Method and apparatus for laser shock processing of weldment at ultralow temperature

A technology of laser shock strengthening and laser welding, which is applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of strict welding process requirements, and achieve the effects of achieving consistency, increasing dislocation density, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

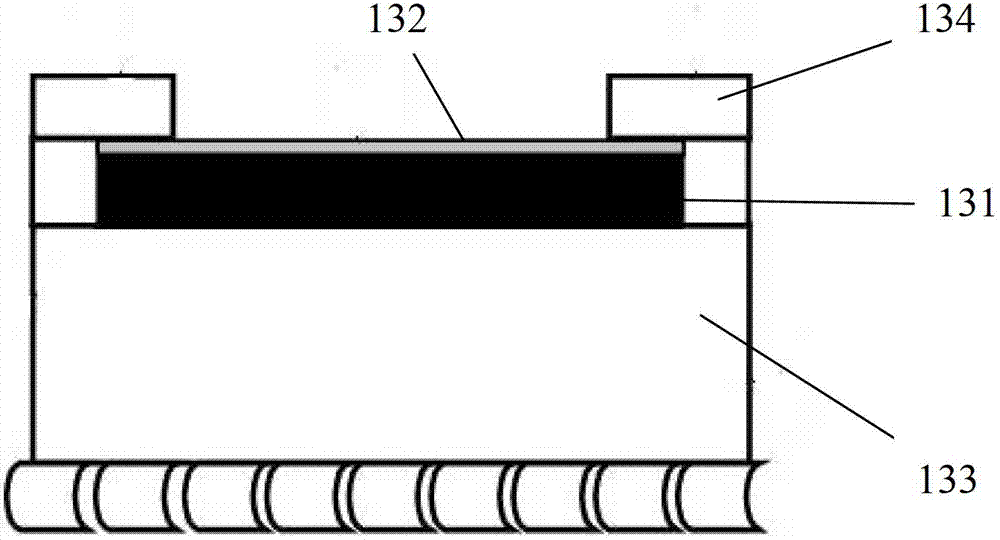

[0034] The embodiment of the present invention discloses a method for laser shock strengthening of welded parts in an ultra-low temperature environment, including:

[0035] (1) Provide a weldment that has a weld zone;

[0036] (2) Dip the welded piece into liquid nitrogen, and perform laser shock strengthening treatment on the weld seam area.

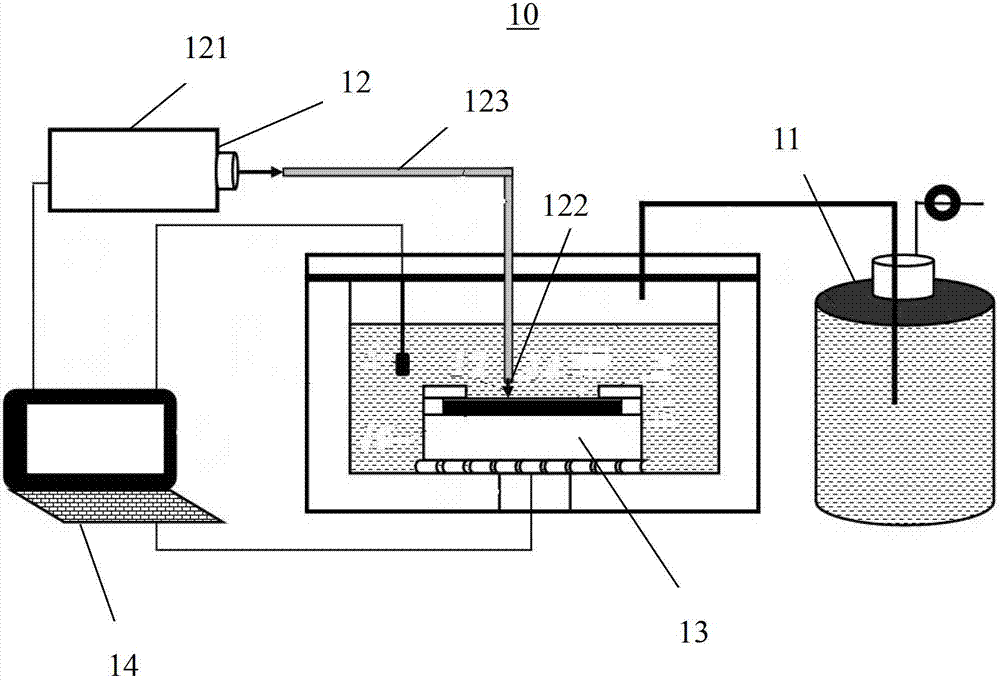

[0037] Correspondingly, the present invention also discloses a laser welding device, comprising:

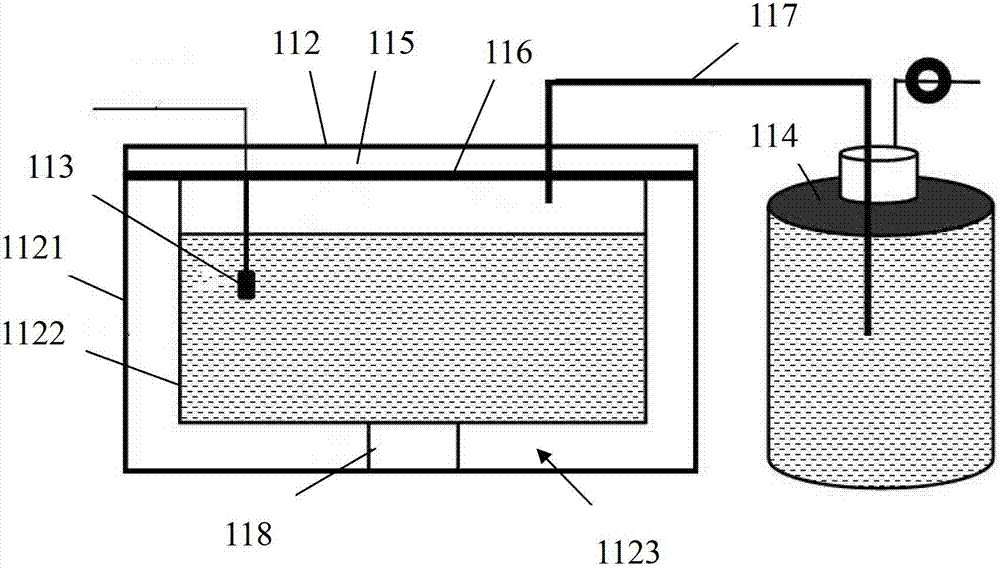

[0038] The ultra-low temperature control device includes a liquid nitrogen storage tank, the liquid nitrogen storage tank contains liquid nitrogen, and the welding parts are immersed in the liquid nitrogen;

[0039] The laser strengthening device emits laser beams and performs laser shock strengthening treatment on the weld seam area.

[0040] The weldment is placed in a liquid nitrogen ultra-low temperature environment. Liquid nitrogen is used as a low-temperature auxiliary environment and as a confinement layer in the process of laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com