Substrate, liquid crystal display panel and manufacturing method of substrate

A liquid crystal display panel and substrate technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of increased thickness and weight of flat display panels, stress relaxation of chemically tempered glass, damage to panel life, etc., to increase strength and reduce light Loss, improve the effect of anti-collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

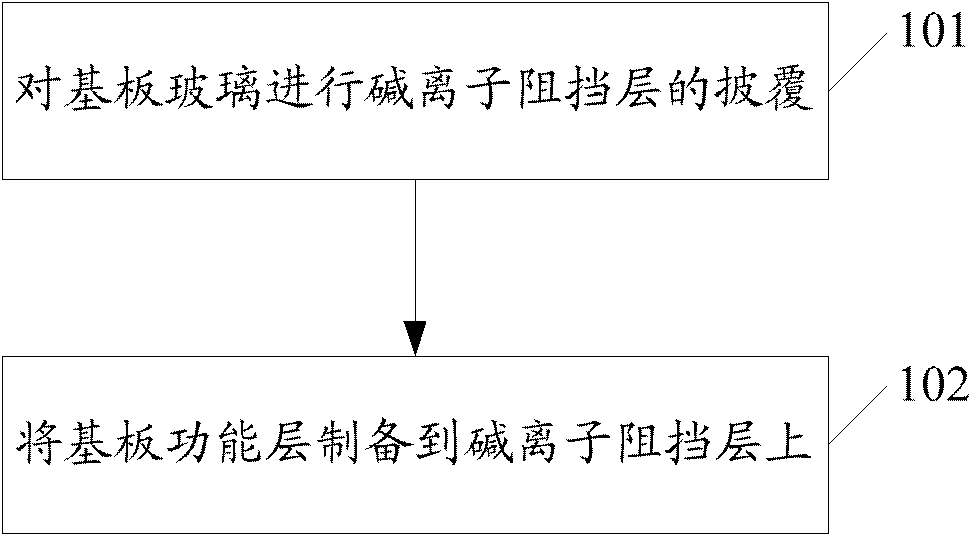

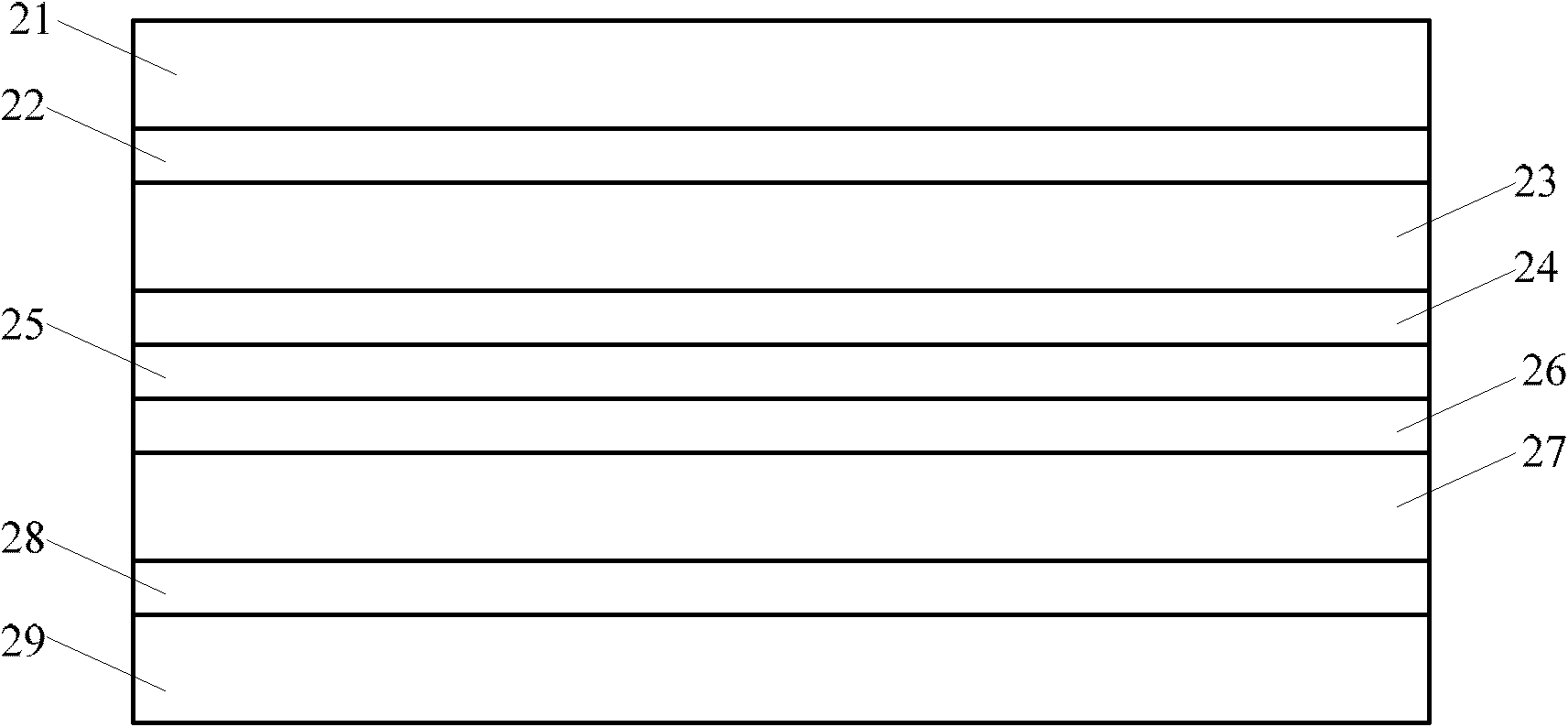

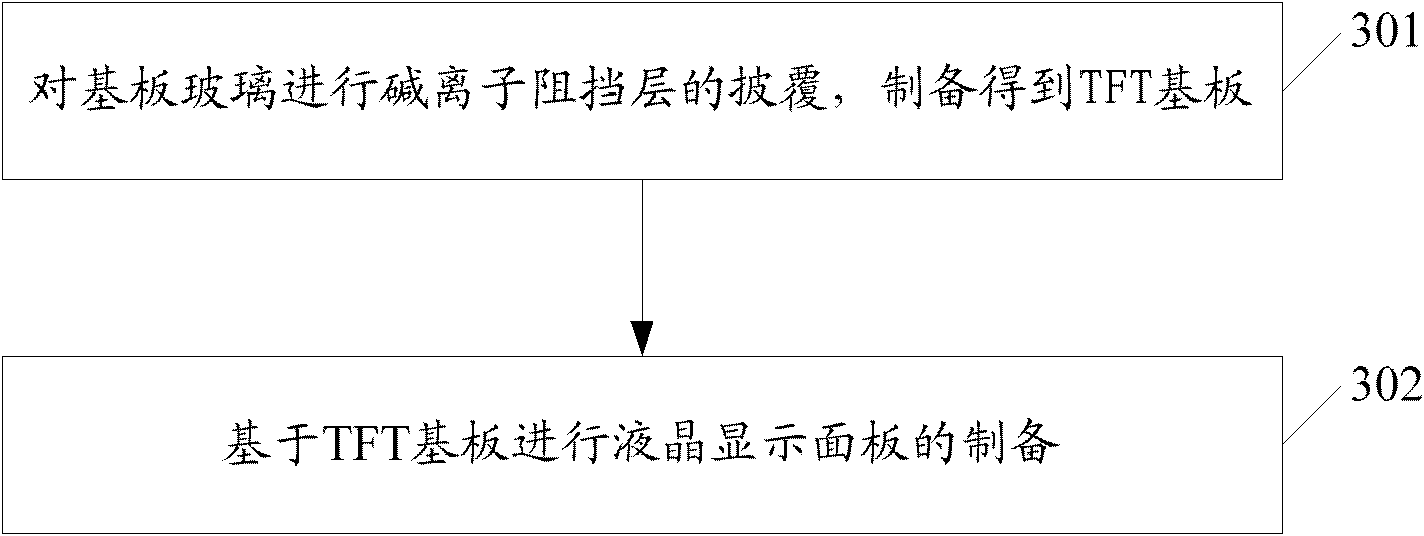

[0054] The basic idea of the present invention is: the substrate includes a substrate glass, an alkali ion blocking layer, and a substrate functional layer; wherein, the alkali ion blocking layer is coated on the substrate glass to block the alkali ions of the substrate glass Diffusion to the functional layer of the substrate; the functional layer of the substrate is prepared on the alkali ion blocking layer.

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail by citing the following embodiments and referring to the accompanying drawings.

[0056]The invention provides a substrate. The substrate includes a substrate glass, an alkali ion blocking layer, and a substrate functional layer; wherein, the alkali ion blocking layer is coated on the substrate glass to block the alkali ion of the substrate glass. Ions diffuse to the functional layer of the substrate; the fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com