Mould used for manufacturing curved surface honeycomb aluminium plate

A honeycomb aluminum plate and mold technology, applied in the directions of lamination auxiliary operation, lamination device, lamination, etc., can solve the problems of wasting wood, high production cost, unfavorable energy saving and environmental protection, etc., to change material waste, improve processing and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

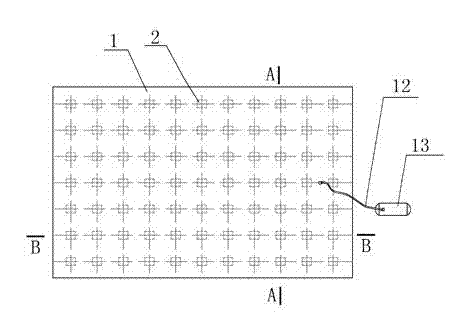

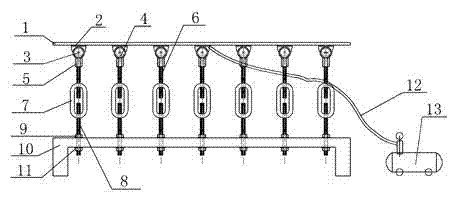

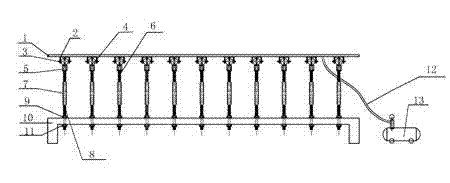

[0019] The support 2 of the ball hinge is arranged in a square under the rectangular steel plate 1, the row spacing and the column spacing are both 200mm, and the welding seam is used to connect; then the steel ball 4 is placed in the ring of the ball hinge connector 5, and then used The pin bolt 3 connects the support 2, the steel ball 4 and the connecting piece 5 into a spherical hinge, and installs each spherical hinge in turn; the turnbuckle bolt assembly is composed of the upper bolt 6, the turnbuckle nut 7 and the lower bolt 8, and the upper bolt 6 is screwed into the nut cavity of the ball hinge connector 5, and each set of turnbuckle bolt assemblies is also installed under the rectangular steel plate 1; each lock nut 9 is installed on the lower bolt 8, and each lower bolt assembly 8 is placed in the installation hole of steel frame 10, is screwed on lock nut 11, and then the framework of the present invention has just formed. One end of the air pressure pipeline 12 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com