A sandwich insulation wall and wallboard based on ultra-high toughness cement-based composite material

A composite material, ultra-high toughness technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of poor durability, large thickness, easy to crack, etc., to achieve the effect of good economy, easy transportation and high damage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with technical solutions and accompanying drawings.

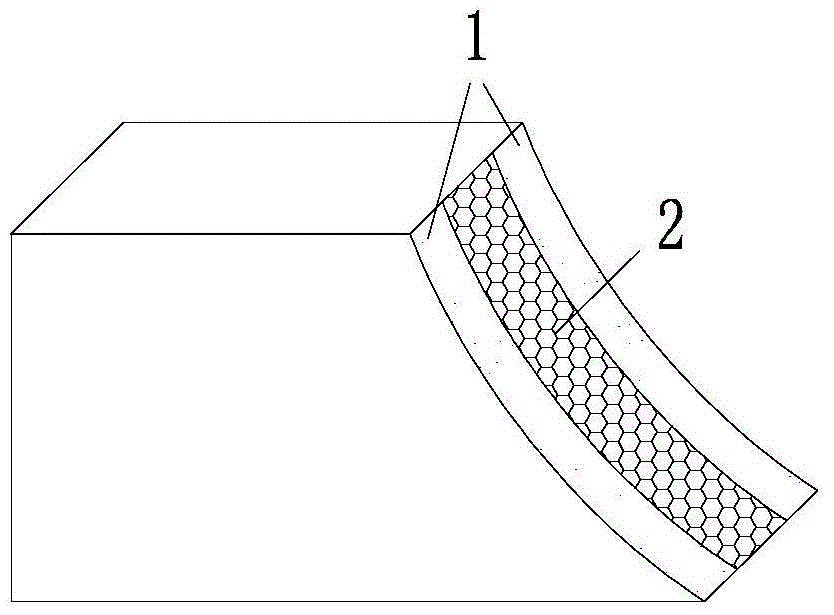

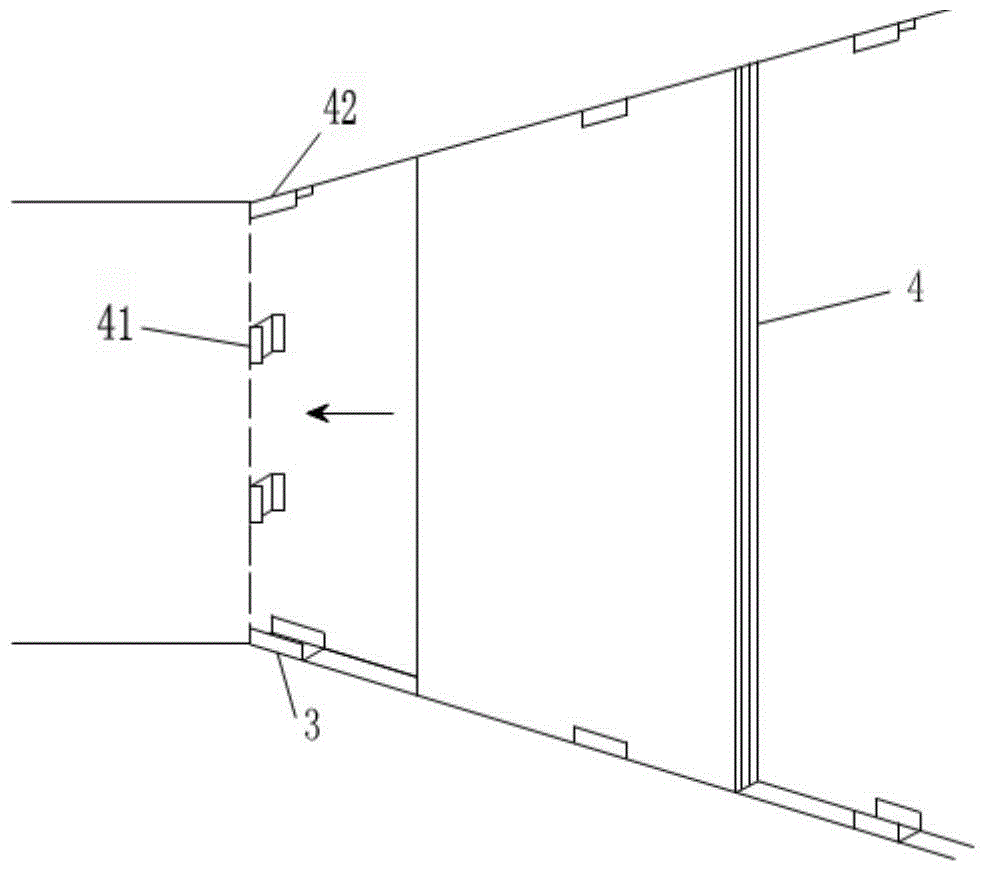

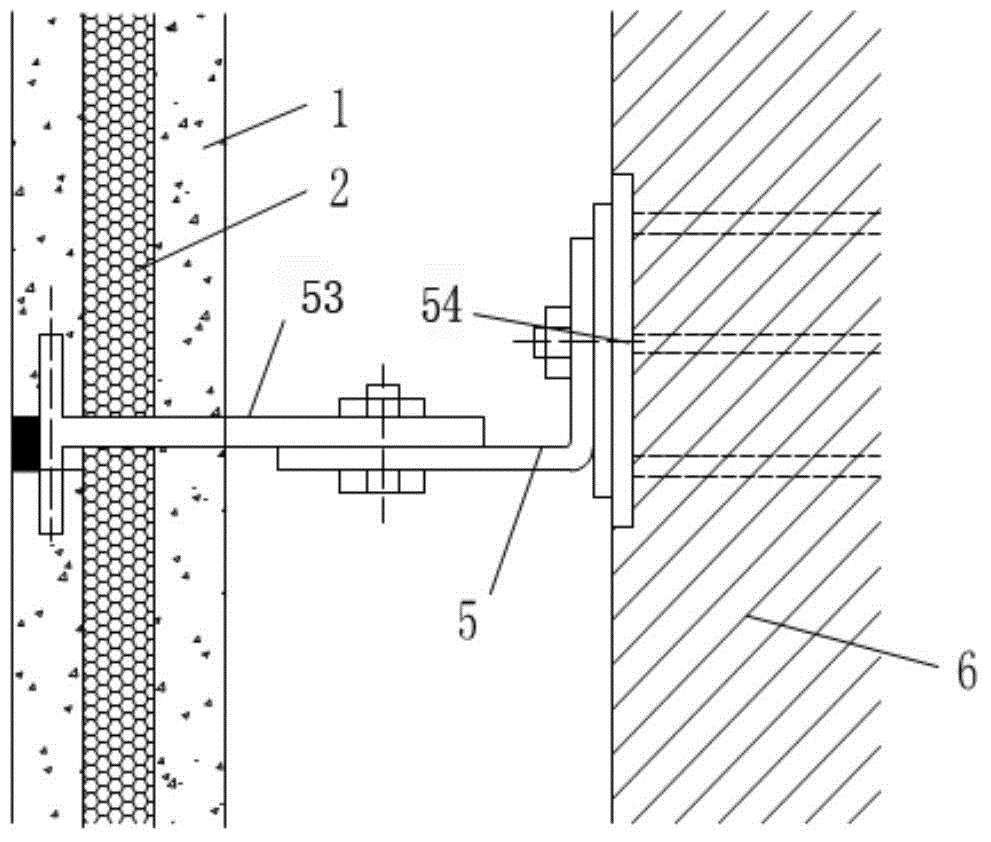

[0024] The wall is formed by splicing wallboards; refer to figure 1 , the wallboard is a sandwich structure, using a plate made of ultra-high toughness cement-based composite material as the side panels 1, and filling the heat insulation and sound insulation materials between the side panels 1 to form a sandwich layer 2;

[0025] The mass ratio of the components of the mortar matrix of the ultra-high toughness cement-based composite material is cement: water: fine aggregate: fly ash: silica fume: granulated blast furnace slag: metakaolin = 1: (0.27~2.2): (0~ 3): (0~6.9): (0~0.3): (0~0.55): (0~0.4), where the maximum particle size of fine aggregate is not greater than 0.55mm, fly ash, silica fume, granulated blast furnace The weight of slag and metakaolin is not zero at the same time. In addition, chopped fibers are added to the mortar mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com