Full micro-bubble mass transfer tower tray

A technology of micro-bubbles and mass transfer towers, applied in chemical/physical/physicochemical processes, fractionation, chemical instruments and methods, etc., can solve problems such as poor gas-liquid contact effect, large liquid level drop, liquid back-mixing, etc., to achieve The effect of reducing the spacing of the trays, reducing the height and increasing the opening ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

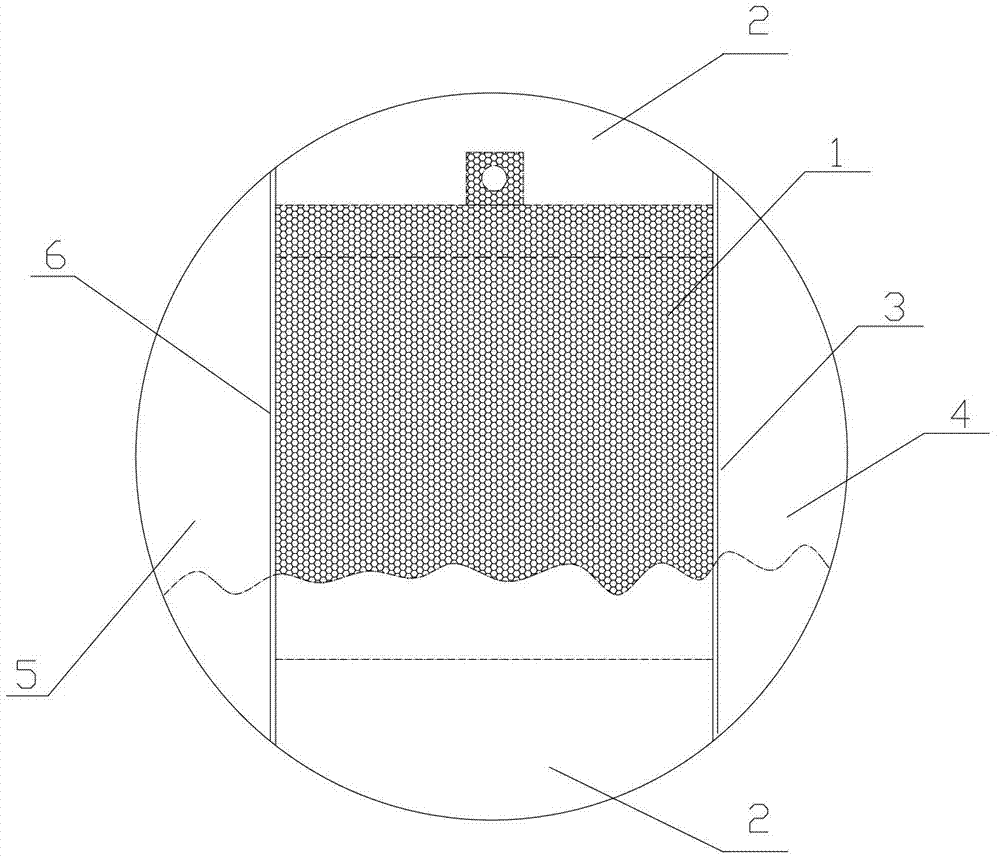

[0034] The plate tower is composed of a tray support 2, a microbubble integrated mass transfer tray 1 set on the tray support 2, a downcomer liquid receiving structure (downcomer 4, liquid receiving tray 5, inlet weir 6 and outlet weir 3) , where the overall structure of the tray is as follows figure 1 As shown, the entire tray is composed of microbubble mass transfer materials, made of ceramics, fixed on the tray support ring on the inner wall of the tower by bonding, the pore volume fraction is 90%, and the pore diameter is 0.1mm. The material has a uniform pore size. The radial cross-sectional area of the overall mass transfer material of the microbubbles accounts for 10% of the cross-sectional area of the entire tower. The thickness of the mass transfer material is 1mm, and its structure is a sponge-like porous structure.

[0035] When the tray is working, the liquid falls from the downcomer. Since the entire tray is made of microbubble mass transfer material, the gas ...

Embodiment 2

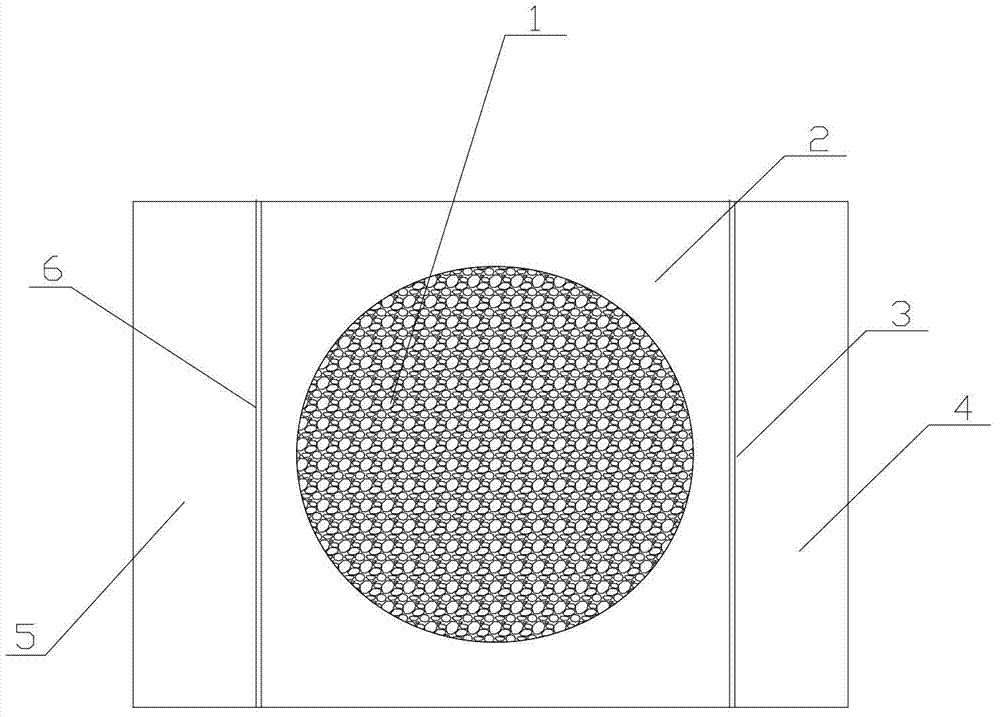

[0037] The plate tower is composed of a tray support 2, a microbubble integrated mass transfer tray 1 set on the tray support 2, and a downcomer and liquid receiving structure (downcomer 4, liquid receiving tray 5, inlet weir 6 and outlet weir 3) , where the overall structure of the tray is as follows figure 2 As shown, the entire tray is composed of microbubble mass transfer materials, made of silicon carbide, and fixed on the tray support ring on the inner wall of the tower by a buckle method. The pore volume fraction is 50-90%, and the pore diameter is 0.1-5mm, the material is non-uniform pore diameter, the whole material is composed of upper and lower layers of materials with different pore diameters, the upper material pore diameter is 0.1mm, the next material pore diameter is 5mm, the radial cross-sectional area of the microbubble overall mass transfer material occupies the entire tower 20% of the cross-sectional area, the thickness of the mass transfer material is 10mm...

Embodiment 3

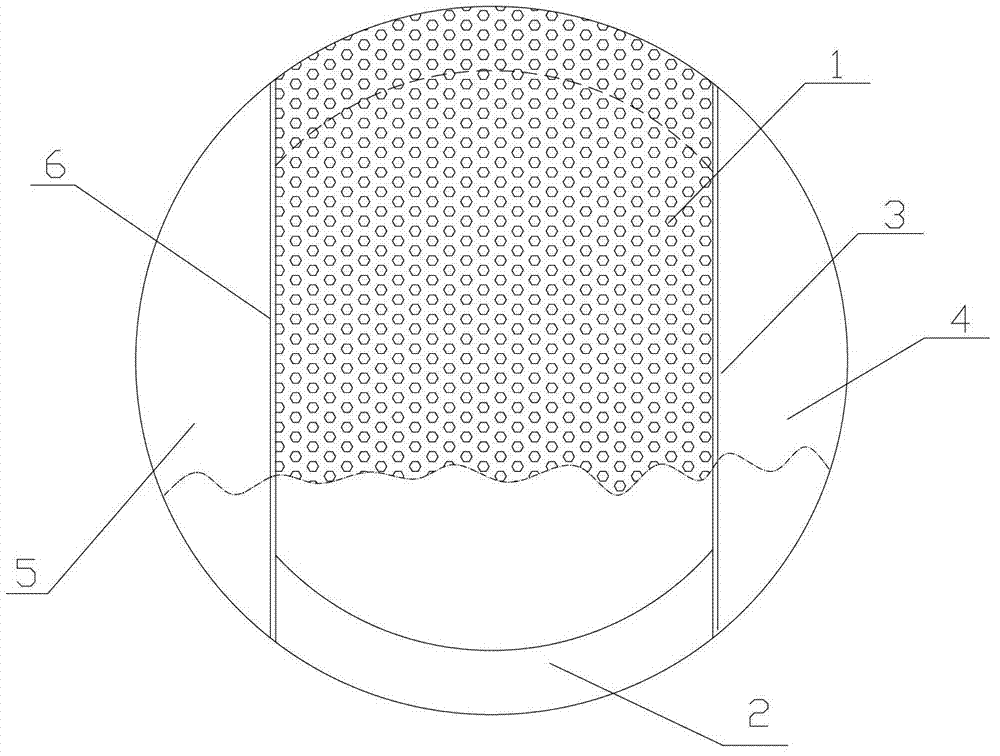

[0040] The plate tower is composed of a tray support 2, a microbubble integrated mass transfer tray 1 set on the tray support 2, and a downcomer and liquid receiving structure (downcomer 4, liquid receiving tray 5, inlet weir 6 and outlet weir 3) , where the overall structure of the tray is as follows image 3 As shown, the entire tray is made of microbubble mass transfer material, made of resin, fixed on the tray support ring on the inner wall of the tower by screws, the pore volume fraction is 50%, the pore diameter is 5mm, and the material is Uniform pore size, the radial cross-sectional area of the microbubble overall mass transfer material accounts for 30% of the cross-sectional area of the entire tower, the thickness of the mass transfer material is 100mm, and its structure is a bundled porous structure.

[0041] When the tray is working, the liquid falls from the downcomer. Since the entire tray is made of microbubble mass transfer material, the gas phase passes upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com