Method and device for high-speed and accurate measurement of tunnel section

A technology of precise measurement and measuring devices, which is applied in measuring devices, section drawing, and optical devices, etc., can solve the problems of high measurement accuracy and sampling rate, and achieve the effects of reducing image processing load, compact structure, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

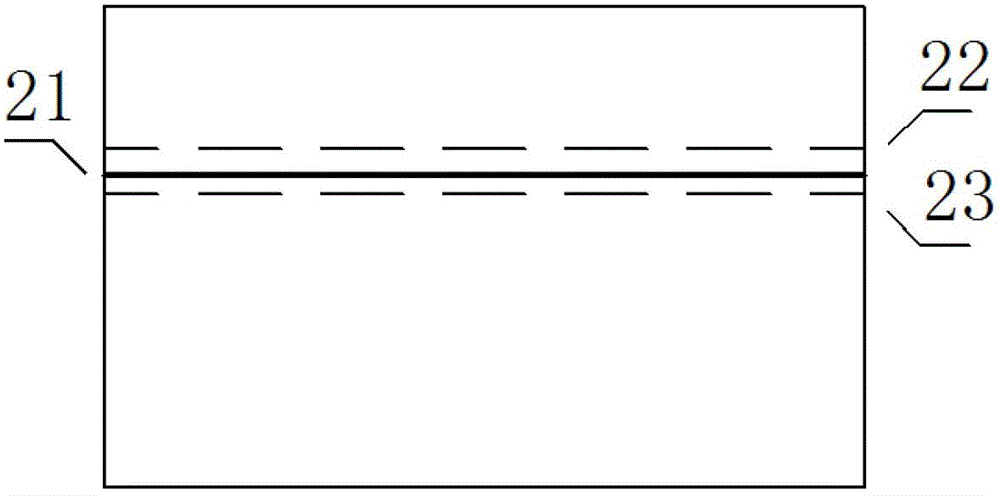

[0019] The present invention is mainly equipped on the railway inspection car, and the system starts to work when the inspection car passes through the tunnel. The laser scanning ranging system consists of two German SICK laser ranging sensors, which update the target distance in real time at a frequency of 35 frames per second, with an accuracy of 10mm. During the operation of the device, when the laser scanning ranging sensor detects that the target outline is assumed to be around a radius of 3m, this information is uploaded to the computer, and the computer calculates the spatial height of 3m corresponding to the camera at the corresponding angle of the photogrammetry system based on the pre-calibrated model. Near line 286 on the acquisition image, such as figure 2 Middle 21, while the target radius of 0.5m corresponds to the vicinity of the 240th and 317th lines of the image, such as figure 2 Middle 22 and 23. Then, the computer instructs the corresponding camera of th...

Embodiment 2

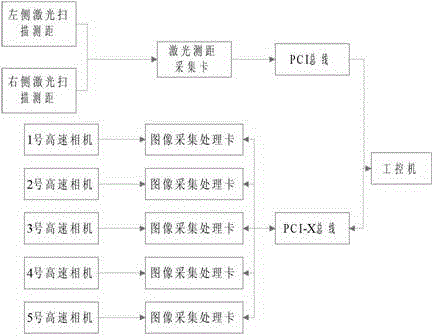

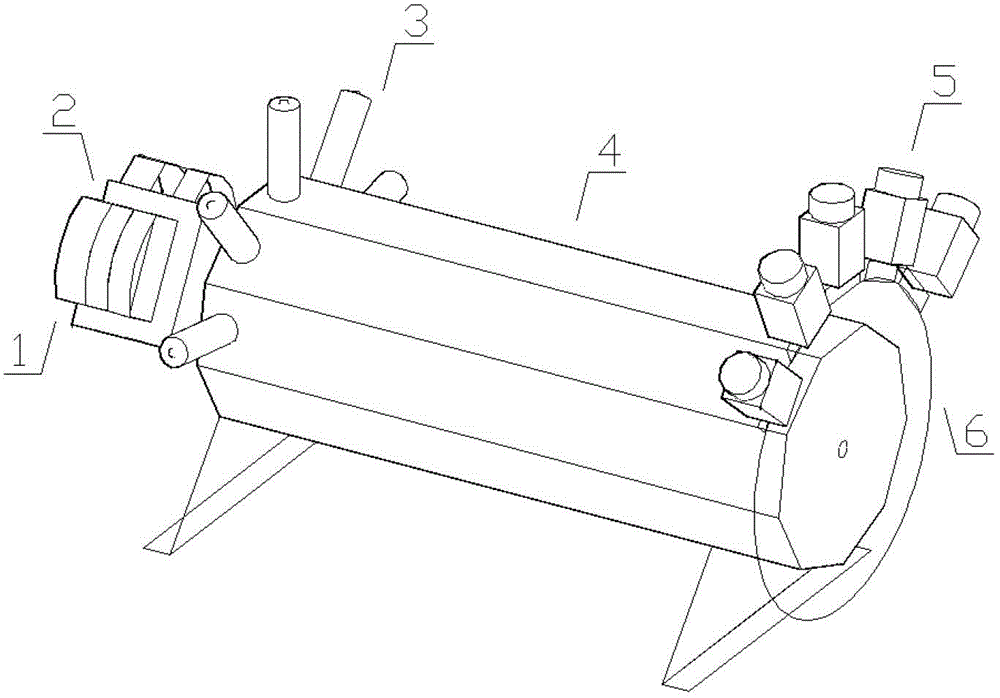

[0021] The whole measurement device is composed of three parts, (1) rough measurement module mainly composed of two laser scanning rangefinders; (2) photogrammetry module composed of multiple lasers and multiple high-speed industrial cameras; (3) data processing The system includes a plurality of image processing cards with FPGA as the processing core, a laser ranging acquisition card and a computer.

[0022] The laser ranging acquisition card collects the data of the laser scanning rangefinder and uploads it to the industrial computer, and the image processing card completes the image acquisition and model calculation functions of the camera, and corresponds to the camera one by one, such as image 3 shown. All the acquisition cards are connected with the industrial computer through the PCI bus. The image processing card performs multi-stage filtering on the image in the window and extracts the sub-pixel center of the light band by means of hardware circuit implementation, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com