A kind of water-based environmental protection sealing paste

A sealing paste and environmental protection technology, applied in the field of water-based environmental protection sealing paste and its production process, can solve the problems of leakage, poor quality of prefabricated buildings, good elasticity and elastic recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A water-based environmental protection sealant:

[0027] Raw material name parts by mass Raw material name parts by mass latex 42 calcium carbonate 14 plasticizer 12 Ammonium polyphosphate 5 Nano functional filler 0 fungicide 0.5 Infiltration crystal masterbatch 3 Dispersant 0.6 glass flakes 3 D 0.3 Bentonite Microspheres 8 Deionized water 11.6

Embodiment 2

[0029] Raw material name parts by mass Raw material name parts by mass latex 42 Barium sulfate 14 plasticizer 12 flame retardant 5 Nano functional filler 0.1 fungicide 0.5 Infiltration crystal masterbatch 4 Dispersant 0.6 glass flakes 6 D 0.3 Bentonite Microspheres 8 Deionized water 7.5

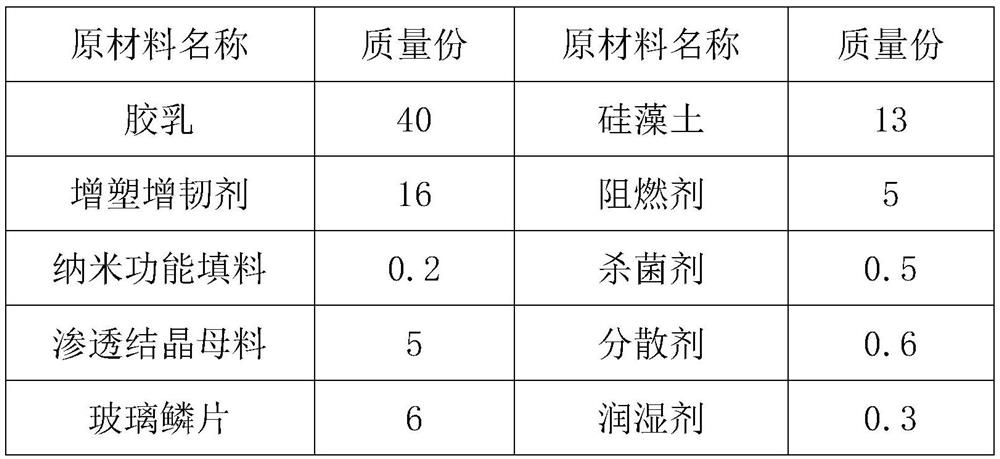

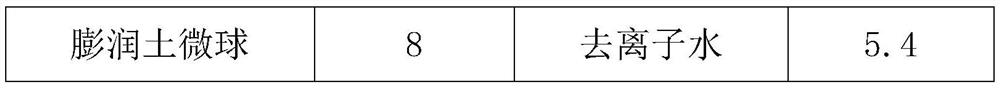

Embodiment 3

[0031] Raw material name parts by mass Raw material name parts by mass latex 40 diatomite 14 plasticizer 14 flame retardant 5 Nano functional filler 0.1 fungicide 0.5 Infiltration crystal masterbatch 4 Dispersant 0.6 glass flakes 6 D 0.3 Bentonite Microspheres 8 Deionized water 7.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com