Double-manipulator ultrasonic transmission detection device

A detection device and dual manipulator technology, applied in manipulators, measuring devices, program-controlled manipulators, etc., can solve problems such as difficulty in detecting large curved workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

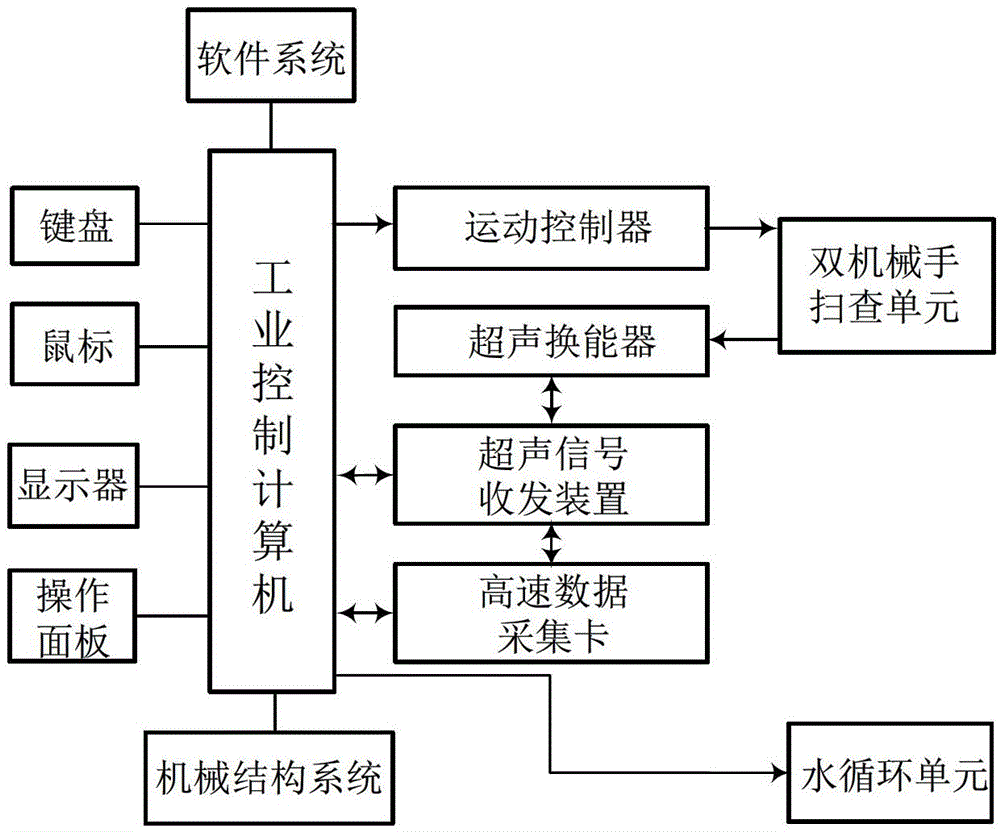

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

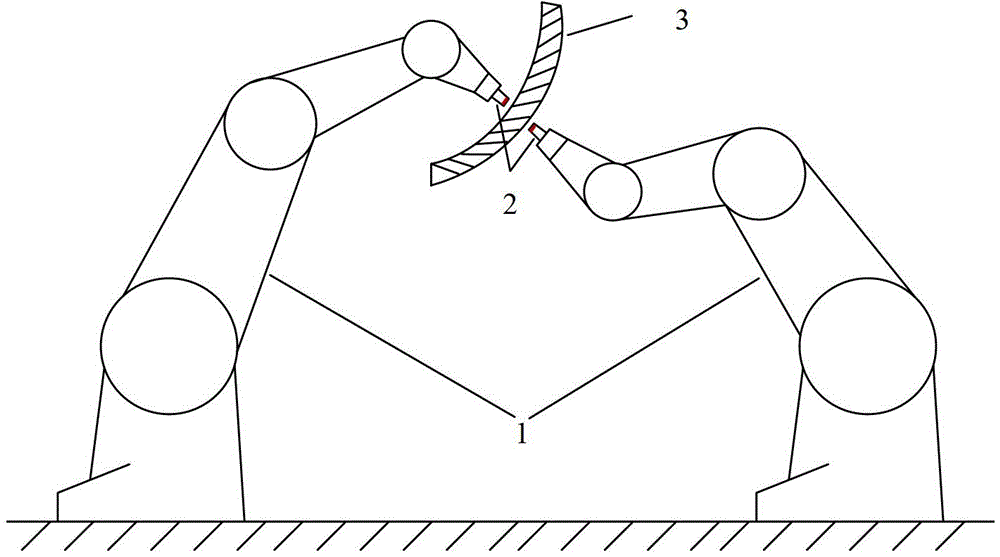

[0011] Specific embodiments of the present invention are described in detail below: see figure 2 Schematic diagram of dual-manipulator detection of curved surface composite materials. In the figure, 1 is the high-end manipulator, 2 is the water spray coupling probe, and 3 is the composite material workpiece to be tested.

[0012] When performing ultrasonic testing on the curved surface composite material workpiece, due to the existence of the surface curvature of the workpiece, the ultrasonic wave will generate quite complex propagation such as scattering, reflection, refraction, etc., in order to ensure that the ultrasonic signal is strongly incident into the workpiece, It is required that the ultrasonic transducer should automatically follow the change of the surface shape of the workpiece. When the curvature of the detected workpiece changes, the software system should control the high-end manipulator to drive the transducer to adjust the posture in time, that is, to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com