Method for inhibiting secondary electron emission of microwave component surface by adopting nanostructure plating layer

A technology for secondary electron emission and microwave components, which is applied in nanotechnology, coating, sputter plating, etc., can solve the problems of poor conductivity of the oxide film and unfavorable microwave signal transmission, etc., and achieve the improvement of discharge threshold and secondary electron emission Coefficient reduction, the effect of reducing the secondary electron emission coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

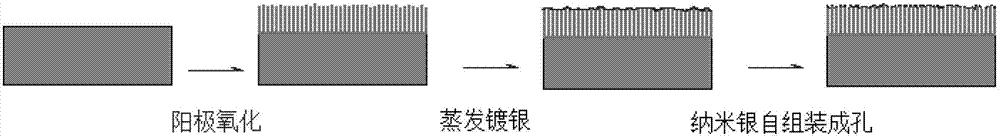

[0027] The process of constructing nano-trap on typical aluminum alloy substrate is as follows: figure 1 shown.

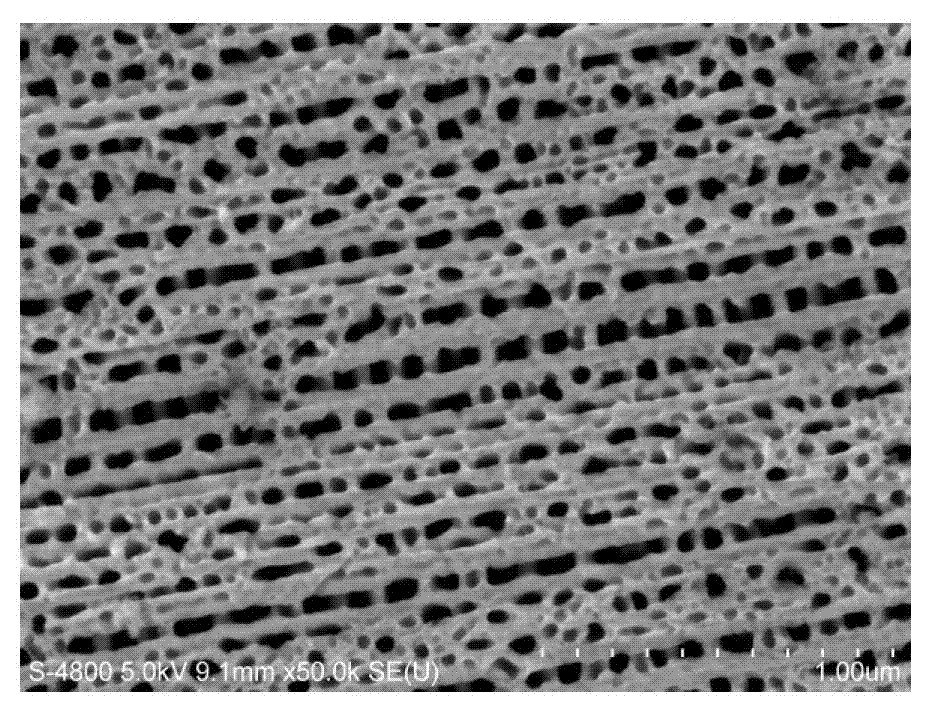

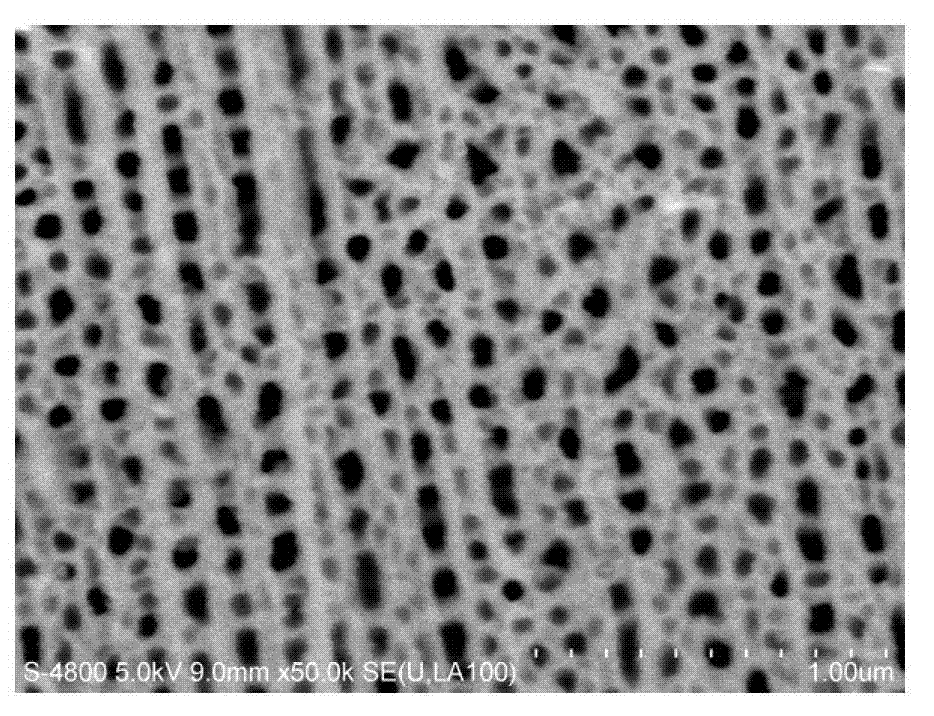

[0028] This patent proposes a method for effectively reducing the secondary electron emission coefficient on the surface of high-power microwave components. The core of this method is to use a series of treatment processes such as anodic oxidation, evaporative silver plating, and vacuum annealing on the basis of ensuring good electrical conductivity of microwave components to self-assemble nano-silver on the surface of the regular porous oxide film of aluminum alloy to form nano-trap. structure, in order to achieve the purpose of inhibiting SEY. The method mainly includes the following processing steps: After necessary cleaning, the microwave components are firstly coated with protective glue to protect the surface that does not need to be treated, and then electrochemically corroded by phosphoric acid to form a pore diameter of about 100nm on the surface of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com