Loading/unloading wing ring, loading/unloading wing ring mechanism, and power generator, water activator and water activating method thereof

A generator and wing ring technology, applied in the field of wind or water wheels, can solve the problems of occupying too much air space, difficult to produce, high aerodynamic technical requirements, etc., and achieve the effect of reducing construction difficulty and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

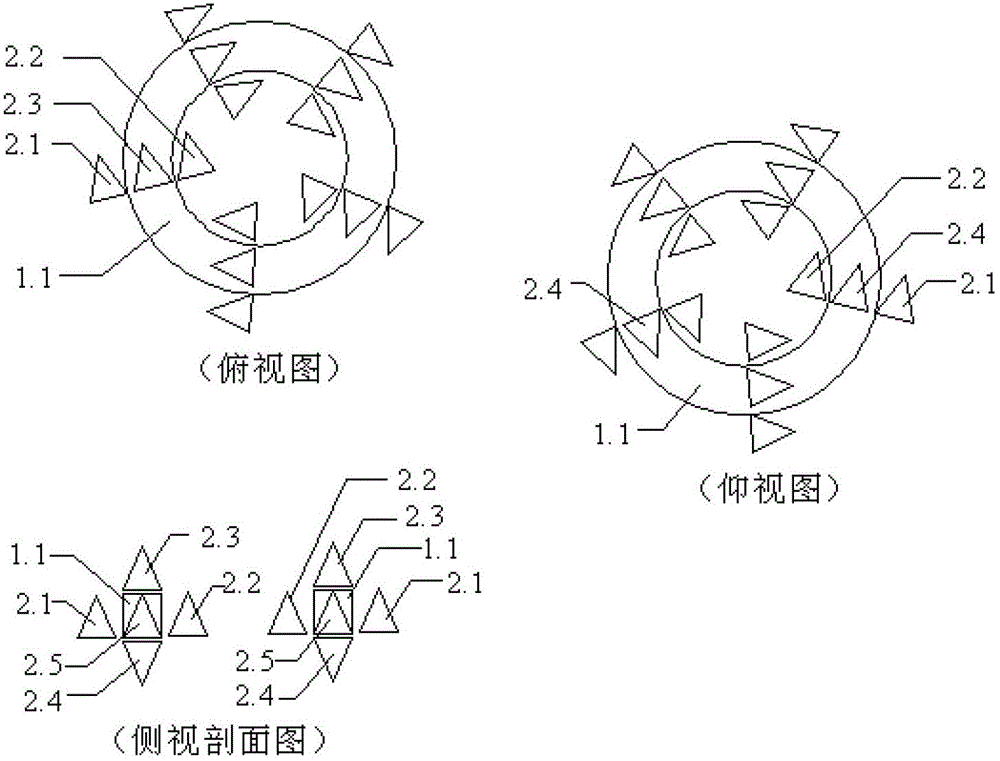

[0183] Example 1 (eg figure 1 ):

[0184]The fins are either inside the ring, or outside the ring, or above the ring, or below the ring, or inside the cavity of the ring support. The fins can be arranged equidistantly on one of the five circles such as the inner, outer, upper, lower, or inside of the cavity, or two, three, or four of the five circles Or five fins are provided at the same time, and the fins respectively arranged on different circumferences can not be connected into pieces, or can be connected into one large fin, thereby forming a semi-enclosed shape for the frame cavity of the ring bracket, or Form an almost full enclosure (just leave a little gap for the bracket of the rail car to pass through, such as Figure 20 , fins in Figure I). Some unloading wing rings for special purposes can even connect the fins at five positions into one piece (such as Figure 9 fins in 2).

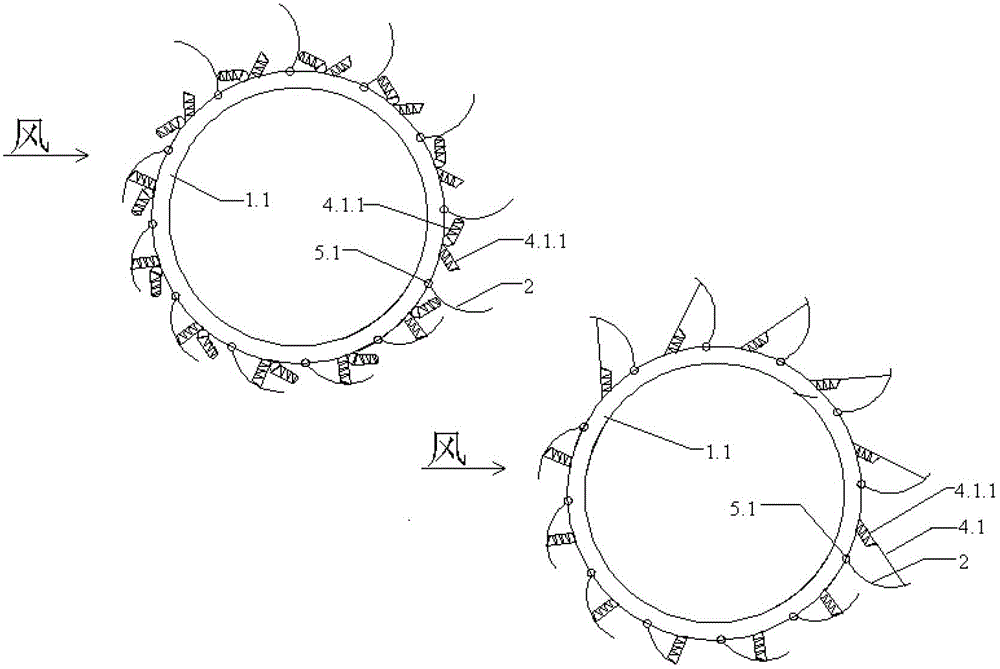

[0185] Example 2 (eg figure 2 , image 3 ):

[0186] Each wing 2 is connected wit...

example 3

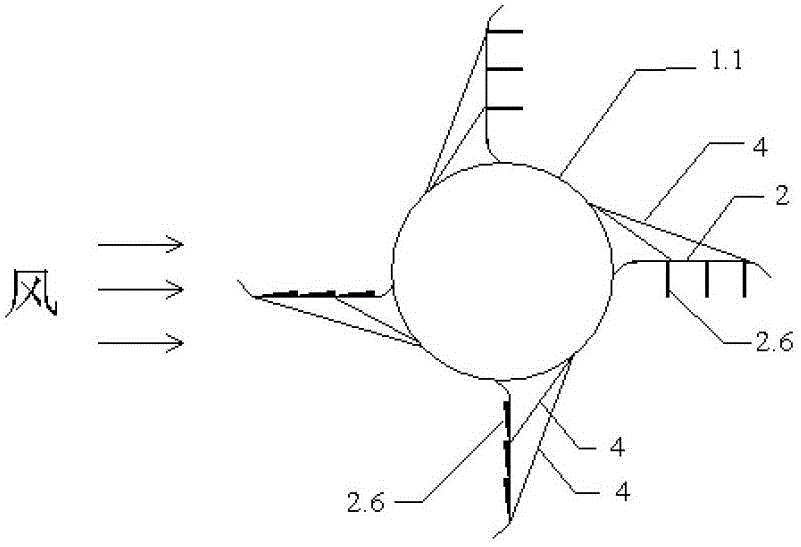

[0189] Example 3 (such as figure 2 ):

[0190] select Figure 4 In the E-shaped fin, the root of the fin is connected to the ring bracket of the wing ring, the upper end of the fin skeleton is connected to one end of the connecting rod 4, the other end of the connecting rod 4 is connected to the ring bracket 1.1, and the connecting rod 4 and the fin skeleton form a triangle. The E-shaped fin has a non-deformable skeleton, and the skeleton can be made of hard material or soft cloth; the corresponding position of the discharge port cover 2.6 of the E-shaped fin is the discharge port. The discharge outlet is like a window, and the discharge outlet is equipped with a door that is like a window.

[0191] Example 4 (such as Figure 5 ):

[0192] Each of the above embodiments and all unloading wing rings, all all unloading fins on the same annular support, its receiving flow surface (side for driving) all faces the same circular motion direction, and its unloading surface (side...

example 2

[0207] Example 2 (eg Figure 8 ):

[0208] The method and steps of building a large tower by layered assembly and layer-by-layer heightening are as follows:

[0209] Such as Figure 8 In the left figure, a plurality of (such as 30 to 50) pillars or small towers 4.2 with suitable heights (such as 100 meters) are erected equidistantly on the bottom ring support 1.1, and then along each pillar or small towers 4.2 A ring-shaped bracket 1.1 (or a ring-shaped regular polygonal beam frame) is erected on the top of the upper layer, so that each pillar or small tower frame is connected as a whole, so that they can support and reinforce each other. If it is necessary to further strengthen, the non-adjacent pillars or small towers 4.2 can be connected with a straight beam frame according to a fixed rule (such as Figure 8 shown on the right). This forms the first floor of the large pylon.

[0210] If the small tower 5.1 still cannot be hoisted by a helicopter, it can be disassembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com