Press roll assembly and spindle combination device of ring die pelletizer with double-direction oil lines

A ring die granulation and combination device technology, which is applied in the direction of mold extrusion granulation, material forming presses, presses, etc., can solve problems such as poor fluidity and dispersion, inability to cool down bearings, and shortened service life of bearings. Achieve good fluidity and dispersion, avoid bearing temperature rise, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

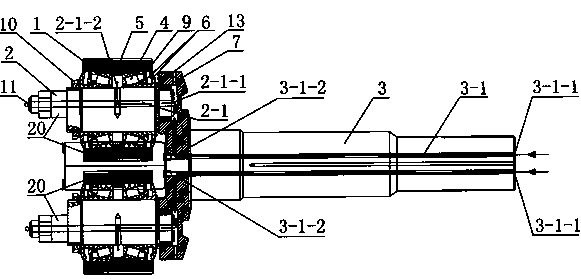

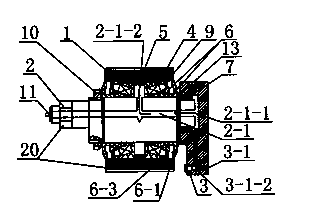

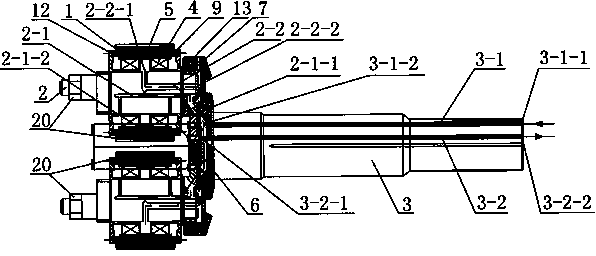

[0027] Such as Figure 3 to Figure 5 As shown, a ring die granulator press roller assembly and main shaft combination device with two-way oil passages includes two press roller assemblies 20 and a main shaft 3 . Each pressing roller assembly 20 includes a pressing roller 1 , an eccentric pressing roller shaft 2 and a pair of bearings 4 , and also includes a washer 13 . The pressing roller 1, the bushing 7 and the washer 13 are all set on the eccentric pressing roller shaft 2. The pressure roller 1 and the eccentric pressure roller shaft 2 are movably connected through a pair of bearings 4 set on the eccentric pressure roller shaft 2, and a retaining ring 5 is arranged between the adjacent end faces of each pair of bearings 4, and the eccentric pressure roller shaft 2 is also set with Seal 6. The seal 6 is the oil deflector ring 6-1 and the oil seal 6-2, both the oil deflector ring 6-1 and the oil seal 6-2 are set on the eccentric roller shaft 2, and the oil deflector ring 6-...

Embodiment 2

[0030] Such as Figure 3 to Figure 5 As shown, a ring die granulator roller assembly and main shaft combination device with two-way oil passage, this embodiment is basically the same as the first embodiment, the difference is that the bearing 4 in this embodiment is a cylindrical roller bearing.

[0031] The self-aligning roller bearing or cylindrical roller bearing selected for bearing 4 in the present invention is selected according to the actual size of the present invention. In addition to the structure described in the above embodiment, the retaining ring 5 in the present invention can also be a separate part, which is not integrated with the eccentric pressure roller shaft 2, but the structural effect of the integral structure of the retaining ring 5 and the eccentric pressure roller shaft 2 better.

[0032] After the liquid engine oil of the present invention flows out through the outlet 3-2-2 of the oil outlet of the main shaft, it can be reused after being cooled and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com