Turbofan-type double-blade horizontal axis axial torque balance wind turbine generator

A generator and horizontal shaft technology, applied in the field of wind power generators, to achieve the effect of reducing driving resistance, reducing the transmission process, and increasing relative speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

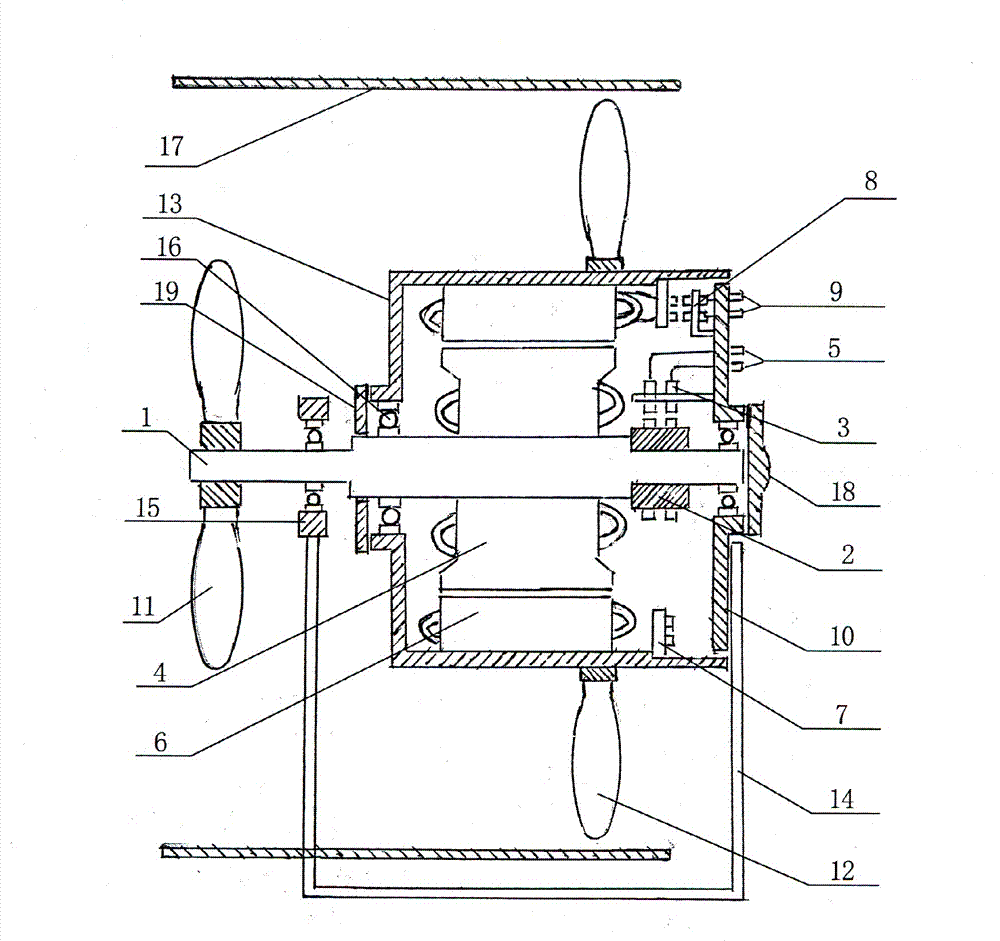

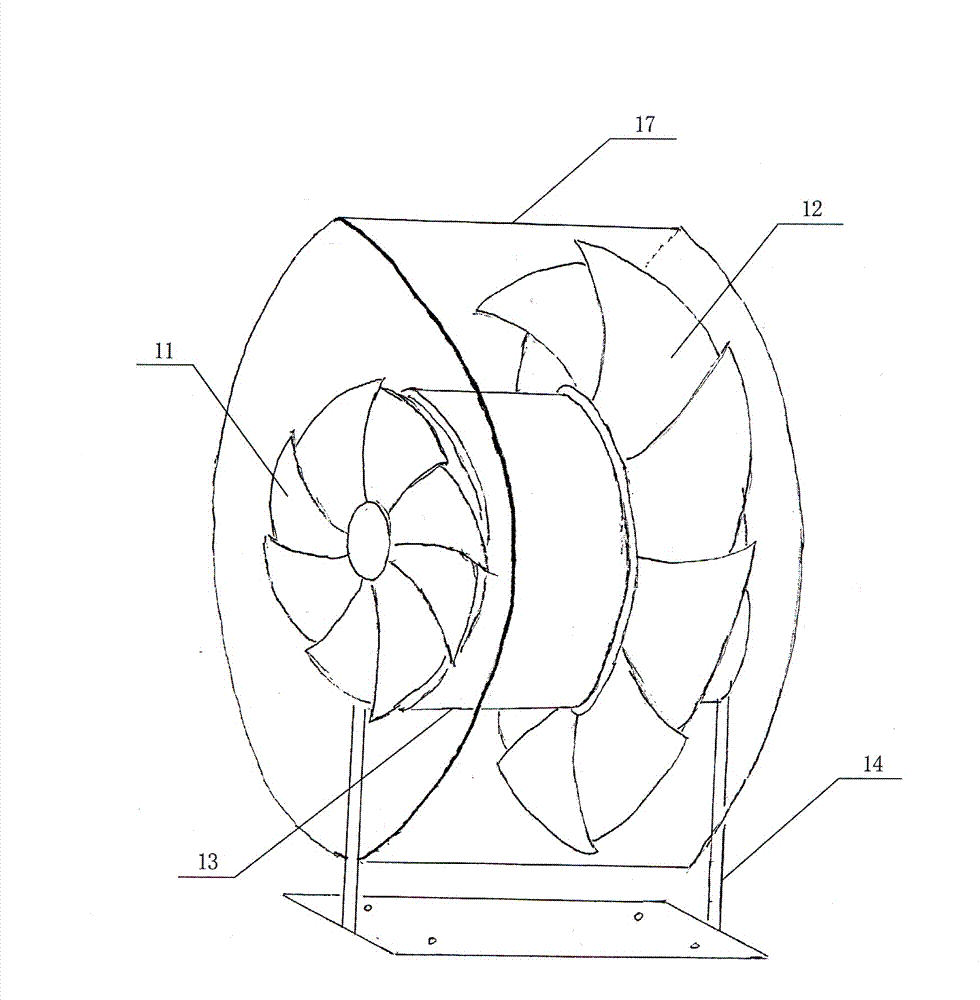

[0027] as attached figure 1 The illustrated embodiment is a turbofan double-blade horizontal axis axial torque balance wind power generator, including a main shaft 1, an armature collector ring 2, an inner rotor armature coil 4, an inner rotor impeller set 11, a generator The fixed end cover 10, the connecting bearing 15 of the inner rotor of the generator, are installed on the frame 14; the excitation coil 6, the exciting conductive slip ring 7, the outer rotor impeller group 12, and the outer rotor housing 13 of the generator are connected to the bearing through the outer rotor of the generator 16 is installed on the main shaft 1; armature brush holder 3, armature terminal 5, excitation brush holder 8, and excitation terminal 9 are installed on the fixed end cover 10 of the generator through an insulating device; excitation conductive slip ring 7. Installed on the outer rotor casing 13 of the generator through an insulating device; the air collector 17 is installed on the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com