Control device for residual stress and strain along with welding of titanium alloy

A residual stress and strain control technology, used in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of large deformation resistance, difficult deformation, and difficult to achieve deformation of titanium alloy thin-walled structures, and achieve low external load and low strain. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

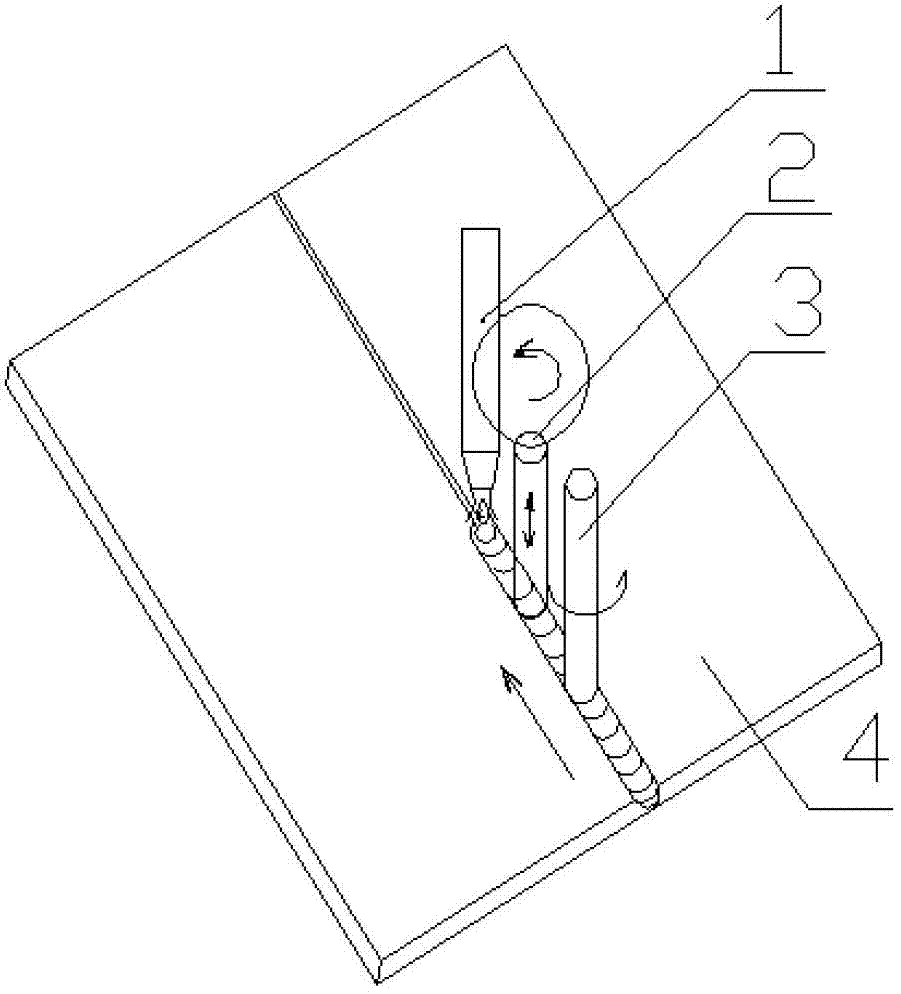

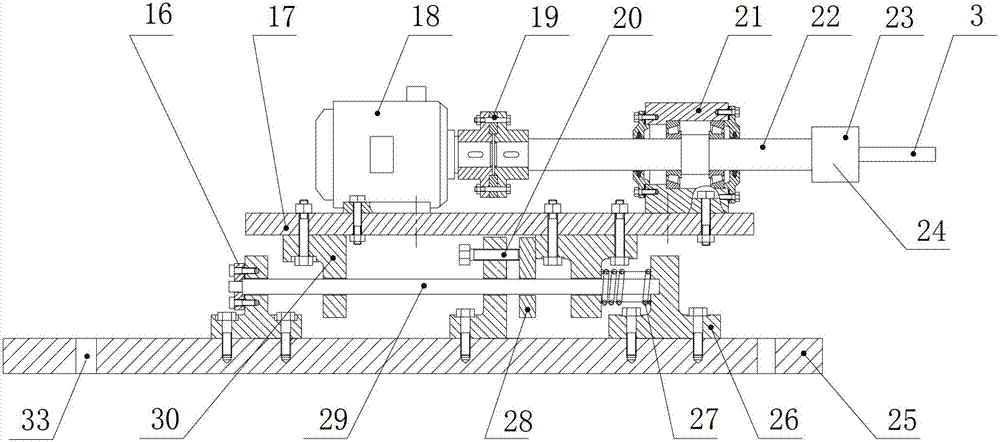

[0024] A device for controlling residual stress and strain of titanium alloy with welding, consisting of a front point-by-point extrusion device 12 and a rotary extrusion device 24;

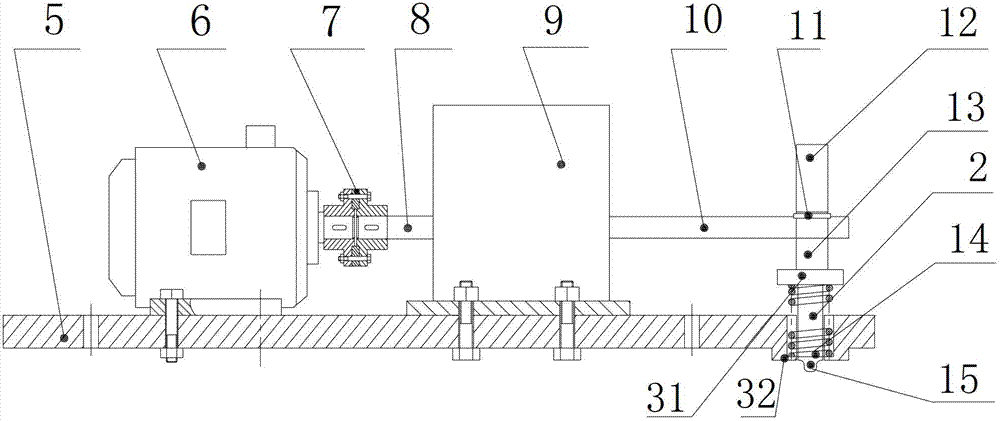

[0025] Such as figure 2 As shown, the front point-by-point extrusion device 12 includes a first bottom plate 5 with a front point-by-point extrusion rod through hole, and a DC motor 6 and a worm gear reducer 9 are respectively arranged on the first bottom plate 5; The output shaft of 6 is connected to the input shaft 8 of the worm gear reducer with a reduction ratio of 20 through the first coupling 7, which plays the role of input power. The output shaft 10 of the worm gear reducer is in phase with the cam 13 in the form of linear motion connection; the front point-by-point extrusion rod 2 with pressure head 15 is arranged in the through hole of the front point-by-point extrusion rod; The rotation of the cam 13 constantly promotes the front point-by-point extrusion rod 2, thereby achieving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com