Automatic expansion joint system and automatic expansion joint control method

An expansion joint and automatic technology, applied in the direction of heat exchange equipment, etc., can solve the problems affecting the quality of expansion joints, the production quality and production efficiency of shell and tube heat exchangers, etc., so as to improve the accuracy of expansion joints, improve production quality and Production efficiency and the effect of ensuring production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

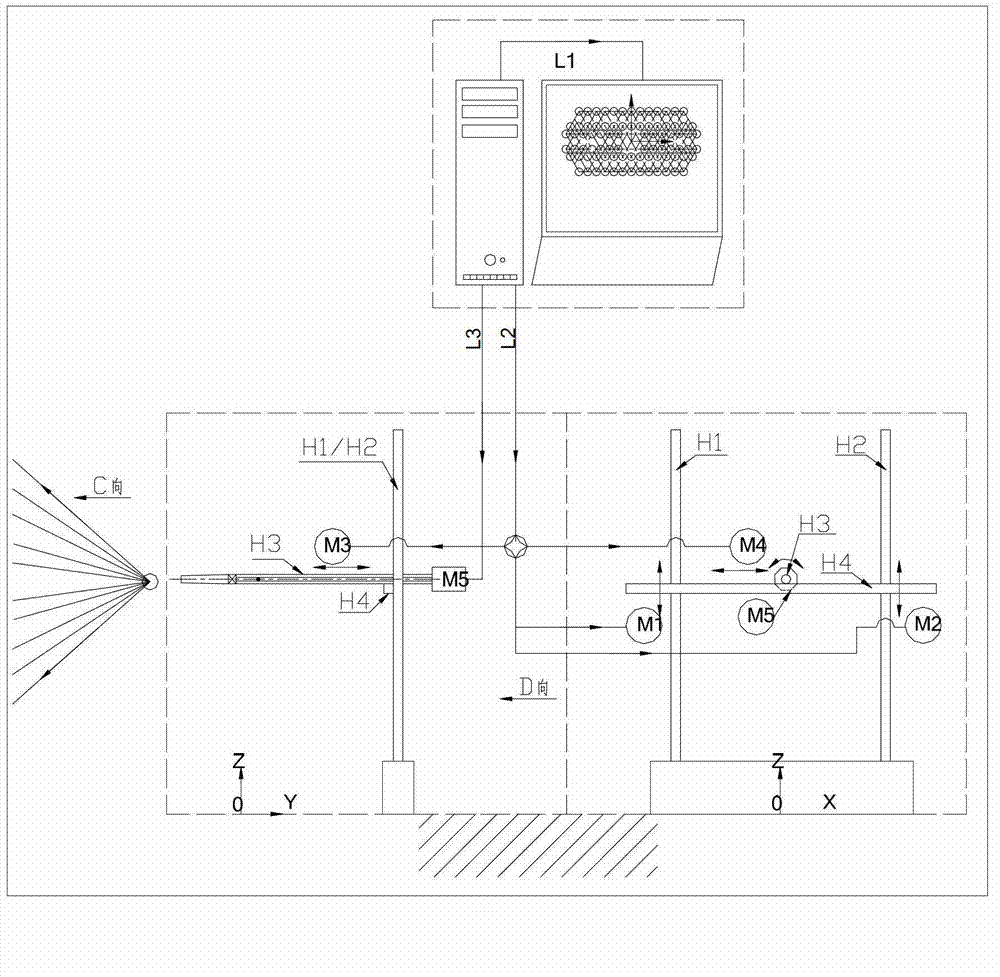

[0061] Please refer to the attached figure 1 , is a structural schematic diagram of an automatic expansion joint system disclosed in the present invention.

[0062] The automatic expansion system includes: a computer integrated control and display subsystem L1, a tube expander servo control subsystem L2 and a tube expander expansion control subsystem L3 respectively connected to the computer integrated control and display subsystem L1.

[0063] The computer integrated control and display subsystem L1 is the core of the entire automatic expansion joint system, which can store, display and print various expansion joint parameters. In addition, the subsystem is equipped with automatic control software, which can automatically control the servo control subsystem L2 of the tube expander and the tube expander Expansion joint control subsystem L3 action.

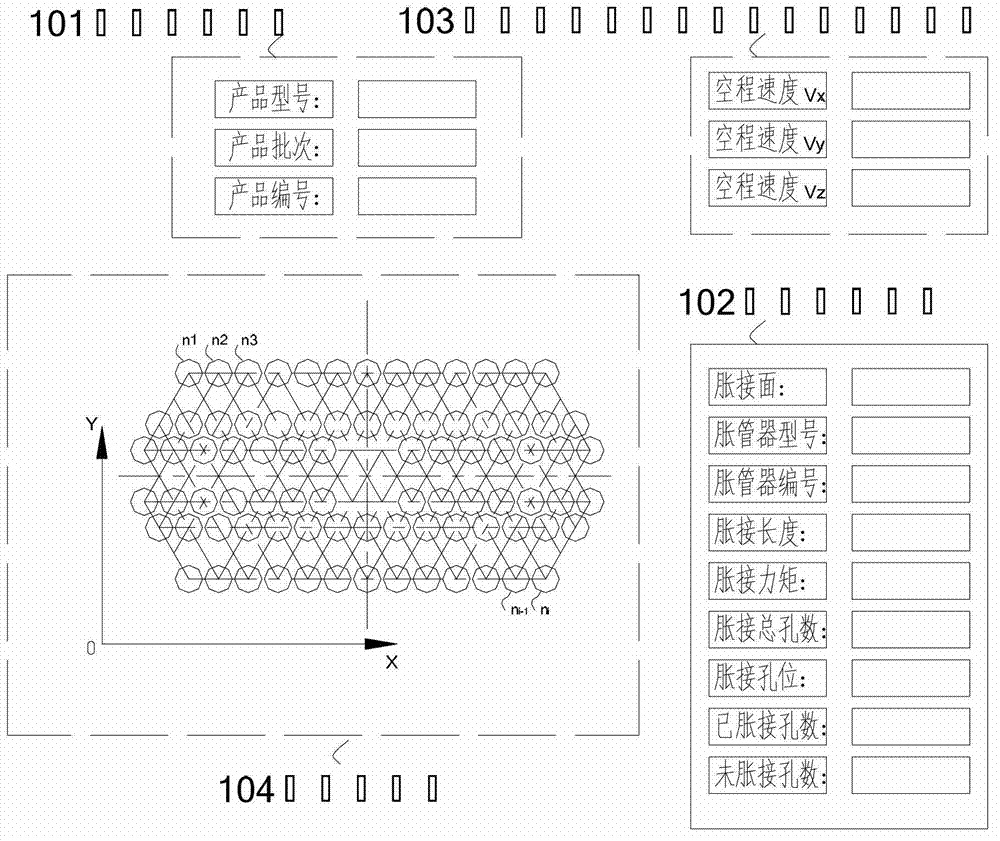

[0064] For clarification, please refer to the attached figure 2 , is the display interface of the computer integrated control...

Embodiment 2

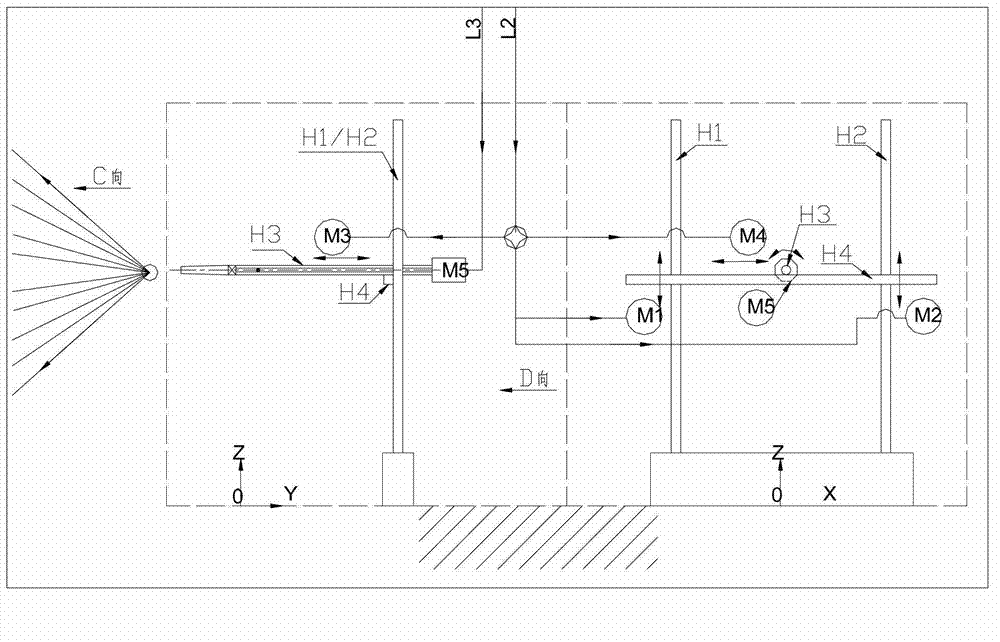

[0071] Please refer to the attached image 3 , is a specific structural diagram of the tube expander servo control subsystem L2 and the tube expander expansion control subsystem L3 in the automatic expansion joint system disclosed in the present invention.

[0072] The tube expander servo control subsystem L2 includes: a first shaft H1, a second shaft H2, a beam H4, a first drive M1, a second drive M2, a third drive M3 and a fourth drive M4, wherein:

[0073] The first axis H1 and the second axis H2 are perpendicular to the ground, the first axis H1 is connected to the first drive M1, the second axis H2 is connected to the second drive M2, and the first drive M1 and the second drive M2 synchronously control the main shaft of the tube expander to move up and down along the vertical direction of the first axis H1 and the second axis H2;

[0074] The main shaft of the tube expander is connected to the third drive M3, and the third drive M3 controls the main shaft of the tube exp...

Embodiment 3

[0084] Please refer to the attached Figure 4 , is a structural schematic diagram of another automatic expansion system disclosed in the present invention.

[0085] The automatic expansion system includes: computer integrated control and display subsystem L1, tube expander servo control subsystem L2 connected to the computer integrated control and display subsystem L1, tube expander expansion control subsystem L3 and self-lubricating Control subsystem L4.

[0086] Among them, the structure and function description of the computer integrated control and display subsystem L1 and the tube expander servo control subsystem L2 and tube expander expansion control subsystem L3 respectively connected to the computer integrated control and display subsystem L1 please refer to the implementation The relevant descriptions of Example 1 and Embodiment 2 will not be repeated here.

[0087] The self-lubrication control subsystem L4 controls the lubrication of the expanding head of the tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com