Vehicle safety belt braid

A technology for seat belts and vehicles, which is applied in the field of vehicle seat belt webbing, which can solve the problems of reducing the overall protection effect of seat belt devices, excessive compression of occupant's chest and abdomen, and reduction of webbing area, so as to avoid damage to ribs and internal organs, The effect of reducing extrusion and facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

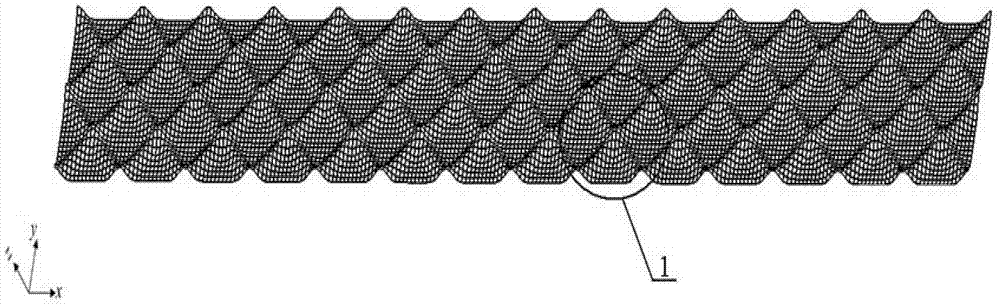

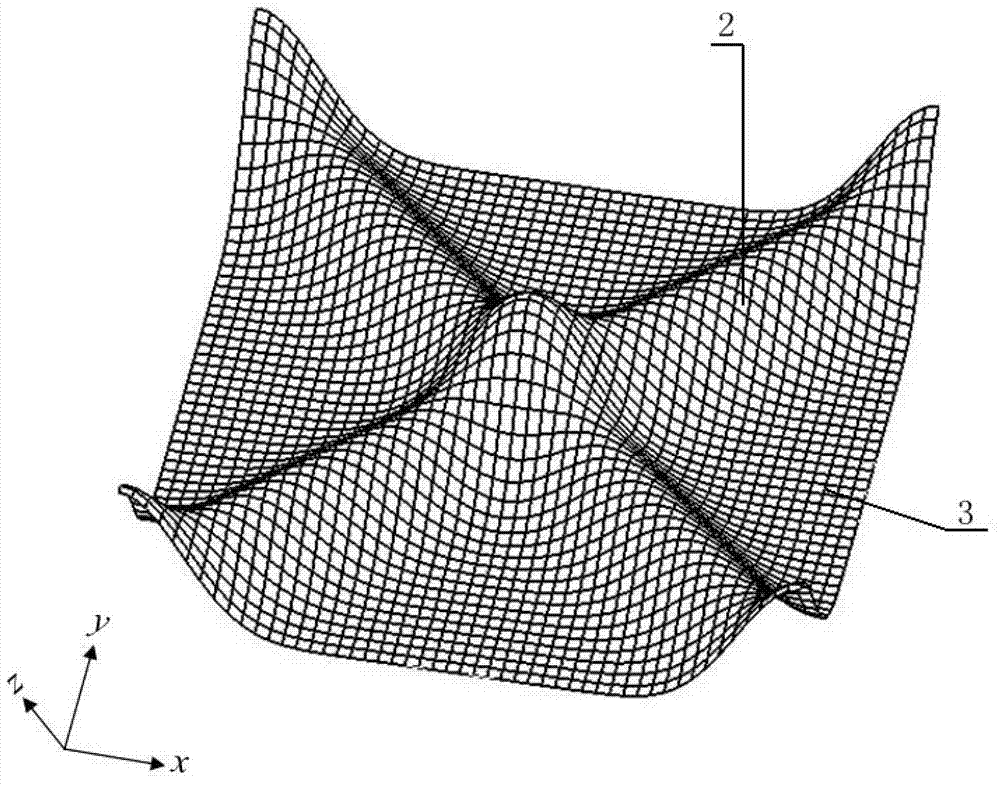

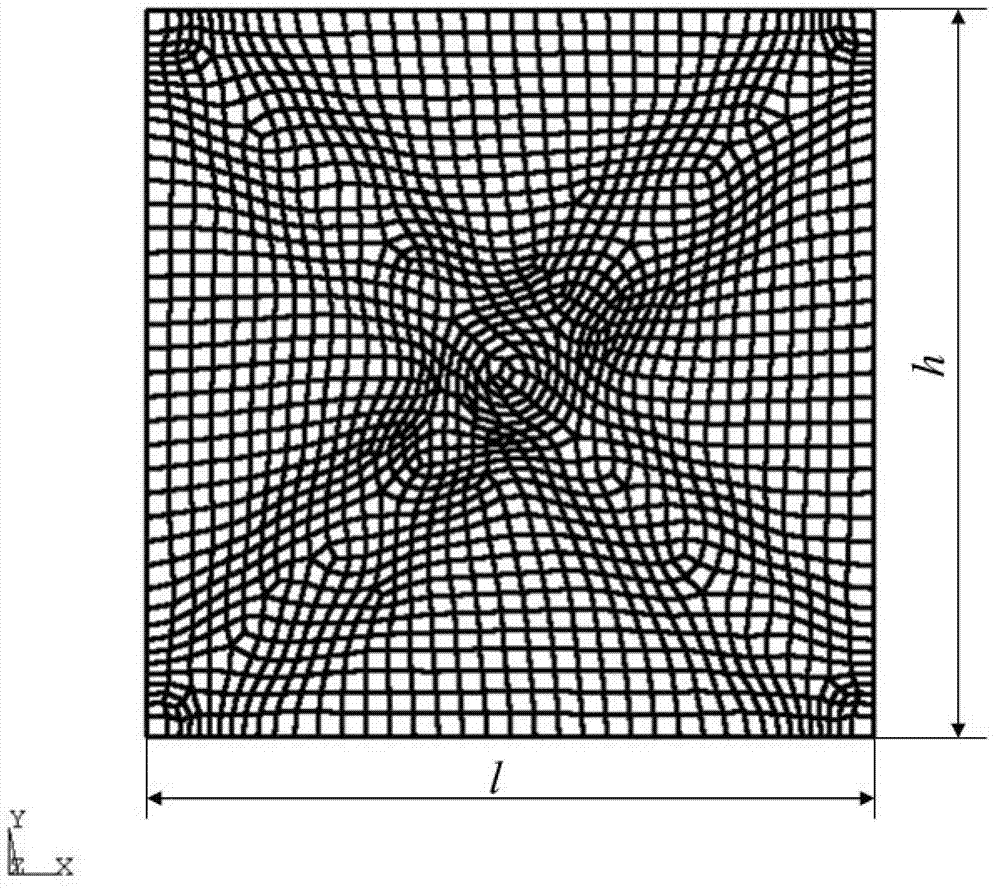

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] The negative Poisson's ratio characteristic of the safety belt webbing of the present invention is mainly realized by the auxetic effect of the accumulative auxetic unit 1 . Poisson's ratio (Poisson's ratio) μ is defined as the ratio of the transverse strain to the longitudinal strain when the material is subjected to longitudinal tension or compression, namely:

[0028] μ = - ϵ y ϵ x - - - ( 1 )

[0029] Among them, ε y is the transverse strain of the material, ε x is the longitudinal strain of the material. The so-called negative Poisson's ratio characteristic, that is, the range of Poisson's ratio μ is -1~0. When a negat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com