Friction damper

A friction damper and damper technology, applied in the field of shock, vibration, and earthquake control devices, can solve the problems of unstable damping performance, difficult assembly, limited displacement, etc., and achieve high stress and strain levels, high material utilization, and The effect of large preload displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

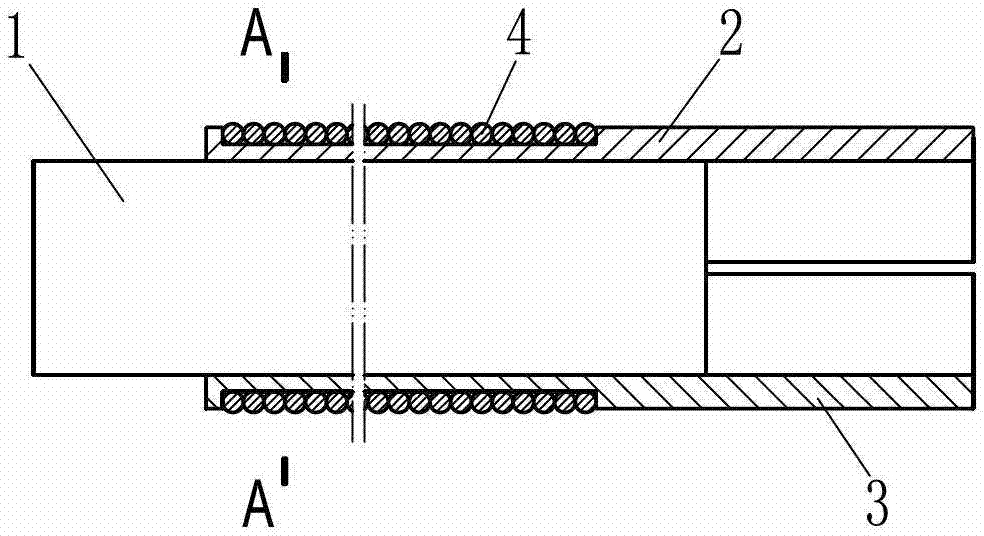

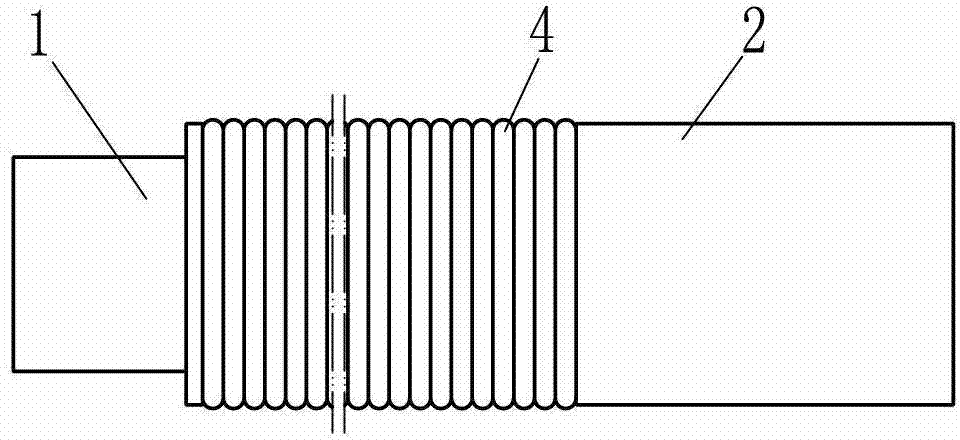

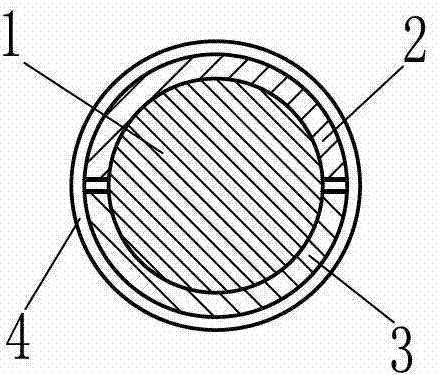

[0091] Such as figure 1 , figure 2 and image 3 The friction damper of the present invention shown includes a plunger 1 and a restraint cylinder, the restraint cylinder is composed of a sub-constraint cylinder 2 and a sub-constraint cylinder 3 along the axial direction of the plunger, and the plunger 1 is in close contact with the inner walls of the sub-constraint cylinders 2 and 3 , the outer surface of the restraint cylinder is provided with a tightening device, specifically the tightening device is a pre-tightening wire rope 4 partially wound on the outer surface of the sub-constraint cylinders 2 and 3, and the pre-tightening wire rope 4 is specifically a steel wire. It should be pointed out that the steel wire 4 The pre-tightening force is applied during the winding process of the surface of the restraining cylinder, and the pre-tightening force is maintained by the end fixing device of the steel wire (usually clamped with screws, not shown in the figure), so the steel w...

Embodiment 2

[0098] Such as Figure 5 , Figure 6 and Figure 7 The difference between the shown friction damper of the present invention and Embodiment 1 is that the limit device includes two limit stops 9 that are respectively fixedly welded on the outer surfaces of the steel sub-constraint cylinders 2 and 3. The tight wire rope is specifically the steel strand 4 wound in the area between the limit stoppers 9. In order to improve the damping force, the steel strand 4 is wound in two layers. In addition, in order to facilitate the connection with the surrounding structures, the plunger and the sub-constraint cylinder are respectively provided with connection interfaces, the connection interface is specifically the connection plate 10 welded on the plunger 1, and the sub-constraint cylinders 2 and 3 are respectively welded and fixed. The connecting plate 11. In addition, in order to prevent the exposed steel strands 4 from rusting during use, a rustproof layer 200 made of polyurethane m...

Embodiment 3

[0106] Such as Figure 5 , Figure 6 and Figure 11 The difference between the shown friction damper of the present invention and Embodiment 2 is that the cross-sectional profile shape of the plunger 1 along its radial direction is a square, and the profile shape surrounded by the inner walls of the sub-constraining cylinders 2 and 3 constituting the constraining cylinder Corresponds to plunger 1 profile.

[0107] It should be pointed out that the plunger in the friction damper of the present invention has a variety of materials, and the cross-sectional profile shape of the plunger in the radial direction can be square, rectangular, circular, triangular, regular pentagonal, regular hexagonal or Rhombus, etc., the shape of the contour surrounded by the inner wall of the sub-constraint cylinder constituting the constraint cylinder corresponds to the contour of the plunger, all of which can achieve good results. Generally, for the convenience of processing, the geometrical sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com