Method for confirming depressurizing distribution of single-rack reversible cold-rolling mill

A technology of cold rolling mill and single stand, which is applied in the direction of rolling mill control device, metal rolling, metal rolling, etc. It can solve the problems of complex structure of objective function and constraint conditions, use of dependence on operators, etc., so as to avoid function processing and realize Easy, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The method for determining the reduction distribution of a single-stand reversing cold rolling mill based on the present invention is applicable to two-roll, four-roll and six-roll single-stand cold rolling mills. This embodiment discloses a method for determining the reduction distribution of a single-stand reversing cold-rolling mill in a process control system of a single-stand six-high reversing cold-rolling mill. The products that can be rolled by this six-high rolling mill include ordinary carbon steel, high-strength steel, some stainless steel and silicon steel, etc. What the present embodiment rolls is medium and high-grade silicon steel, and the machine type is UCM rolling mill.

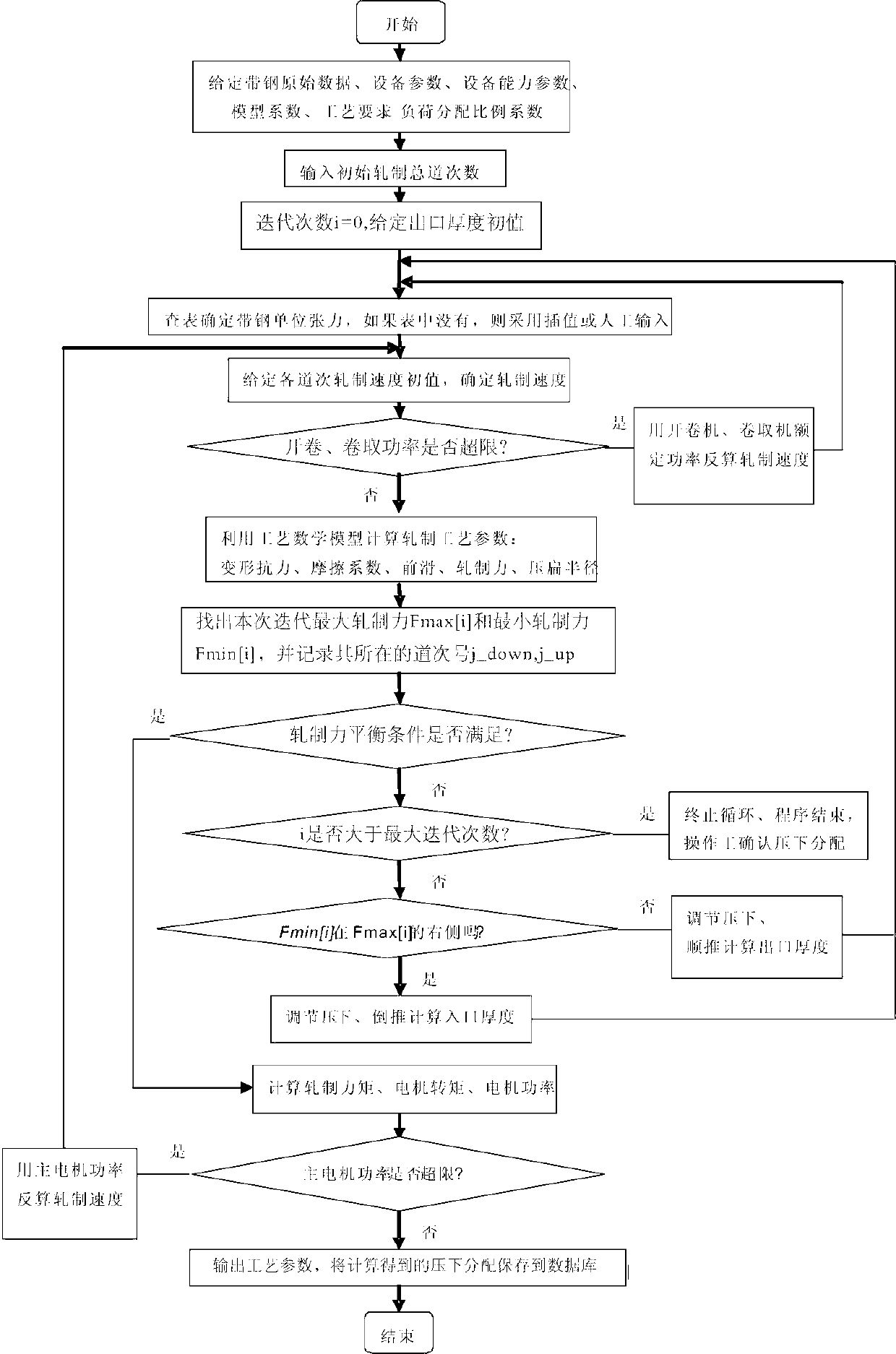

[0043] The method for determining the reduction distribution of a single-stand reversing cold rolling mill provided in this embodiment is as follows: figure 1 shown, including the following steps:

[0044] Step 1. Input strip raw data, equipment parameters, equipment capacity parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com