Method and device for recovering waste silicon powder from trichlorosilane synthetic furnace

A trichlorosilane, recovery method technology, applied in the direction of silicon halide compounds, silicon, halosilane, etc., can solve the problems of silicon powder splashing to the ground, silicon powder dust, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

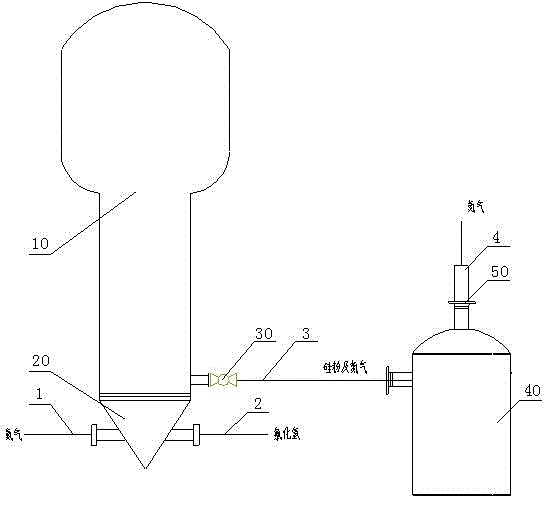

[0017] Such as figure 1 As shown, the waste silicon powder recovery device of the trichlorosilane synthesis furnace described in the embodiment of the present invention includes a synthesis furnace 10 and a silicon powder collection tank 40, and the synthesis furnace 10 communicates with the interface of the silicon powder collection tank 40 through a metal hose 30 , the bottom of the synthesis furnace 10 has a cone structure 20, the two ends of the cone structure 20 are respectively connected with the nitrogen gas inlet pipeline 1 and the normal hydrogen chloride intake pipeline 2, at the top of the cone structure 20 of the synthesis furnace 10 The side wall is provided with a silicon powder discharge valve 30, and the silicon powder discharge valve 30 is connected to the interface on the side wall of the silicon powder collection tank 40 through a metal hose 3, at the nitrogen outlet 4 at the top of the silicon powder collection tank 40 A bag filter 50 is provided.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com