Evaporation device

A technology of evaporation and evaporation source, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of damage, evaporation source failure, high cost, etc., and achieve the effect of low cost, prevention of looping, and difficulty in failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

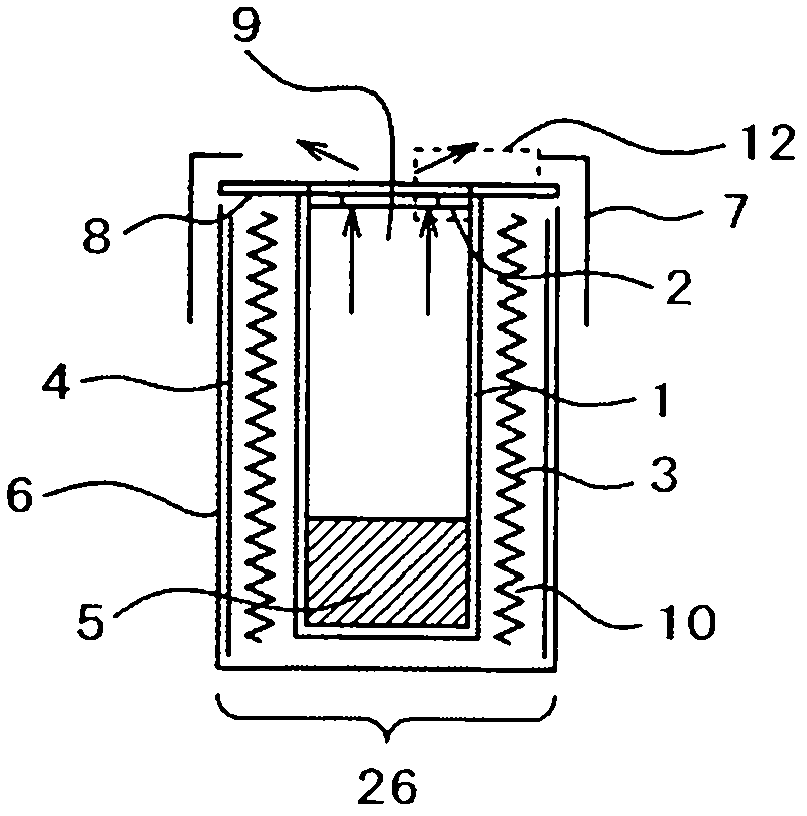

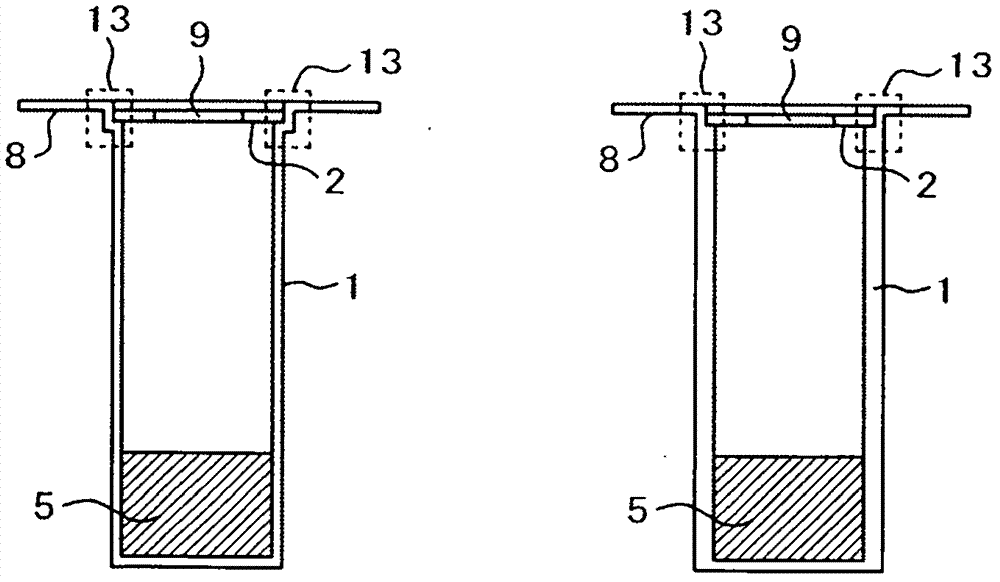

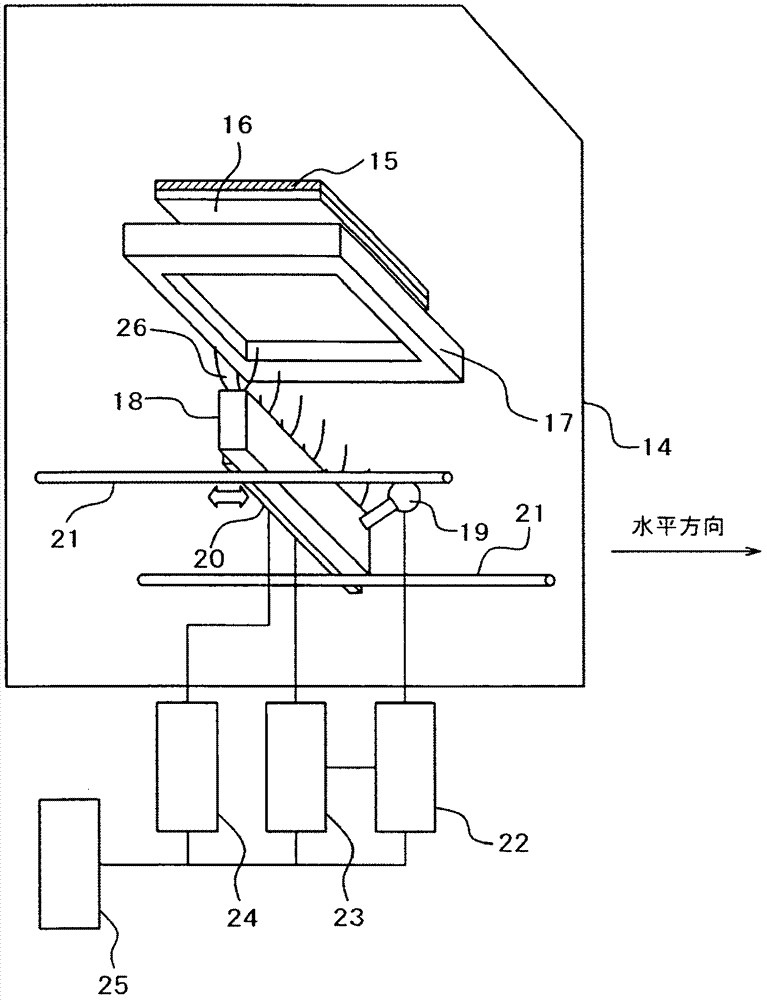

[0049] From Figure 1 to Figure 4 and Figure 17 is a diagram illustrating this embodiment. figure 1 It is a schematic sectional view of the evaporation source of the evaporation apparatus of this Example. Figure 17 It is a schematic sectional view of the evaporation source of the evaporation apparatus for comparison with Example 1. figure 2 It is an explanatory drawing of the crucible of the vapor deposition apparatus of Example 1. image 3 It is a schematic configuration diagram of a vapor deposition apparatus using the vapor deposition source of Example 1. FIG. Figure 4 It is a process diagram showing an example of an organic EL display production process.

[0050] First, in order to compare with Example 1, the Figure 17 The evaporation source of the evaporation device will be described. Figure 17 The evaporation source consists of a crucible (main body) 1 with a crucible flange 8, a heater (heating device) 3, a reflector 4, an evaporation material 5, an outer c...

Embodiment 2

[0078] Figure 5 It is a schematic sectional view of the evaporation source of the evaporation apparatus of Example 2. exist figure 1 The reflector 4 shown in is omitted for simplicity. In the following drawings, the descriptions are also omitted within the scope that no particular description is required. Only for example 1 figure 1 The different sections are explained. The same applies to Examples after Example 3. This embodiment is characterized in that the structure 2 having the nozzle is exposed outward from the fixing member 7 , in other words, is exposed outward in the vertical direction with respect to the plane including the crucible flange 8 . In addition, the opening of the structure 2 having the nozzle is upward.

[0079] Since the structure 2 with the nozzle is outward from the fixing member 7, in other words, it is a structure exposed to the outside in the vertical direction relative to the plane including the crucible flange 8, therefore, the upward cree...

Embodiment 3

[0085] Figure 7 It is a schematic sectional view of the evaporation source of the evaporation apparatus of Example 3. This embodiment is characterized in that the structure 2 having the nozzle is exposed from the fixture 7 to the outside of the crucible 1 and the crucible flange 8 , and the opening 9 of the nozzle structure 2 faces the horizontal direction.

[0086] In this embodiment, too, the nozzle structure 2 is exposed from the fixture 7 to the outside of the crucible 1 and the crucible flange 8 , so that upward creep of Al is less likely to occur as the temperature of the crucible 1 decreases. Since the Al vapor has a cut 12 on the path from the nozzle to the heating chamber, it is also difficult for the Al vapor to go back to the heating chamber 10 .

[0087] Figure 8 It is a schematic configuration diagram of the vapor deposition apparatus of Example 3. The evaporation source 18 composed of a plurality of vertical evaporation source units 26 arranged parallel to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com