Method for degrading phenol in wastewater

A technology of phenol and waste water, applied in the direction of chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., to achieve the effect of simplifying the operation procedure, shortening the treatment time, and shortening the treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

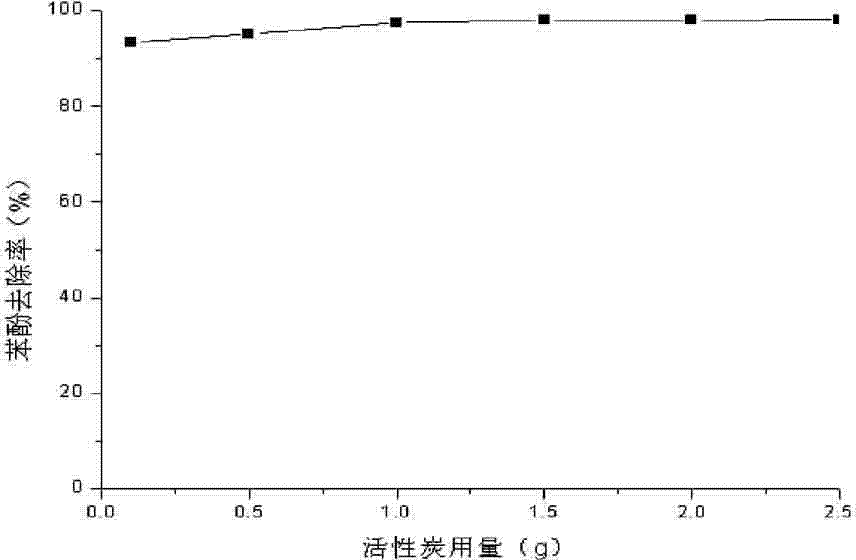

Image

Examples

Embodiment 1

[0016] Example 1 The acquisition of phenol-degrading bacteria

[0017] Proceed as follows:

[0018] (1) Take the activated sludge polluted by phenol (the activated sludge in this example is taken from the aeration tank of the biological treatment plant of the coking plant of Benxi Iron and Steel Group Corporation), and shake the sludge sample on the shaker for about 2 hours , to break up the bacteria micelles and release free bacteria;

[0019] (2) Dilute the crushed activated sludge by 10-fold dilution method, spread it on beef extract peptone solid medium, and cultivate it at 32°C;

[0020] (3) Take out the above-mentioned cultivated plate samples, pick out the colonies with fast growth and bright fluorescence, and insert them into the beef extract peptone solid medium with a phenol concentration of 1500 mg / L, and keep the temperature at 32°C Incubate for 24 hours. Increase the concentration of phenol in the solid medium step by step to 3000mg / L;

[0021] (4) Inoculate...

Embodiment 2

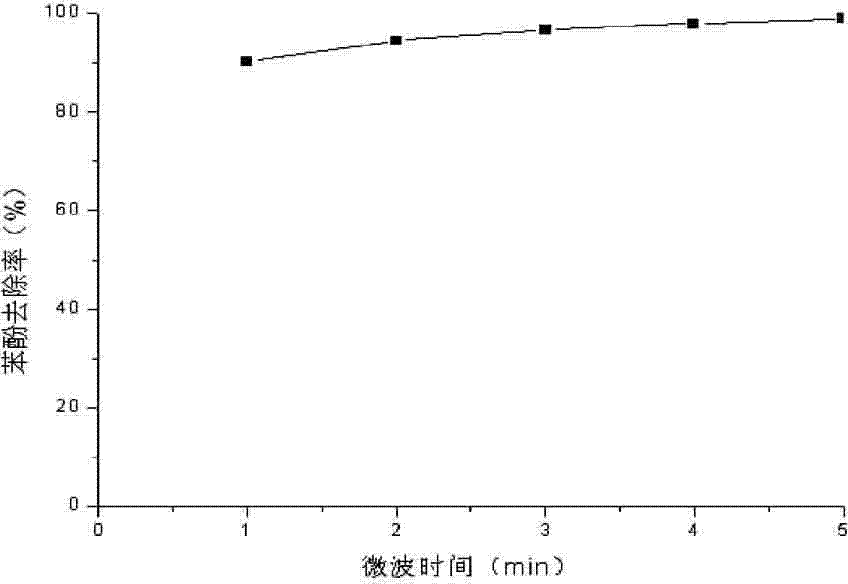

[0028] Take 100mL water sample with a phenol concentration of 600mg / L in a 250mL Erlenmeyer flask, add 1.0g of activated carbon, and microwave in a microwave oven with a microwave power of 600W, and the microwave time is selected as 1, 2, 3, 4, and 5 minutes respectively. After the microwave was finished, take out the Erlenmeyer flask, cool to room temperature, filter, put the bacterial suspension of the strain h32a2 into the Erlenmeyer flask according to the inoculum amount of 1%, respectively, the pH is 7.5, and place it on a shaker for 24 hours at a constant temperature of 32°C. Determination of the removal rate of phenol after taking out, such as figure 2 .

[0029] Such as figure 2 It can be seen that the removal rate of phenol increases rapidly with the increase of time before the microwave irradiation time is 3 minutes, but the change range is not significant after 3 minutes. Therefore, the chosen reaction time was 3 min.

Embodiment 3

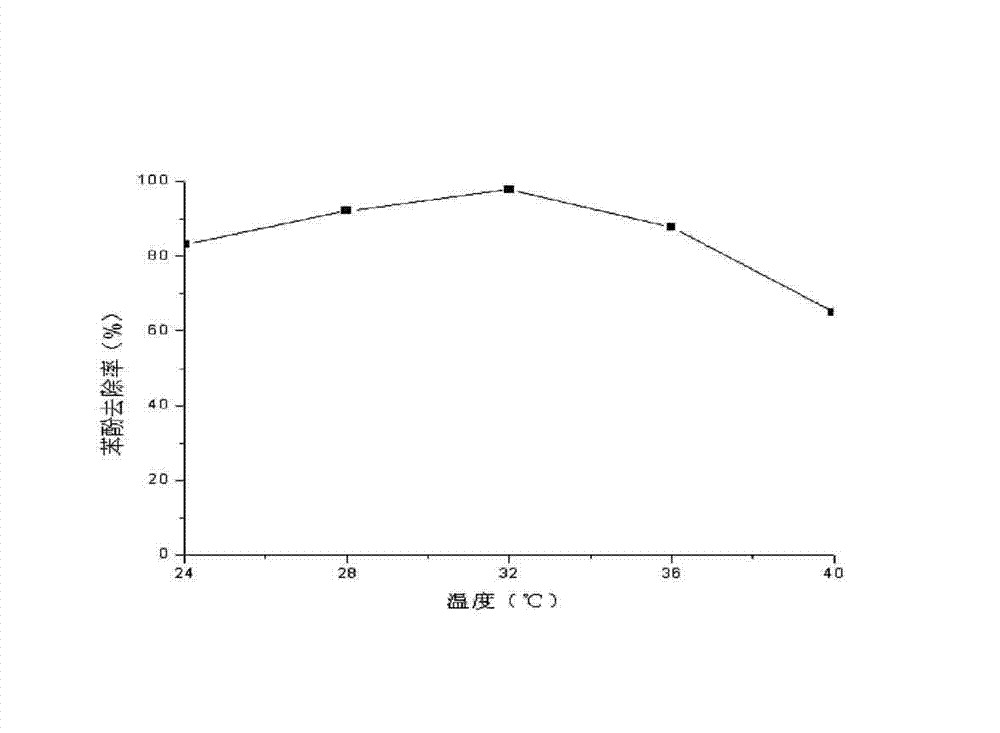

[0031] Take 100 mL of water sample with a phenol concentration of 600 mg / L in a 250 mL Erlenmeyer flask, add 1.0 g of activated carbon, and place it in a microwave oven with a microwave power of 600 W for 3 minutes. After the microwave was finished, take out the Erlenmeyer flask, cool it to room temperature, filter, put the bacterial suspension of strain h32a2 into the Erlenmeyer flask according to the inoculum amount of 1%, respectively, the pH is 7.5, and place it on a shaker for 24 hours at constant temperature for shaking culture, respectively set Set the shaker temperature at 24°C, 28°C, 32°C, 36°C and 40°C, and measure the removal rate of phenol after taking it out, as image 3 .

[0032] Such as image 3 As shown, when the temperature is 32°C, the removal rate of phenol reaches 97.83%. At the highest temperature of 40℃, the removal rate of phenol was low, only 65.03%. It can be seen from the figure that the phenol removal rate starts from the lowest temperature of 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com