Medical apparatus with lubricity and manufacturing method of same

A medical device and wetting technology, which is applied in lubricating medical devices and their manufacturing fields, can solve problems such as stripping or elution into physiological saline solution, reduced metal adhesion, and unsuitability for medical devices to achieve safety Effect of increase, lubricity maintenance, possibility reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

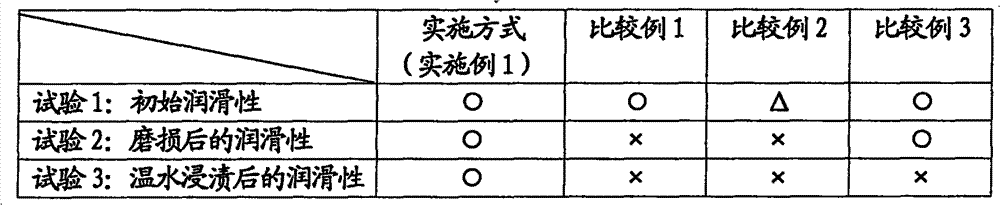

Examples

Embodiment 1

[0057] First, a solvent blend containing xylene and 1-butanol in a 2:1 weight ratio was prepared. Next, bisphenol A type epoxy resin prepolymer (product name: EPICLON 1010-70X (manufactured by DIC), epoxy equivalent, 450-500 (g / eq), viscosity: X-Z1 (25°C, Gardener) , non-volatile component 69-71 (weight %)) and polyamidoamine type curing agent (product name: LUCKAMIDE N-153-IM-165 (manufactured by DIC), active hydrogen equivalent, 472 (g / eq), viscosity : Z2-Z4 (25°C, Gardener), non-volatile components 64-66 (wt%)) were added to the solvent blend at a weight ratio of 1.5:1 and dissolved and diluted with 7 times the total amount To prepare mixed solution for interlayer coating.

[0058] A base material of a medical device made of metal was dipped in the mixed solution for interlayer film coating and then immediately drawn out and heated in an oven at 80° C. for 3 hours. A bisphenol A type epoxy resin was thus prepared, and an intermediate film made of the bisphenol A type epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com