Packing defect detecting device and detecting method for boxed cigarettes

A defect detection and cigarette technology, which is applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low sensitivity, complex detection structure, and easy interference, and achieve simplified detection structure, simple device structure, and unresolved problems. deterministic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

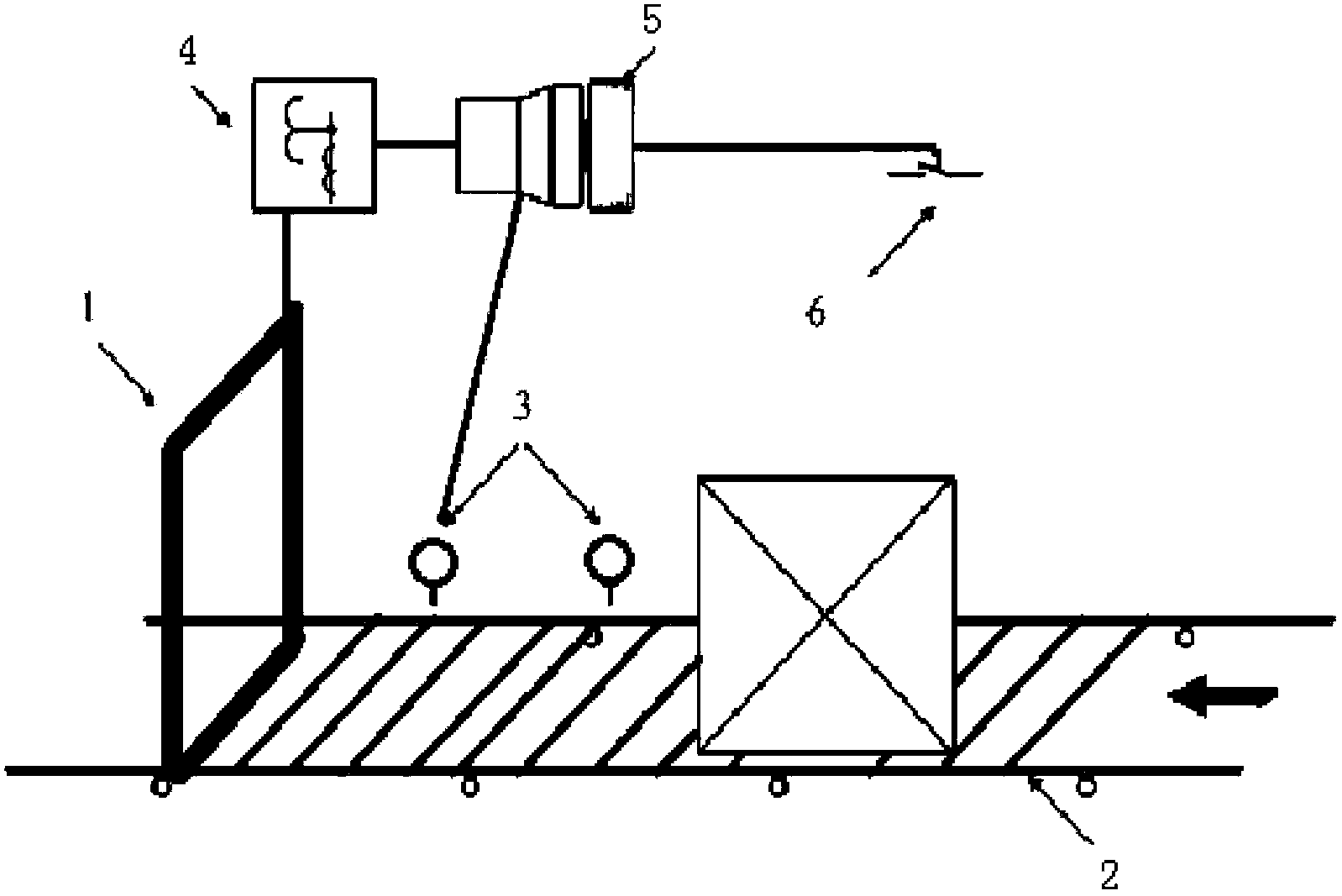

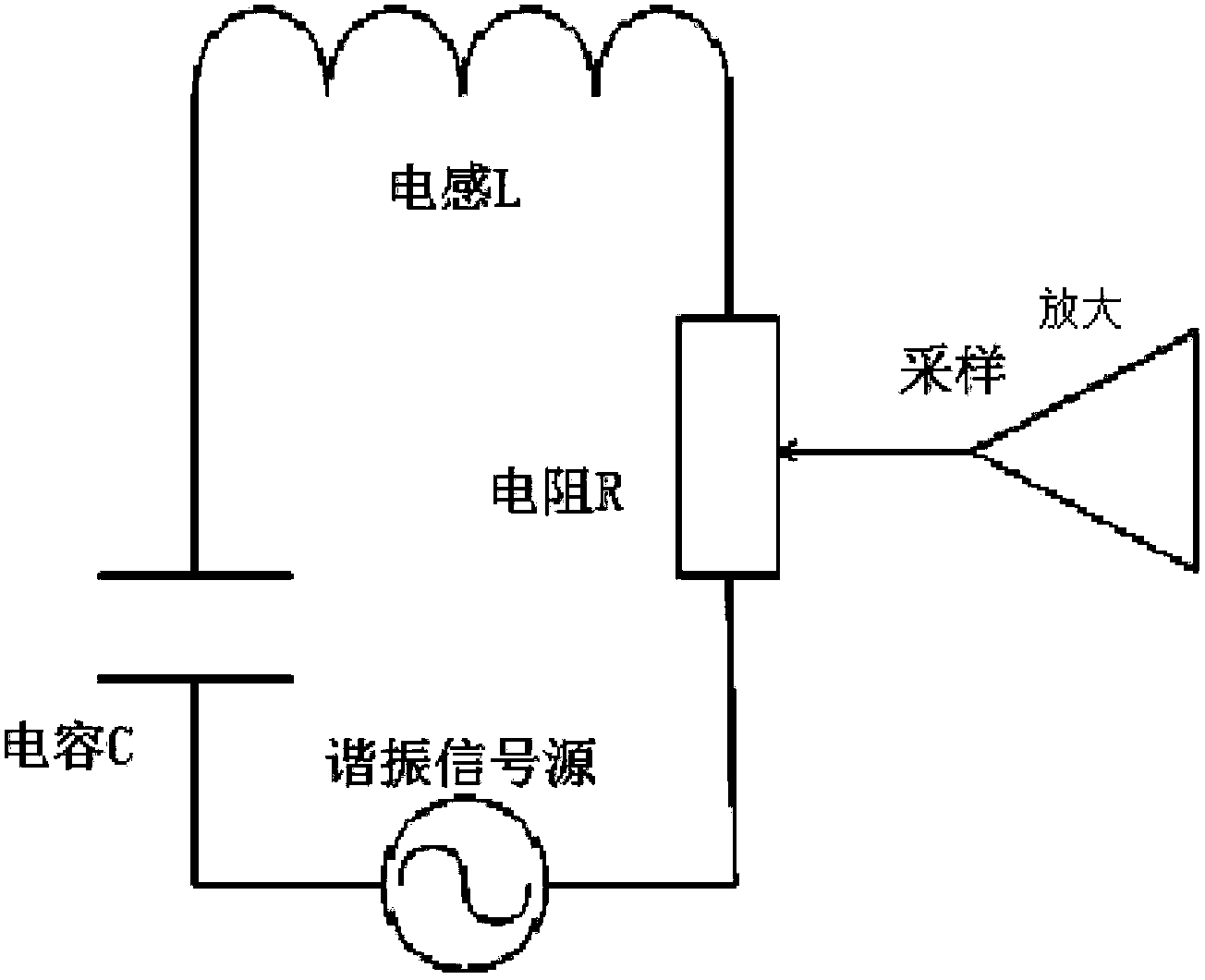

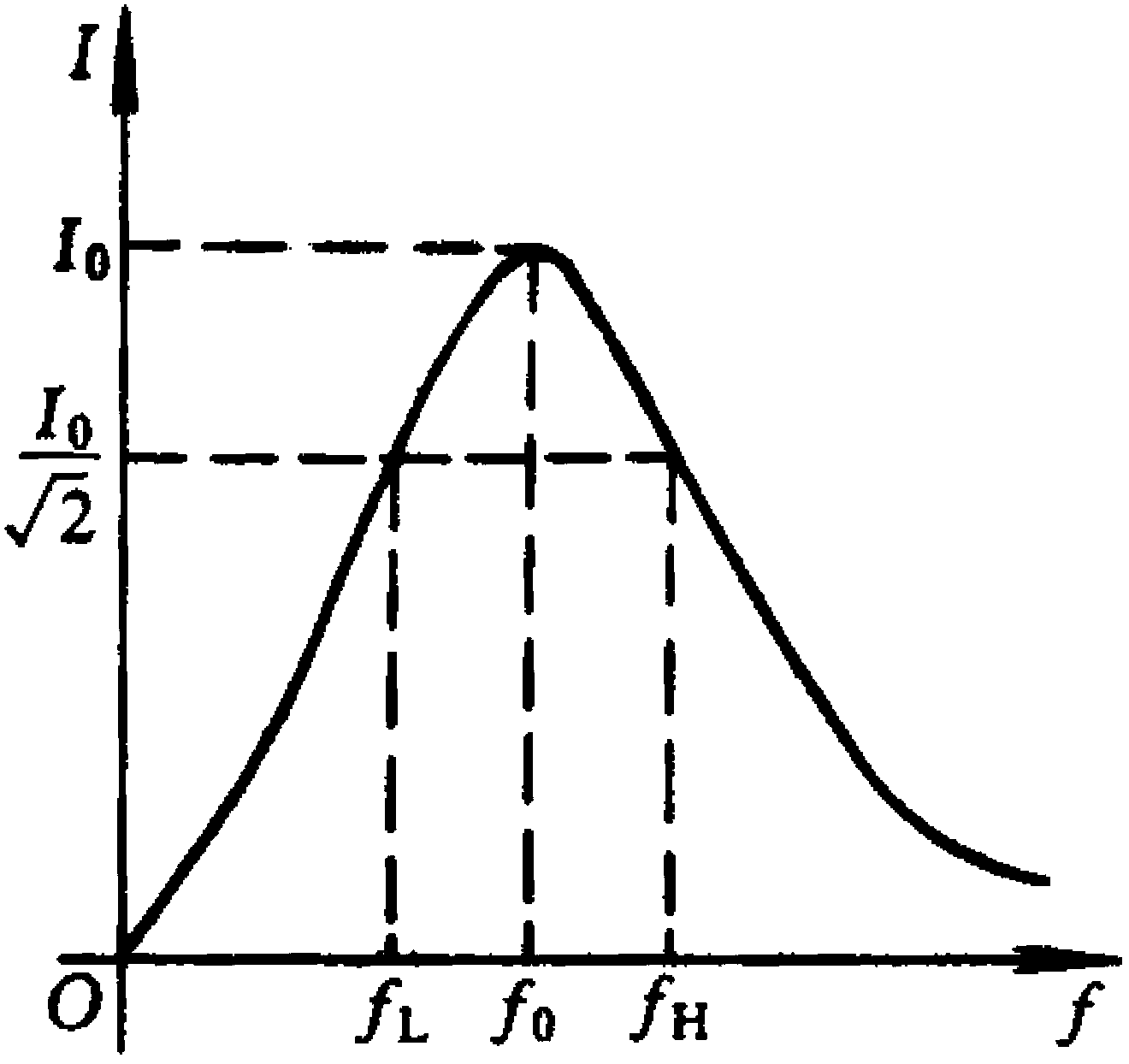

[0024] figure 1 Shown is a boxed cigarette packaging defect detection device of the present invention, the device includes two photoelectric switches 3 that are arranged on the conveyor belt 2 that transports the boxed cigarettes and serve as detector start switches and conveyor belt speed sensing devices respectively. On the conveyor belt and behind the photoelectric switch, the gate coil 1 is used as the inductance L of the LCR series resonant circuit. The inductance L is connected in series with the capacitor C and the resistor R to form the LCR series resonant circuit. The inductance L in the LCR series resonant circuit is used as a detector, and the LCR The voltage drop of the resistor R in the series resonant circuit is detected and linearly amplified to form a signal pickup circuit 4 , the signal pickup circuit 4 is electrically connected to the signal processing system 5 , and the signal processing system 5 is electrically connected to the conveyor belt switch 6 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com