A kind of ultra-high performance concrete anti-slip ramp

An ultra-high-performance, concrete technology, applied in the field of floor materials, can solve the problems of slope aesthetics, poor durability, easy to fall off, etc., which affect driving comfort, to ensure driving comfort and aesthetics, impact resistance and durability. Good performance and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

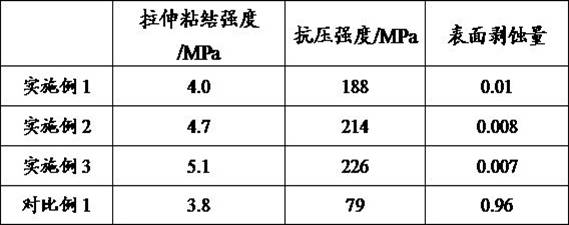

Examples

Embodiment 1

[0027] A concrete compacting enhancer, which is prepared by mixing and stirring the following components in weight percent: Portland cement 30.0%, aluminate cement 5.0%, primary fly ash 4.0%, diatomite 10.0%, garnet 39.4% of sand, 6.3% of copper-plated steel fiber, 0.8% of polycarboxylate superplasticizer, 4.0% of inorganic pigment, 0.3% of lithium carbonate, 0.2% of calcium chloride, and the ratio of water to material is 0.1:1.0. Invention of ultra-high performance concrete anti-slip ramps.

Embodiment 2

[0029] A concrete compacting enhancer, which is prepared by mixing and stirring the following components in weight percent: Portland cement 27.0%, aluminate cement 8.0%, slag powder 4.0%, diatomite 8.0%, garnet sand 41.7% , 8.3% of copper-plated steel fiber, 0.7% of polycarboxylate superplasticizer, 2.0% of inorganic pigment, 0.2% of sodium sulfate, and 0.1% of lithium sulfate. The ratio of water to material is 0.1:1.0. Add water and stir evenly to obtain the super high performance of the present invention Concrete skid ramp.

Embodiment 3

[0031] Portland cement 24%, sulfoaluminate cement 6.0%, aluminate cement 5.0%, diatomaceous earth 10.0%, garnet sand 44.0%, copper-plated steel fiber 7.3%, polycarboxylate superplasticizer 0.6%, Inorganic pigment 3.0%, lithium carbonate 0.1%, water-material ratio of 0.1:1.0, add water and stir evenly to prepare the ultra-high performance concrete anti-slip ramp of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com