High-efficient and environment-friendly treatment process of animal manure

A technology for environmental protection treatment of livestock and poultry manure, applied to the treatment of biological organic parts, the preparation and application of organic fertilizers, etc., can solve the problems of producers restricting the process of agricultural industrialization and unsatisfactory objective effects, and achieve the improvement of fermentation efficiency , high efficiency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

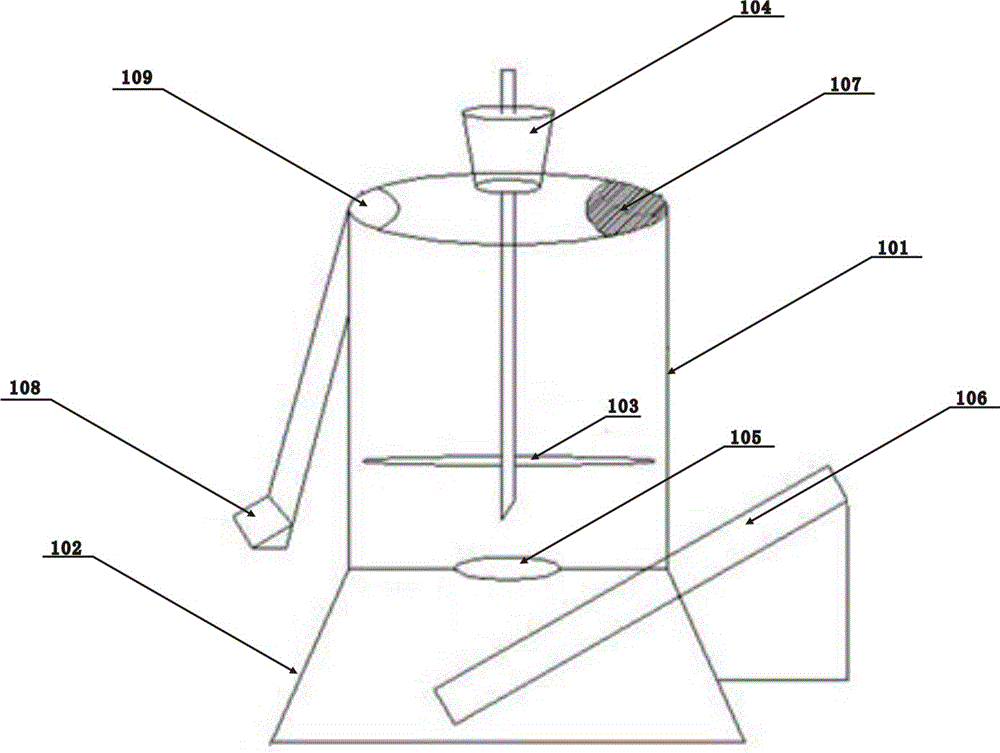

[0032] Embodiment 1: a kind of high-efficiency and environment-friendly treatment process of livestock and poultry manure, is characterized in that: treatment process is

[0033] A. Mix raw pig manure (with a water content of 90%) and fungus residue at a ratio of 6:4;

[0034] B, adding the mixed material into the treatment pot for fermentation;

[0035] C. Heat the treatment pot to 70-90°C for aerobic fermentation for 12-24 hours, kill harmful bacteria and insect eggs at high temperature, and add high-temperature bacteria population at the same time, stir to make the temperature of the content uniform, the bacteria population uniform, and ferment uniform. ,

[0036] D. Cut off the power, rely on the heat energy of fermentation organisms to maintain 70-90 degrees, and leave the tank after 12-24 hours;

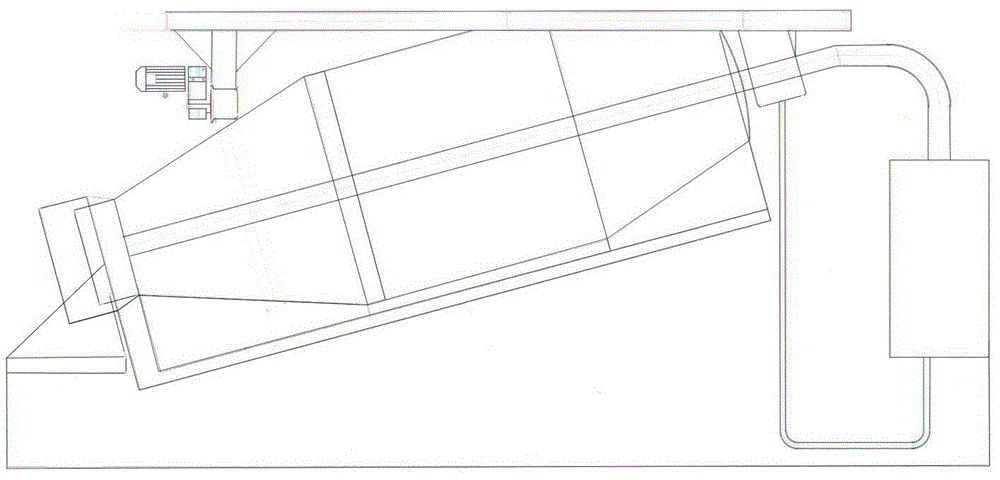

[0037] E. After being out of the pot, it is piled up, and it is aerated under high pressure for secondary fermentation to further lose water. After 12-24 hours of fermentati...

Embodiment 2

[0038] Embodiment 2: a kind of high-efficiency and environment-friendly treatment process of livestock and poultry manure, is characterized in that: treatment process is

[0039] A. Mix raw pig manure (with a water content of 90%) and sawn wood in a ratio of 5-5;

[0040] B, adding the mixed material into the treatment pot for fermentation;

[0041] C. Heat the treatment pot to 70-90°C for aerobic fermentation for 12-24 hours, kill harmful bacteria and insect eggs at high temperature, and add high-temperature bacteria population at the same time, stir to make the temperature of the content uniform, the bacteria population uniform, and ferment uniform.

[0042] D. Cut off the power, rely on the heat energy of fermentation organisms to maintain 70-90 degrees, and leave the tank after 12-24 hours;

[0043] E. After being out of the pot, it is piled up, and it is aerated under high pressure for secondary fermentation to further lose water. After 12-24 hours of fermentation, it c...

Embodiment 3

[0044] Embodiment 3: a kind of high-efficiency and environment-friendly treatment process of livestock and poultry manure, is characterized in that: treatment process is

[0045] A. Mix raw pig manure (with a water content of 90%) and straw in a ratio of 6-4;

[0046] B, adding the mixed material into the treatment pot for fermentation;

[0047] C. Heat the treatment pot to 70-90°C for aerobic fermentation for 12-24 hours, kill harmful bacteria and insect eggs at high temperature, and add high-temperature bacteria population at the same time, stir to make the temperature of the content uniform, the bacteria population uniform, and ferment uniform.

[0048] Bacteria population

[0049] D. Cut off the power, rely on the heat energy of fermentation organisms to maintain 70-90 degrees, and leave the tank after 12-24 hours;

[0050] E. After being out of the pot, it is piled up, and it is aerated under high pressure for secondary fermentation to further lose water. After 12-24 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com