Three-step aluminum alloy hub producing method and forging dies and spinning dies used by same

A technology for an aluminum alloy wheel hub and a production method, which is applied to metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems that the spinning method cannot be adapted, and achieves less heating process times, good component replacement, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

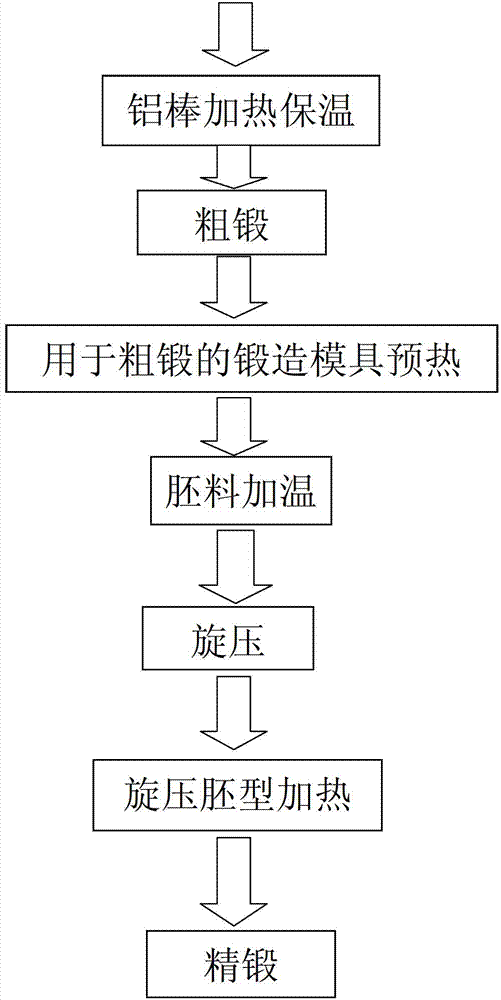

[0033] Example 1, see figure 1 Shown: the preparation of aluminum alloy wheel hub of the present invention adopts three-step aluminum alloy wheel hub production method. Specifically, the method sequentially includes the steps of cutting the aluminum alloy bar stock into blanks, cleaning the blank to remove oil stains, and heating the blank for heat preservation. Wherein, the step of heating and insulating the blank is as follows: heating the blank from room temperature to 450° C. in 20 minutes, and keeping it warm for 2 hours. Aluminum alloy bars can use Φ355mm bars. After that, proceed as follows in sequence:

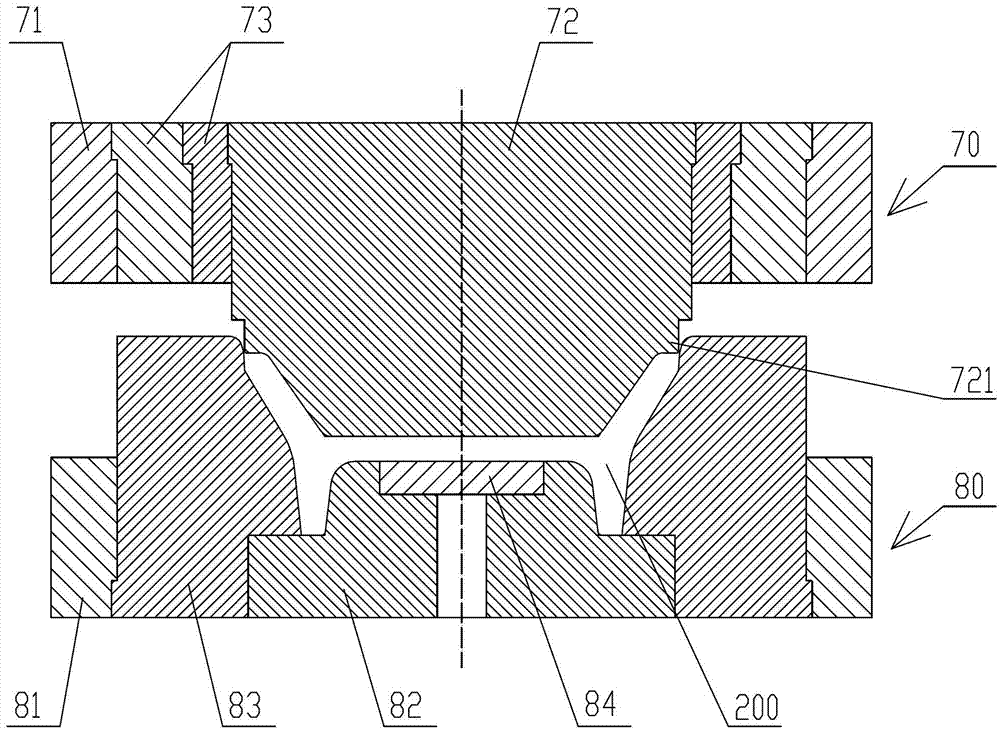

[0034] A) Rough forging blank: Put the blank into the forging mold for rough forging of the press, and upset the blank into a spinning blank. Among them, the press can be a 2500T press.

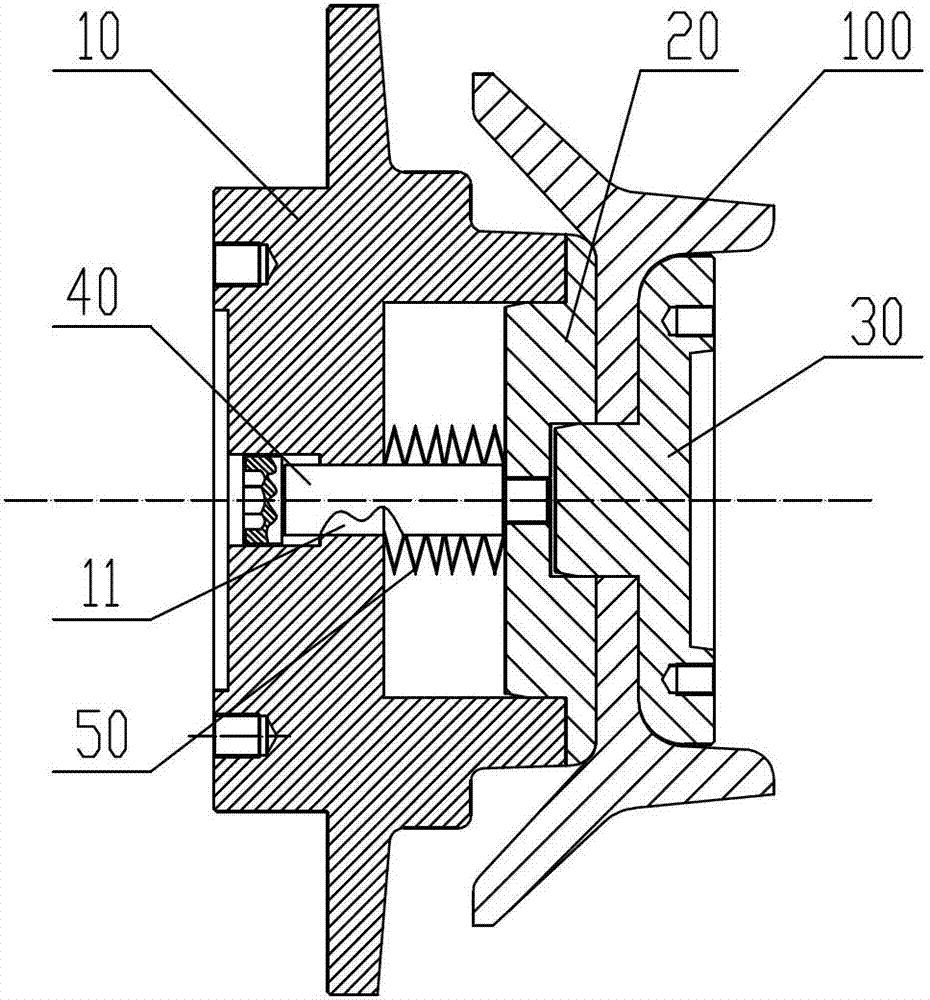

[0035] B) Spinning: Put the spinning blank into the spinning mold on the three-spinner horizontal spinning machine, and spin the spinning blank into a thick wheel hub; among them,...

Embodiment 2

[0043] Example 2: The difference from Implementation 1 is that the step of heating and insulating the blank is as follows: heat the blank from room temperature to 500°C for 25 minutes, and keep it warm for 2.2 hours; Preheat from room temperature to 350°C; in step B), brush No. 38 cylinder oil on the surface of the outer cavity of the spinning die before spinning; in step C), put the rough shape of the hub into the forging for precision forging It takes 23 minutes to heat the rough wheel hub from room temperature to 490°C before entering the mold, and keep it warm for 2.2 hours. Wherein, No. 38 cylinder oil is adopted to replace the water-based release agent, and general graphite oil is not used as the lubricant for spinning, for the same reason that the water-based release agent is used in Example 1.

Embodiment 3

[0044] Example 3: The difference from Implementation 1 is that the step of heating and insulating the blank is as follows: heat the blank from room temperature to 550°C for 30 minutes, and keep it warm for 2.5 hours; in step B), the spinning mold is removed from the spinning mold for 15 minutes before spinning Preheat the room temperature to 380°C; in step B), brush No. 24 cylinder oil on the surface of the outer cavity of the spinning die before spinning; in step C), put the rough shape of the hub into the forging die for precision forging It takes 25 minutes to heat the rough wheel hub from room temperature to 500°C and keep it warm for 2.5 hours. Wherein, the water release agent is replaced with No. 24 cylinder oil, reason is the same as using No. 38 cylinder oil in embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com