Working table for machining mold

A technology of mechanical processing and workbench, which is applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high processing cost, prolonging the delivery time of molds, and difficult processing of ordinary machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

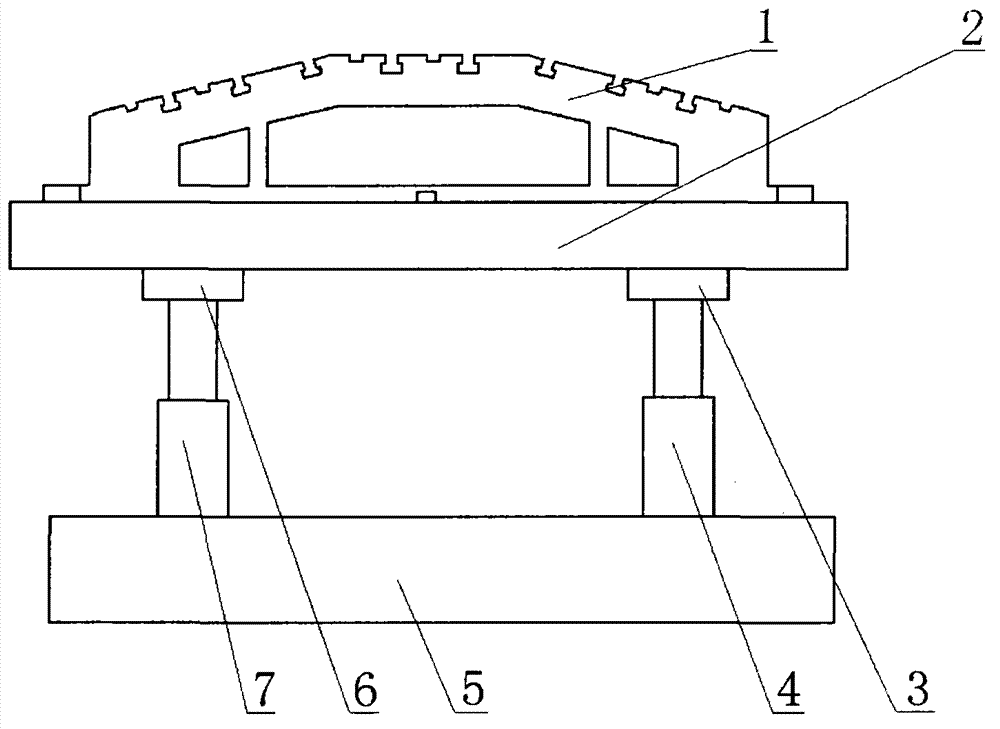

[0012] Such as figure 1 , figure 2 As shown, the workbench for mold machining includes a base 5, a platen 2, an angle platen 1, a first lifting cylinder 4 and a second lifting cylinder 7, and the first lifting cylinder 4 and the second lifting cylinder 7 are located on the base 5 and the platform. Between the plates 2, the angle platen 1 is located above the platen 2, and below the platen 2 there is a movably connected platen first support portion 3 and a platen second support portion 6, and the platen first support portion 3 and the second platen support portion The top of a lift cylinder 4 is fixedly connected, and the top of the second support portion 6 of the platen is fixedly connected with the top of the second lift cylinder 7 .

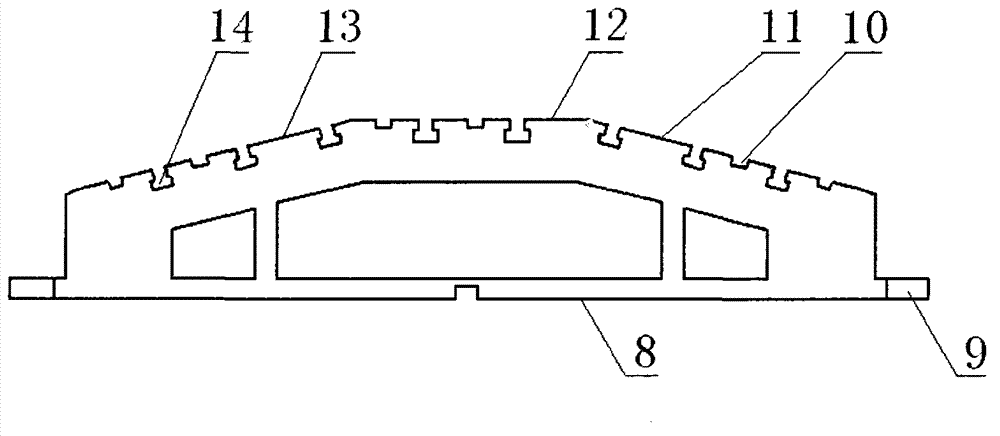

[0013] The angle platen 1 has a horizontal angle platen bottom surface 8, a first inclined clamping surface 11, a horizontal clamping surface 12 and a second inclined clamping surface 13, the first inclined clamping surface 11, the second inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com