Open-type low-speed high-flow radial plunger pump

A large-flow, radial-column technology, used in pumps, multi-cylinder pumps, liquid-variable-capacity machines, etc., can solve the problems of large maintenance workload, low power collection rate and operating efficiency, complex transmission relationship, etc. And the effect of low failure rate, high power collection rate and operating efficiency, simple structure and transmission relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

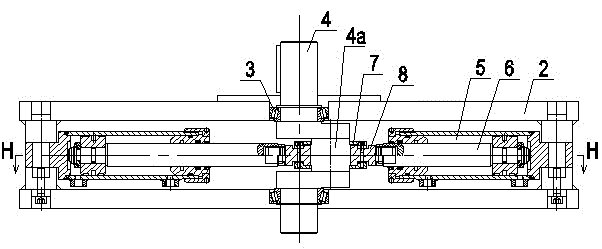

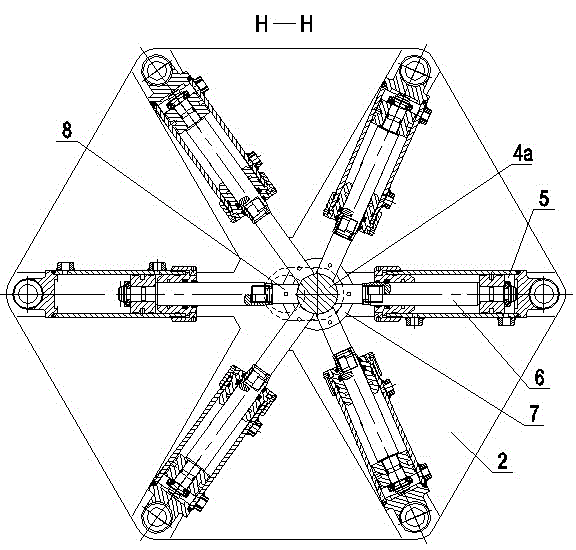

[0019] Such as figure 1 , figure 2 and image 3 As shown, the open low-speed high-flow radial piston pump includes a bracket 2, a crankshaft 4 mounted on the bracket 2 through bearings 3 at both ends, and six evenly distributed double-acting pumps are arranged around the eccentric section 4a of the crankshaft 4. Oil cylinder 5, the bottom of each double-acting oil cylinder 5 is hinged with support 2 through joint bearings, the piston rod 6 of each double-acting oil cylinder 5 is connected with the eccentric section 4a of the crankshaft through a rotatable connection structure, and the piston of each double-acting oil cylinder The stroke of the rod 6 is greater than twice the eccentricity of the crankshaft; the rotatable connection structure includes two sets of plates 7 slidingly mounted on the eccentric section 4a of the crankshaft and fasteners 8 fixedly connected with the respective piston rods 6, each fastener The front end of 8 is provided with an arc surface matche...

Embodiment 2

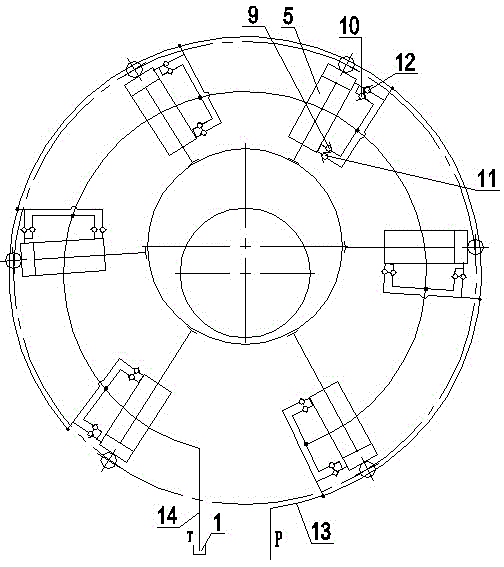

[0023] Such as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the open low-speed high-flow radial piston pump includes a bracket 2 and a crankshaft 21 mounted on the bracket 2 through bearings 3 at both ends. The crankshaft 21 includes coaxial sections at both ends, crank throws 21b and eccentric sections 21a, They are connected by fasteners such as bolts, and five evenly distributed double-acting oil cylinders 5 are arranged around the eccentric section 21a of the crankshaft 21. The bottom of each double-acting oil cylinder 5 is hinged to the bracket 2 through joint bearings, and each double-acting The piston rod 6 of the oil cylinder 5 is connected to the eccentric section 21a of the crankshaft through a rotatable connection structure, and the stroke of each double-acting oil cylinder piston rod 6 is greater than twice the eccentricity of the crankshaft; The rolling bearing 16 on the section 21a, the rod head 17 fixedly connected with the respective piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com