Large view field projection lithography objective lens

A technology of projected light and large field of view, applied in the field of optics, can solve the problems of increasing the overall volume of the optical system, and achieve the effect of increasing the field of view and controlling the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

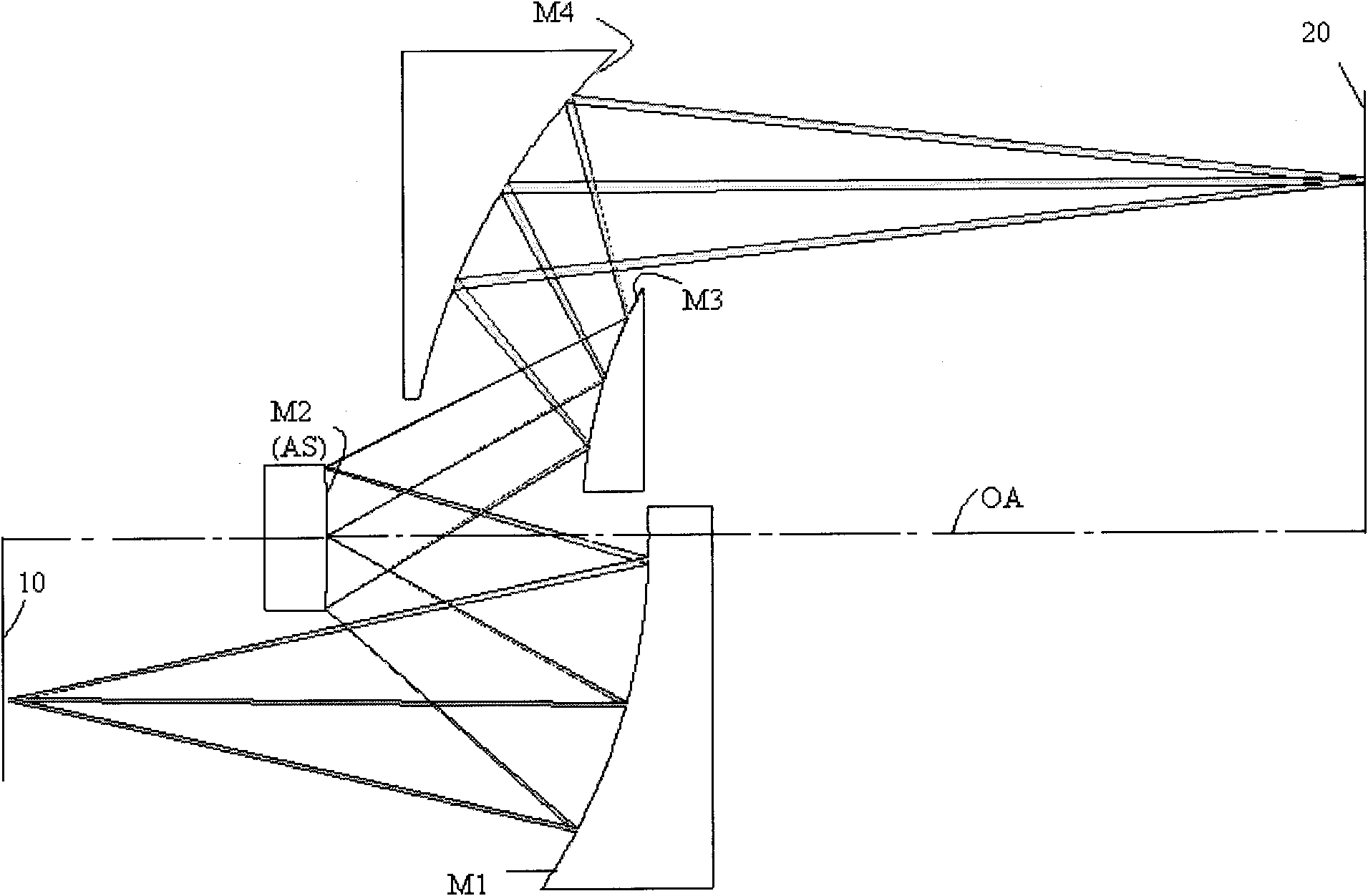

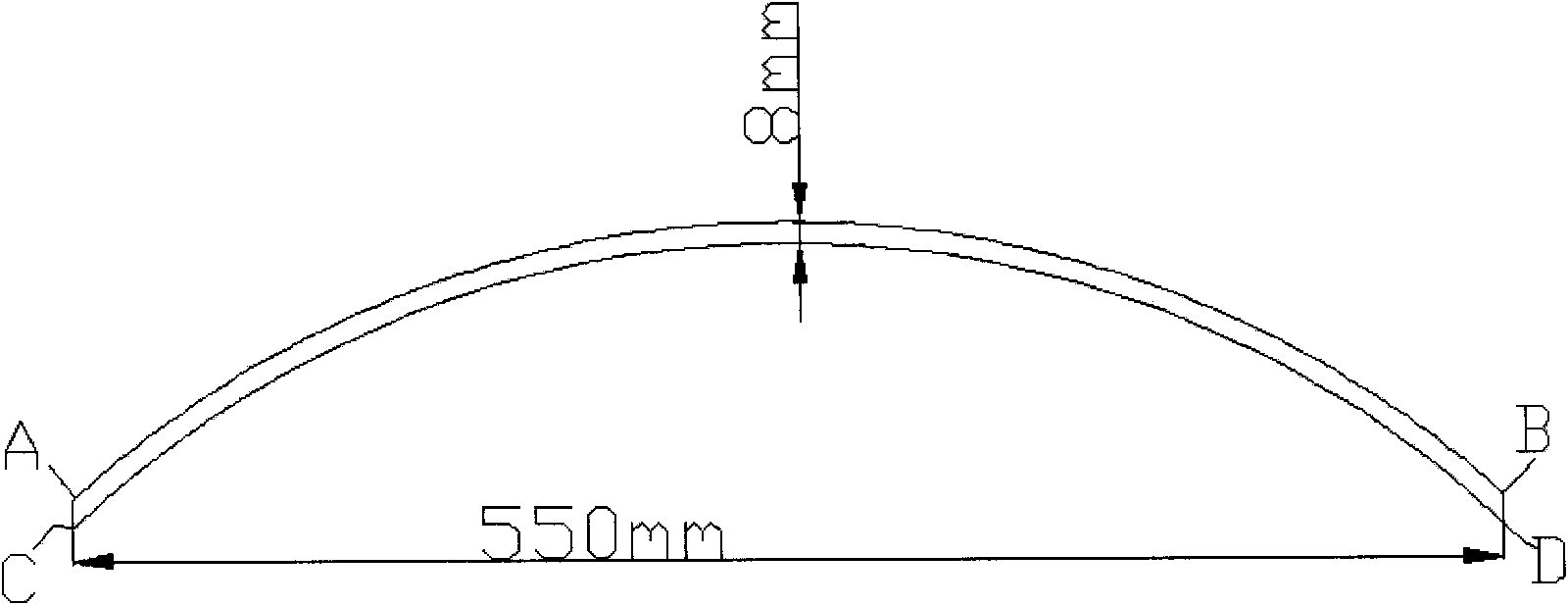

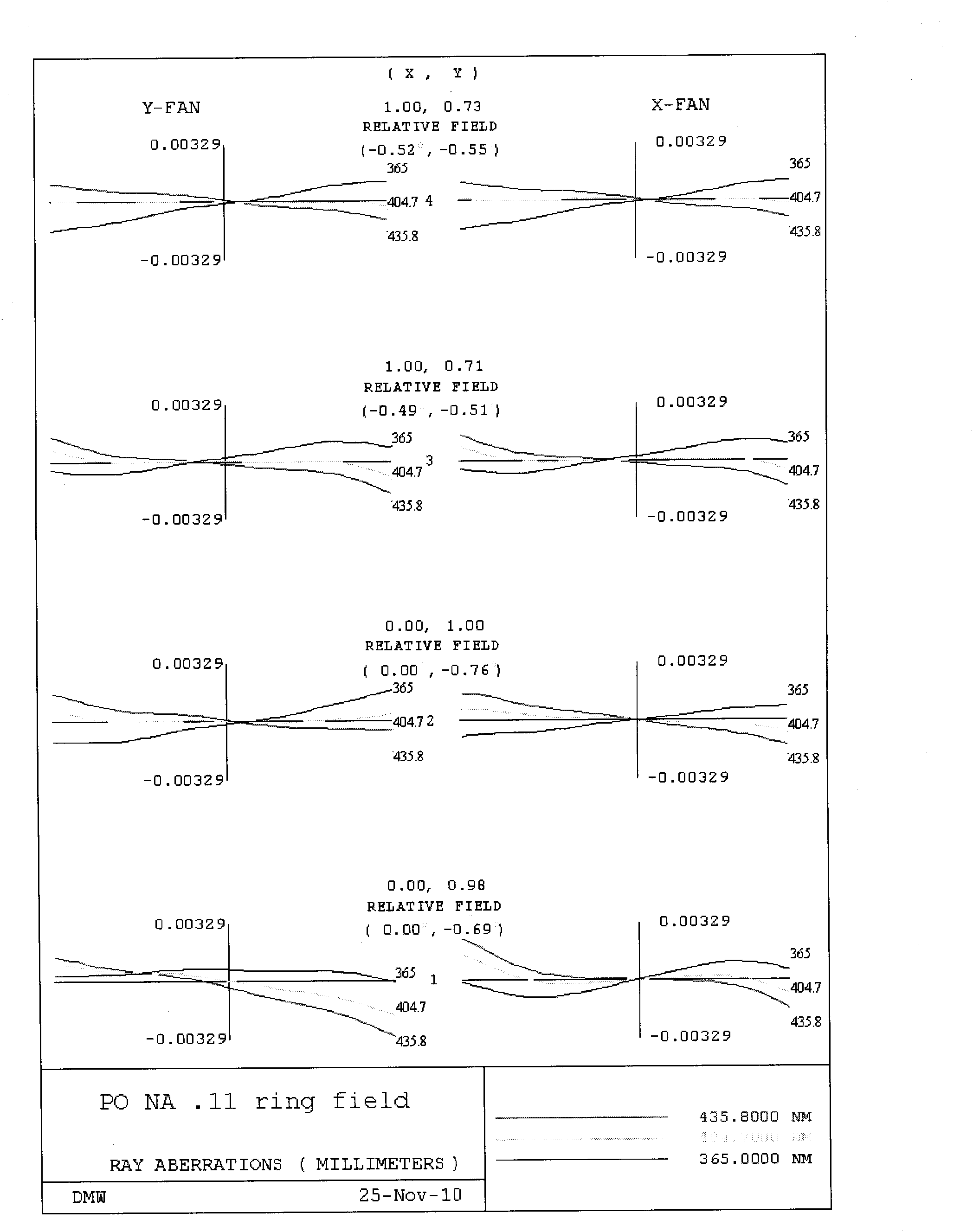

[0022] Such as figure 1 As shown, the projection lithography objective lens of the present invention is made up of 4 reflecting mirrors, and each parameter requirement is as shown in table 1

[0023] Table 1

[0024] Working wavelength

ghi line

Image side numerical aperture NA

0.11

-2

1500mm

[0025] Such as figure 1 As shown, the projection lithography objective lens of the present invention is a purely reflective design consisting of four mirrors. The first reflector M1 is a concave reflector; the second reflector M2 is a convex reflector; the third reflector M3 is a convex reflector; and the fourth reflector M4 is a concave reflector. All four mirrors are located on the same optical axis OA. The aperture stop AS is disposed close to the second mirro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Longitudinal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com