Method for operating tail gas quality flow sensor

A technology of mass flow and sensors, applied in the direction of indirect mass flowmeters, mass flow measurement devices, etc., can solve the problems of distortion of measurement results, deposition, inaccurate determination of exhaust gas mass flow, etc., and achieve the effect of less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

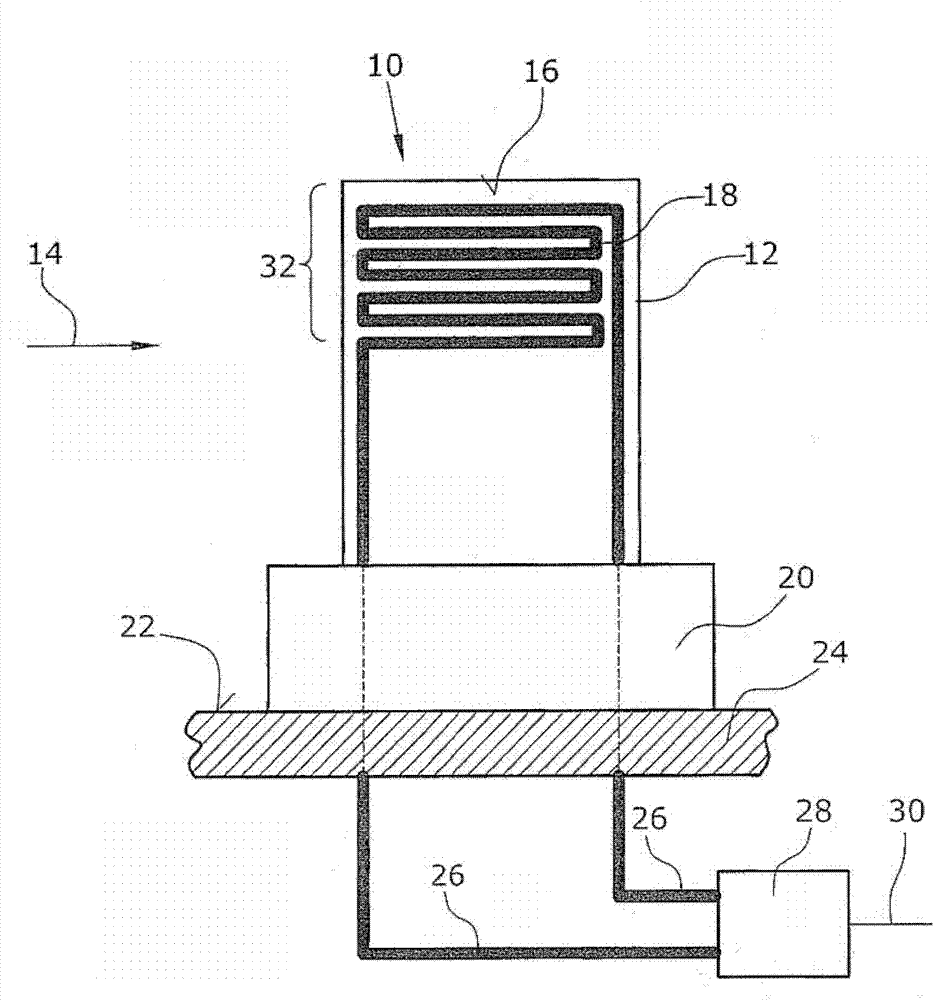

[0019] The exhaust gas mass flow sensor 10 has a substantially square carrier 12 . Said support body 12 , preferably of ceramic, has a width in the range of 2 to 10 mm, a height in the range of 2 to 20 mm, and a thickness in the range of 0.1 to 0.5 mm. In a preferred orientation of the exhaust gas mass flow sensor in the incoming flow, the thickness of the carrier is from the side where the exhaust gas flows. The narrow side of the support body 12 is inflowed by the exhaust gas mass flow in the direction of the arrow 14 . A heating element 18 is provided on the surface 16 of the carrier. The heating element 18 can also be arranged inside the carrier body 12 .

[0020] The carrier body 12 is arranged via a holding element 20 on an inner side 22 of an exhaust gas duct 24 .

[0021] The heating element 18 is connected to a control device 28 via a line 26 . The control device 28 can be connected with the on-board electronic devices and the like through wires 30 . Heating of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com