Two-beam interference photoetching method and system

A technology of double-beam interference and interference exposure, applied in the field of interference lithography, can solve the problems of long chemical etching processing time, limited processing format, cumbersome process, etc., and achieve the effect of low cost, high processing efficiency and smooth step surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

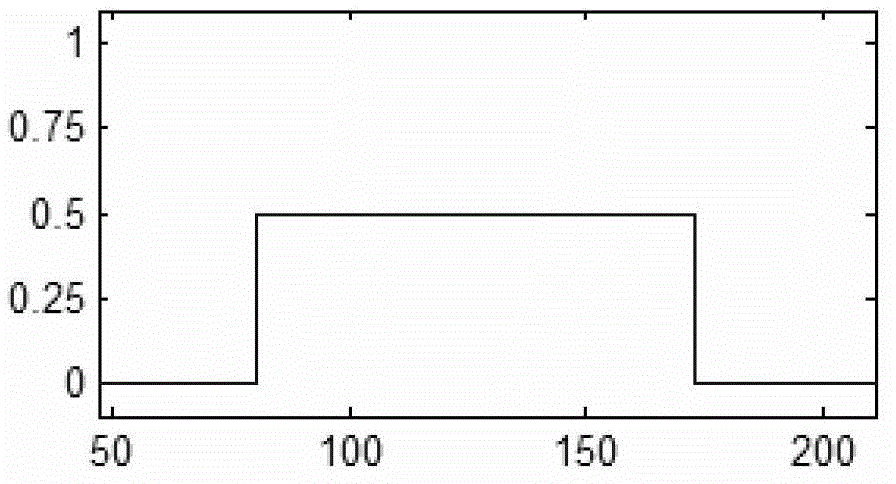

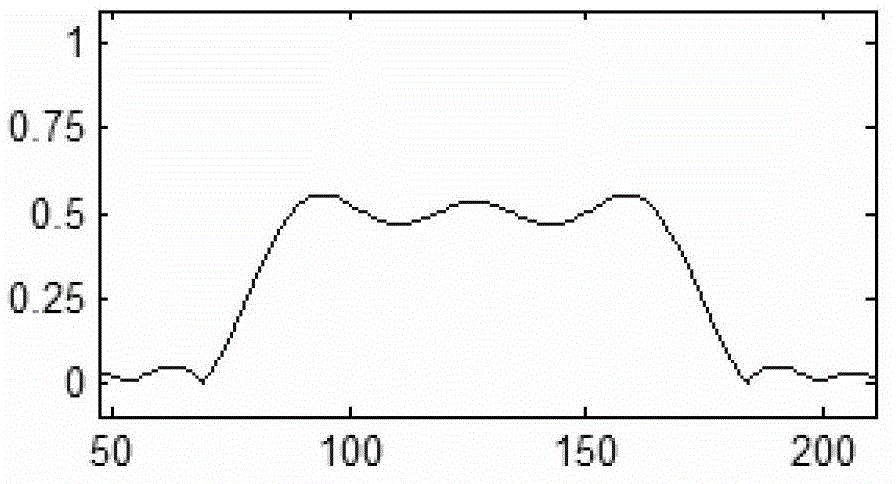

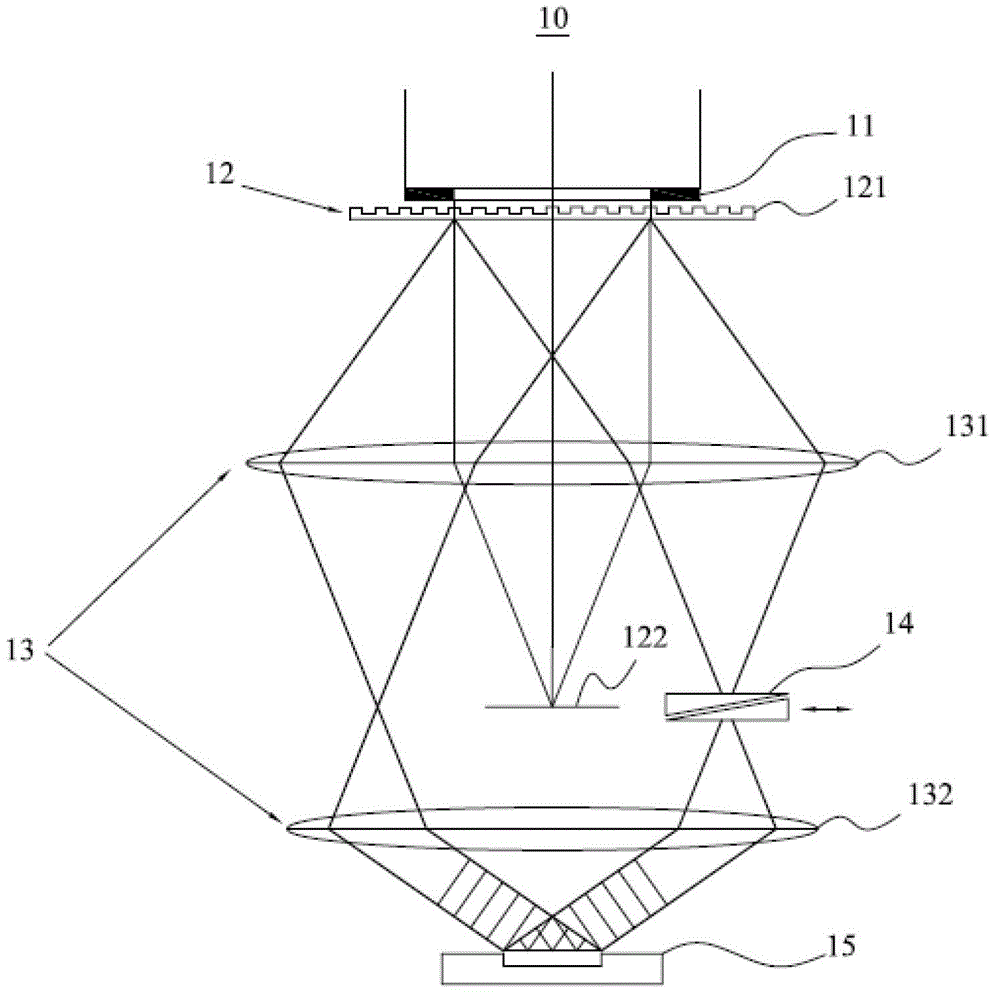

[0038] The present invention proposes a processing method based on interference lithography and multiple exposure superposition, the basic idea is to use interference lithography to obtain a light intensity distribution close to the ideal cosine type, and then make the cosine type light intensity dislocation through multiple exposures Superposition, so that the total light intensity distribution is a horizontal straight line, so as to obtain a flat-topped stepped structure.

[0039] In order to achieve the above purpose, the embodiment of the present invention discloses a double-beam interference lithography method. The two beams realize N times of interference exposure on the surface of the workpiece, and the misalignment value between two adjacent exposure positions is d I / N, where, N≥2, d I is the period of the light intensity distribution after exposure, and the complex amplitude distribution of the light field after the interference of the two beams is a cosine function....

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com