Process and plant for cooling acid

A technology for cooling equipment and equipment, applied in lighting and heating equipment, mechanical equipment, sulfur compounds, etc., can solve problems such as damage to tube bundles, damage to pot boilers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

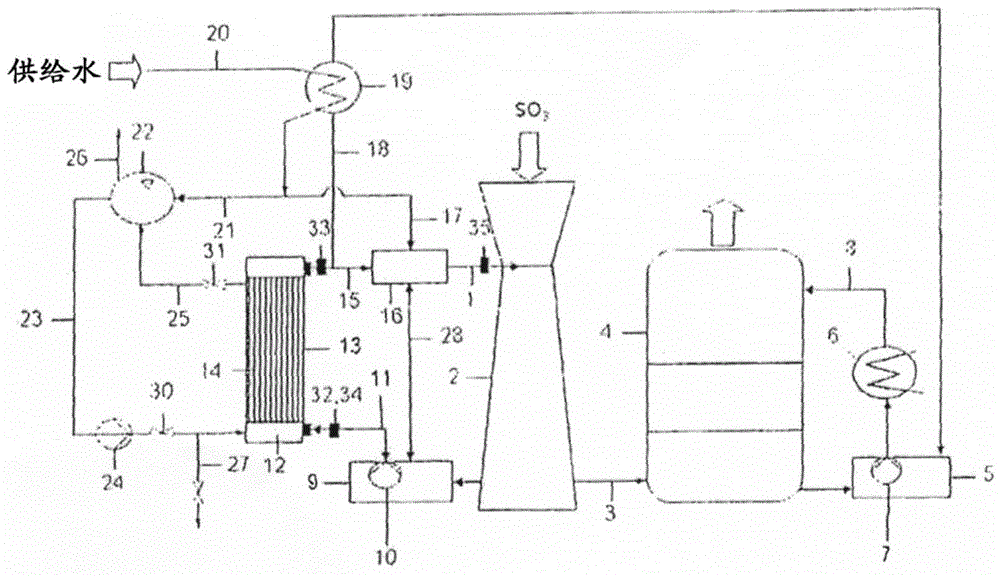

[0027] as from figure 1 The flow chart of the process of the present invention shown in can be seen from the SO 2 converted to SO 3 Gaseous sulfur trioxide from a converter not shown is introduced into the Venturi absorber 2 cocurrently with the concentrated sulfuric acid supplied through conduit 1 and is partially absorbed in the hot acid whose concentration is thereby increased . Via conduit 3, unabsorbed sulfur trioxide is introduced into intermediate absorber 4 where it is passed countercurrently through concentrated sulfuric acid for further absorption. Unabsorbed sulfur trioxide is withdrawn from the top of the intermediate absorber 4 and supplied to a catalytic conversion stage not shown, while enriched sulfuric acid is withdrawn at the bottom, partly removed as product or otherwise used in the plant, After dilution with water in acid pump tank 5 and cooling in heat exchanger 6 , the remaining enriched sulfuric acid is recycled by pump 7 via conduit 8 to intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com