Large-area-friction-induced micron-scale processing equipment in multipoint contact mode

A multi-point contact and friction-induced technology, which is applied in the process of producing decorative surface effects, microstructure technology, microstructure devices, etc., can solve the problems of slow processing speed, limited processing efficiency, low efficiency, etc. The structure is uniform, the processing efficiency is improved, and the processing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

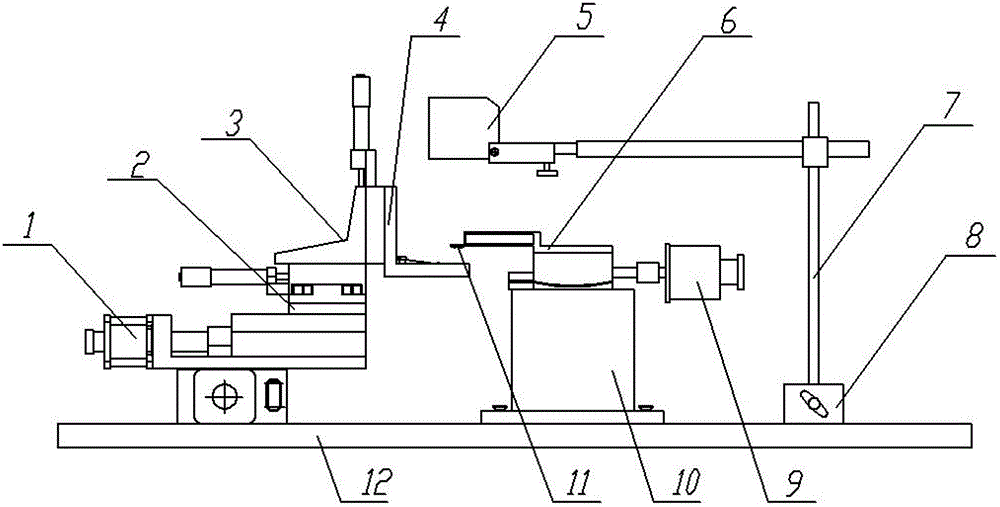

[0036] figure 1 As shown, a specific embodiment of the present invention is a large-area friction-induced micron-scale processing equipment in a multi-point contact mode, which consists of a base 12, a processing platform driving device on the base 12, and a It is composed of loading mechanism and data acquisition and control system, among which:

[0037] The composition of the processing platform driving device is: the horizontal two-dimensional electronically controlled translation platform 1 is fixed on the upper surface of the base 12 by bolts, the bottom plate of the manual three-dimensional displacement platform 3 is fixed on the horizontal two-dimensional electronically controlled translation platform through the connecting plate 2 The upper surface of 1; the vertical plate of the manual three-dimensional translation stage 3 is fixedly connected with the vertical plate of the "L"-shaped sample table 4;

[0038] The composition of described loading mechanism is: electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com