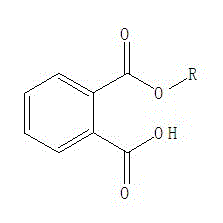

Method for eliminating phthalic monoester-type environmental hormone in water body

A technology based on environmental hormones and phthalic acid alone, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of fast removal rate, easy regeneration and reuse of adsorbents, and large adsorption capacity, and achieve removal Fast efficiency, good regeneration effect, and large saturated adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] After filtering 20 L of monomethyl phthalate wastewater with a concentration of 500 mg / L, adjust the pH to 3 with 0.1 mol / L hydrochloric acid, and add 200 g goethite to it to make the concentration reach 10 g / L. Stir the reaction at 1790rmp / min for 24 hours at 5°C, filter out the goethite after the adsorption reaches equilibrium, add it to 0.7L sodium hydroxide solution with a concentration of 1mol / L, and add it to 500 After stirring and desorbing at the speed of rpm / min for 4 hours, the goethite was filtered out, washed with distilled water until neutral, dried at 50°C for 8 hours, and then recycled and reused. The desorption liquid is recycled as a desorption agent. The concentration of monomethyl phthalate in the treated wastewater was 0.08 mg / L.

Embodiment 2

[0024] After 20L of monoethyl phthalate wastewater with a concentration of 400mg / L was filtered, the pH was adjusted to 3 with 0.1mol / L hydrochloric acid, and 140 g of goethite was added thereto to make its concentration reach 7 g / L. Under the temperature condition of ±5°C, stir the reaction at a speed of 1000rmp / min for 24h. After the adsorption reaches equilibrium, filter out the goethite, add it to 0.5L of sodium hydroxide solution with a concentration of 1mol / L, and set the temperature at 25°C to After stirring and desorbing at a speed of 500 rpm / min for 4 hours, the goethite was filtered out, washed with distilled water until neutral, dried at 50°C for 8 hours, and then recycled and reused. The desorption liquid is recycled as a desorption agent. The concentration of monoethyl phthalate in the treated wastewater was 0.07 mg / L.

Embodiment 3

[0026] After 20L of monobutyl phthalate wastewater with a concentration of 300mg / L was filtered, the pH was adjusted to 4 with 0.1mol / L hydrochloric acid, and 100 g of goethite was added thereto to make its concentration reach 5 g / L. Under the temperature condition of ±5°C, stir the reaction at a speed of 1000 rpm / min for 24 hours. After the adsorption reaches equilibrium, filter out the goethite, add it to 0.4L of sodium hydroxide solution with a concentration of 1mol / L, and store at 40°C After stirring and desorbing at a speed of 300rmp / min for 4h, the goethite was filtered out, washed with distilled water to neutrality, dried at 50°C for 8h, and then recovered and reused. The desorption liquid is recycled as a desorption agent. The concentration of monobutyl phthalate in the treated wastewater was 0.05 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com