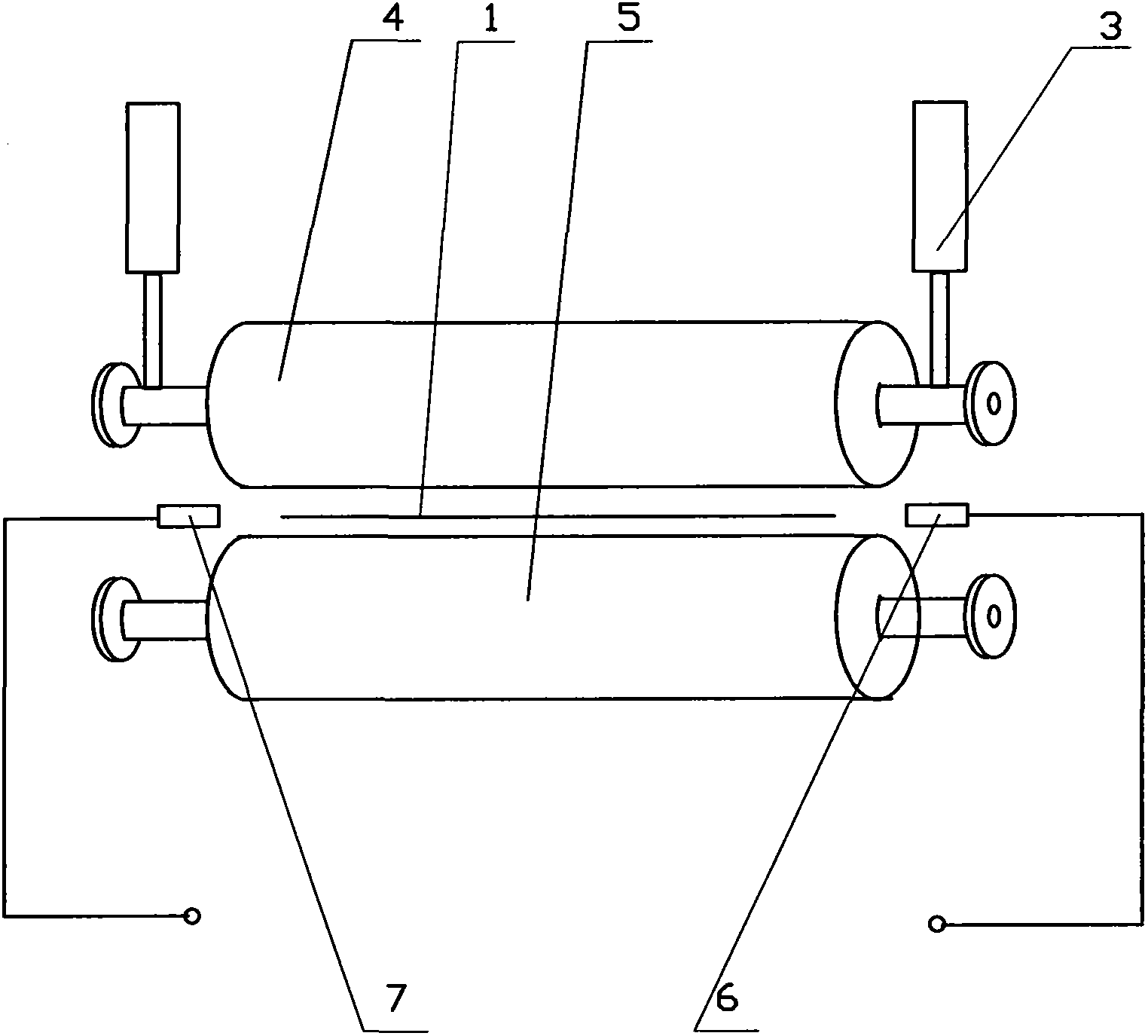

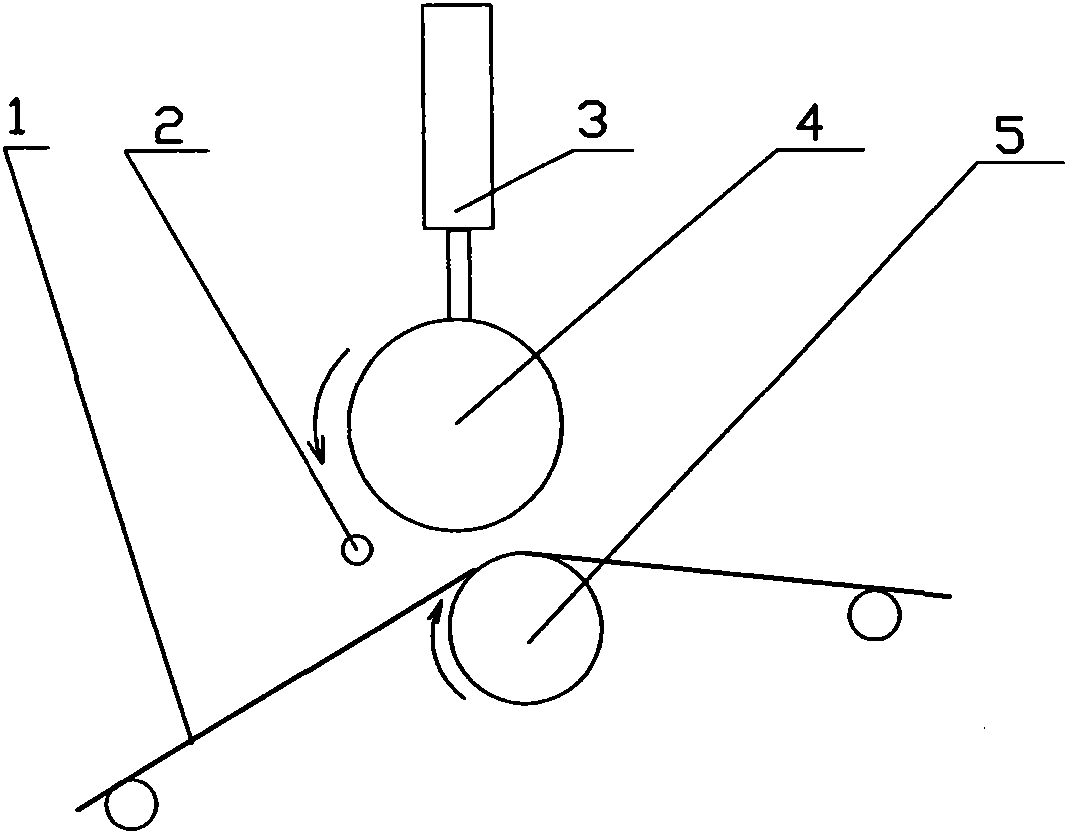

Compression roller safety control device

A technology of safety control and pressure roller, applied in the direction of control of lamination, lamination, chemical instruments and methods, etc., can solve the methods and cases where the relationship between safety and production is not seen, and it is easy to be brought under the pressure roller by the film tape to be pressed Injury, affecting the normal production of the next process, etc., to achieve the effect of automatic safety protection, fast response, and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

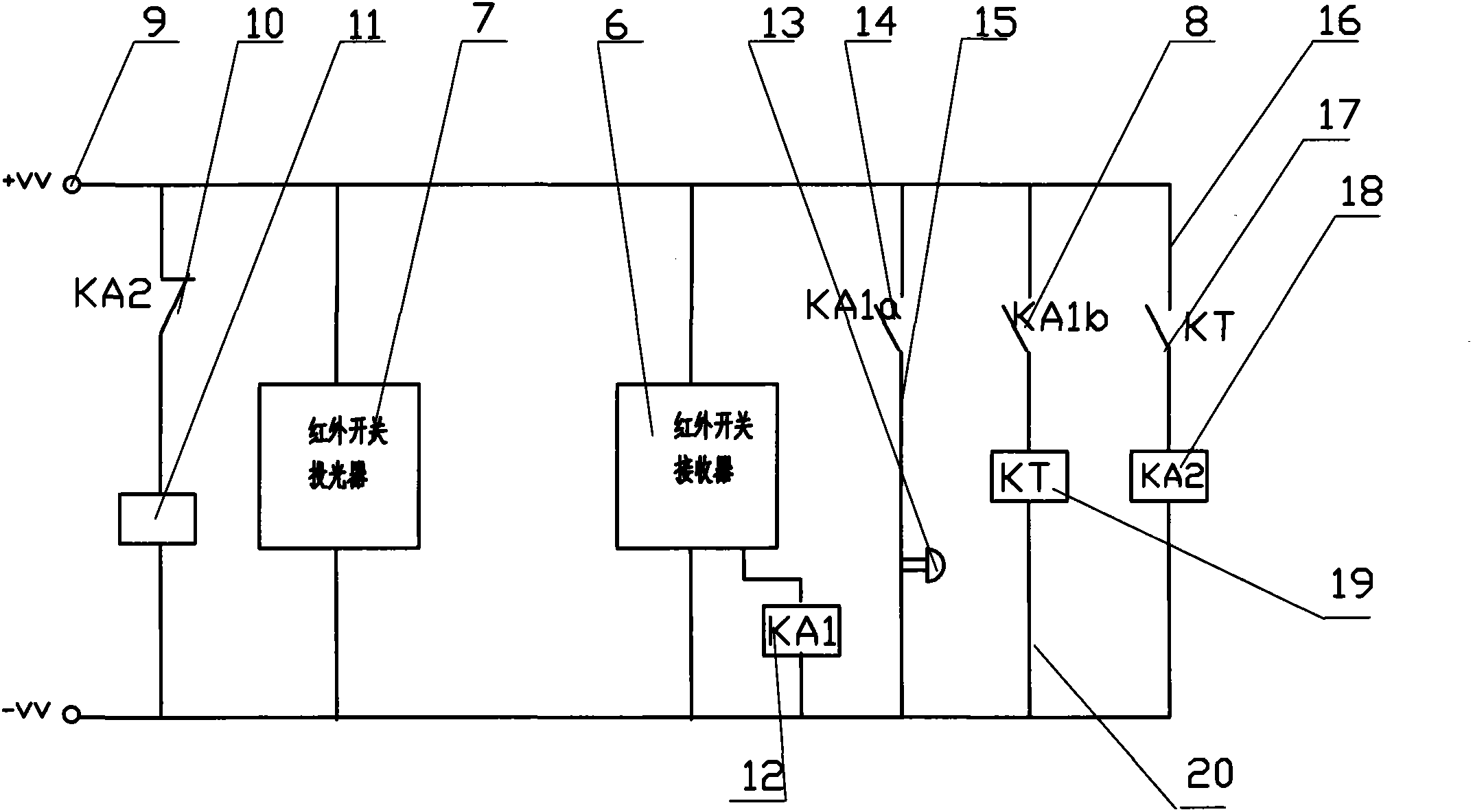

[0015] The present invention will be described in detail below in conjunction with specific embodiment and comparative example:

[0016] The present invention utilizes the infrared photoelectric switch and double protection, taking into account the dual purposes of safety and production. Considering the two directions of safety and production, the embodiments can be combined arbitrarily under the premise of achieving the above purpose, and are not limited to the following specific disclosures Example.

[0017] The molding machine of the prior art does not use an infrared safety protection device, and the action of the original pressure roller is realized by the electromagnetic reversing valve 11 connected in series in the circuit. The existing technology is: when the production starts and the pressure roller 4 needs to be pressed together , the working power supply 9 supplies power, the electromagnetic reversing valve 11 is energized, and the electromagnetic reversing valve 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com