Patents

Literature

51results about How to "Process conditions are easy to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collidal forming process for preparing high strength light ceramic material

The present invention belongs to the field of ceramic material preparing technology, and is especially colloidal state forming process for preparing light high strength ceramic material. The process includes the following steps: preparing suspension with very low solid phase content with special organic monomer, solvent, initiator or chelating agent, and ceramic powder; in-situ solidification through gel polymerization of monomer or high molecular cross-linking to obtain ceramic biscuit; drying, removing binder and no-pressure high temperature sintering to obtain light high strength ceramic material. The present invention can control the porosity and pore size of the ultimate product through altering the solid phase content in the suspension, the sintering condition and the powder size. The present invention has simple technological process, low cost, environment friendship and other advantages, and the produced ceramic material has wide application range.

Owner:TSINGHUA UNIV

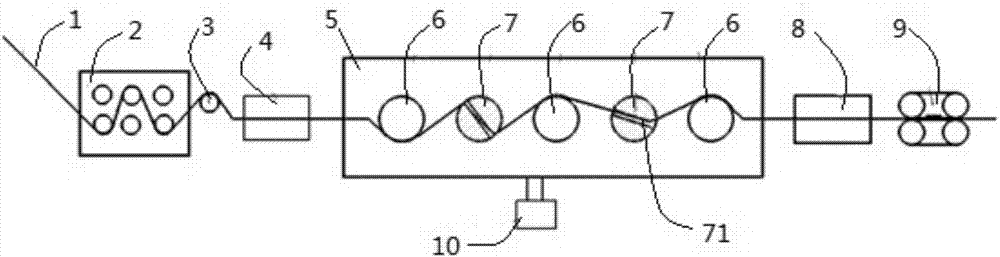

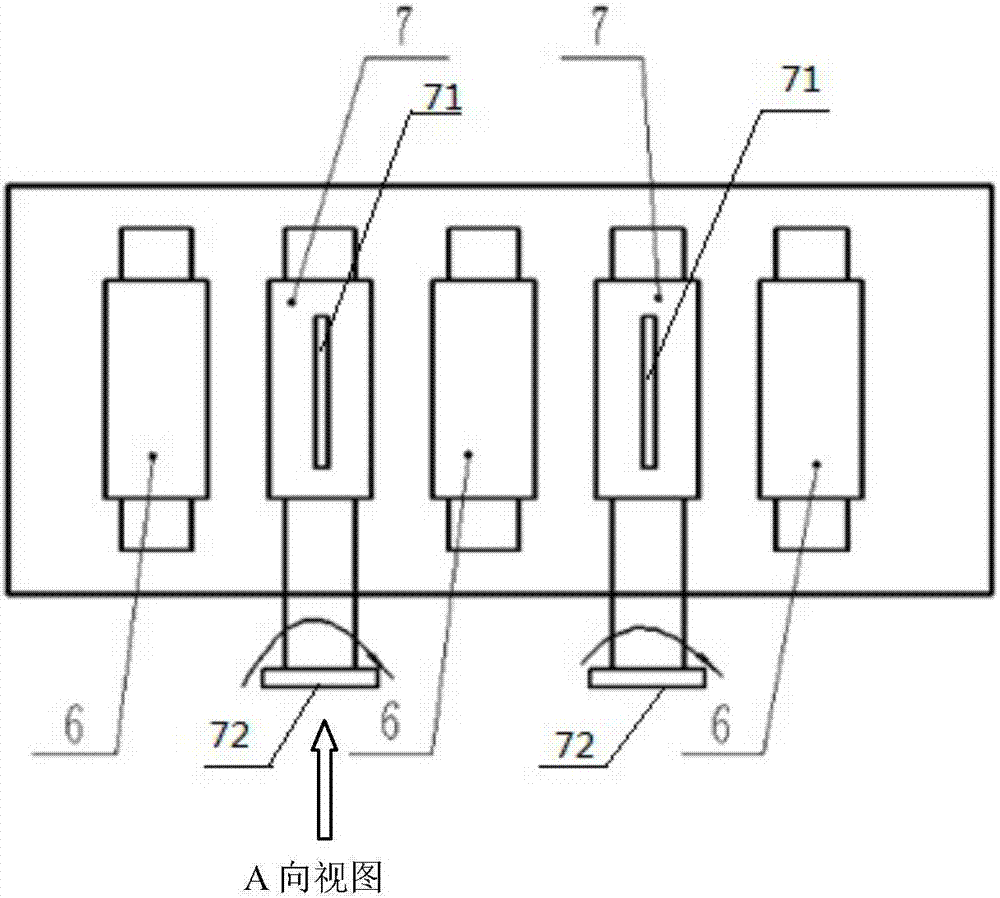

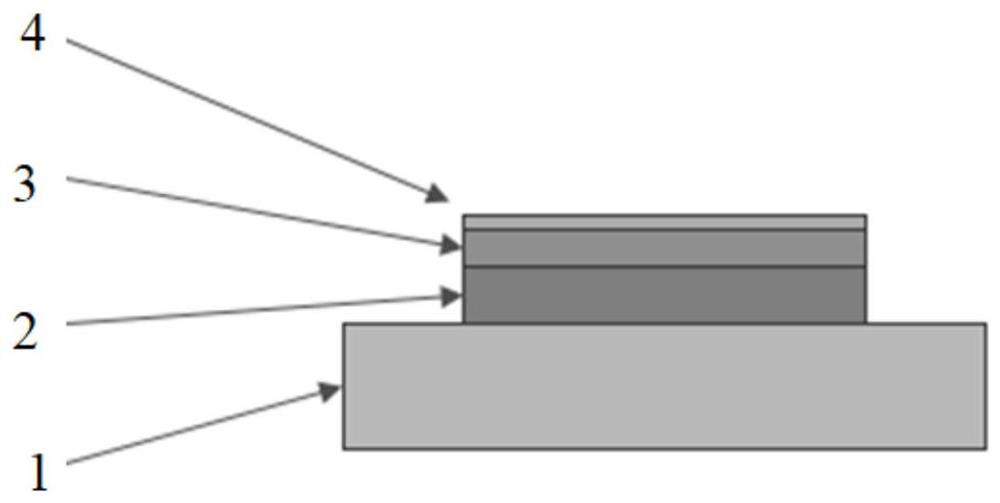

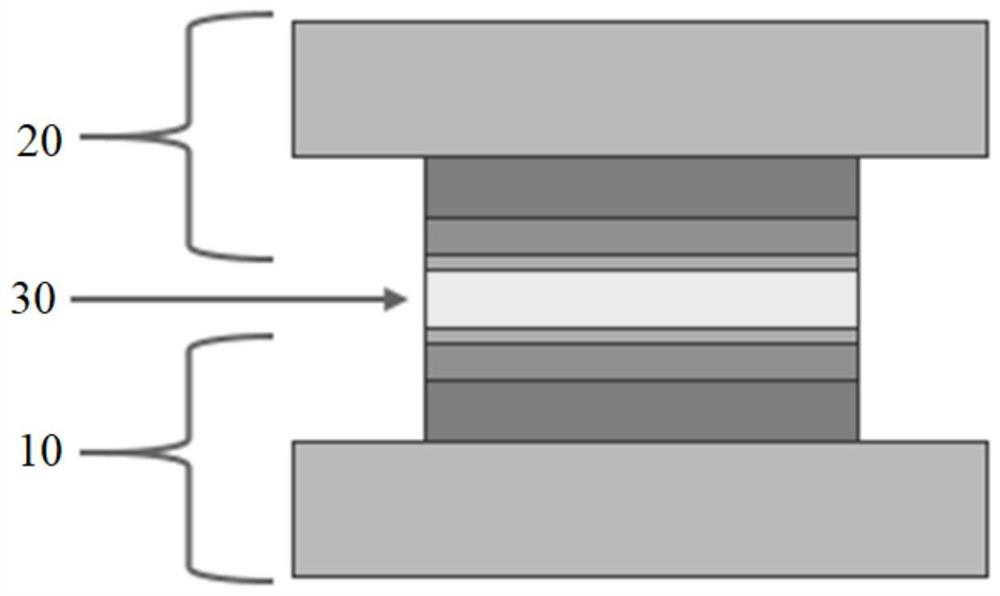

Continuous fiber-reinforced thermoplastic resin melt impregnation device and preparation method

ActiveCN106903906AImprove composite effectIncrease expanded widthFiber bundleThermoplastic composites

The invention discloses a continuous fiber-reinforced thermoplastic resin melt impregnation device and a preparation method. The melt impregnation device comprises a filament spreading frame, a preheating device, a melt impregnation mold, a cooling device, a traction device and an extruder. The melt impregnation mold comprises at least one slit roller which is provided with a slit, and the slit rollers can rotate in an adjusting mode. The melt impregnation device further comprises a plurality of dispersing rollers, and the dispersing rollers and the slit rollers are arranged in a staggered mode at equal intervals. According to the continuous fiber-reinforced thermoplastic resin melt impregnation device and the preparation method provided by the invention, the wrapping angle of a fiber bundle in the melt impregnation mold can be adjusted online, the spreading width of the fiber bundle is increased, the fiber bundle impregnation degree is improved, the continuous fiber-reinforced thermoplastic resin compounding effect is improved, and continuous fiber-reinforced thermoplastic composite prepreg or prepreg tapes are prepared continuously.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for preparing high stone powder mixing quantity porous baked brick

The invention belongs to the field of building material, and relates to a method for preparing a high stone powder mixing quantity porous baked brick which comprises the raw materials by weight percent: 80-95% of stone powder, 3-5% of sintering auxiliary agent and 0-17% of additive. The raw materials are simultaneously added pore for forming a medium with the weight accounting for 3-10% of the total weight of the powder, and the solvent is water solution containing 1-5% of binding agent. The preparation method comprises the steps such as weighing the raw materials, mixing, molding, drying, sintering, cooling and the like. As the organic binding agent and the sintering auxiliary are added, the bonding force among stone powder particles can be enhanced, and the formability and the sinteringperformance of adobe can be improved. By adding the pore for forming the medium, the density of the baked brick can be reduced. The invention has simple technique, low cost, high stone powder demand,energy conservation, environmental protection as well as high strength and low density of the baked brick. The invention can increase the stone powder mixing quantity in the baked brick and simultaneously reduce the density of the baked brick, thus being beneficial to expanding the application field of the baked brick and improving the using performance thereof.

Owner:周立忠 +1

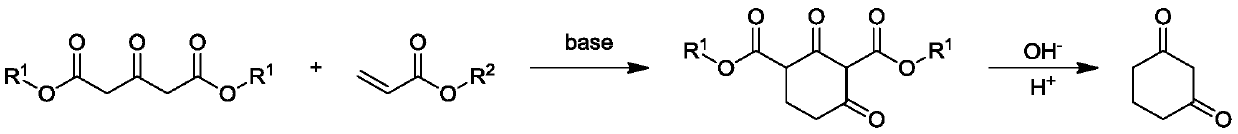

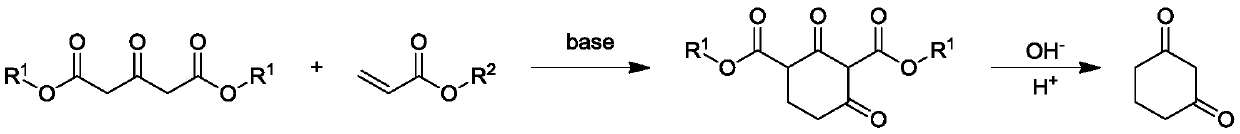

Preparation method of 1,3-cyclohexanedione

ActiveCN111187153AProcess conditions are easy to achieveEasy post-processingOrganic compound preparationCarboxylic acid esters preparationChemical synthesisPtru catalyst

The invention relates to the technical field of chemical synthesis, in particular to a preparation method of 1,3-cyclohexanedione. The preparation method of the 1,3-cyclohexanedione comprises the following steps: with 1,3-acetonedicarboxylic ester and acrylate as raw materials, carrying out condensation and cyclization under the action of a base catalyst to prepare an intermediate; carrying out hydrolysis decarboxylation on the intermediate to obtain a crude product; and recrystallizing the crude product to obtain the 1,3-cyclohexanedione. The preparation method of the 1,3-cyclohexanedione hasthe advantages that process conditions are convenient to realize, post-treatment operation process is simple, yield is as high as 90.9%, reaction selectivity is high, production efficiency is high, operation safety is high, pollution is small, and the preparation method is suitable for industrial scale production.

Owner:山东亘元新材料股份有限公司

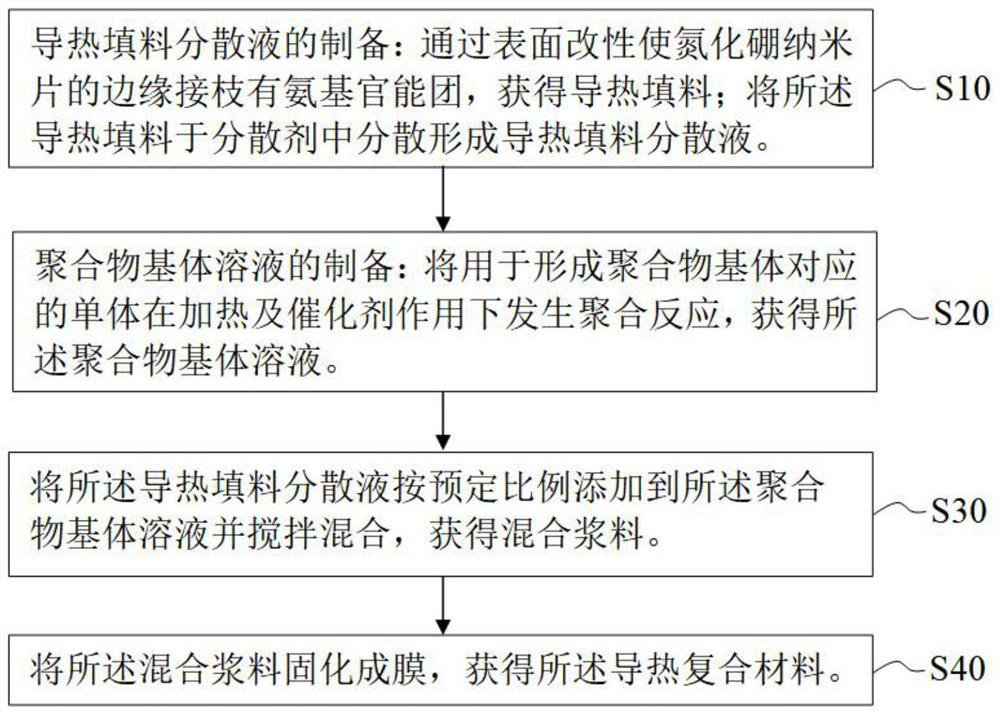

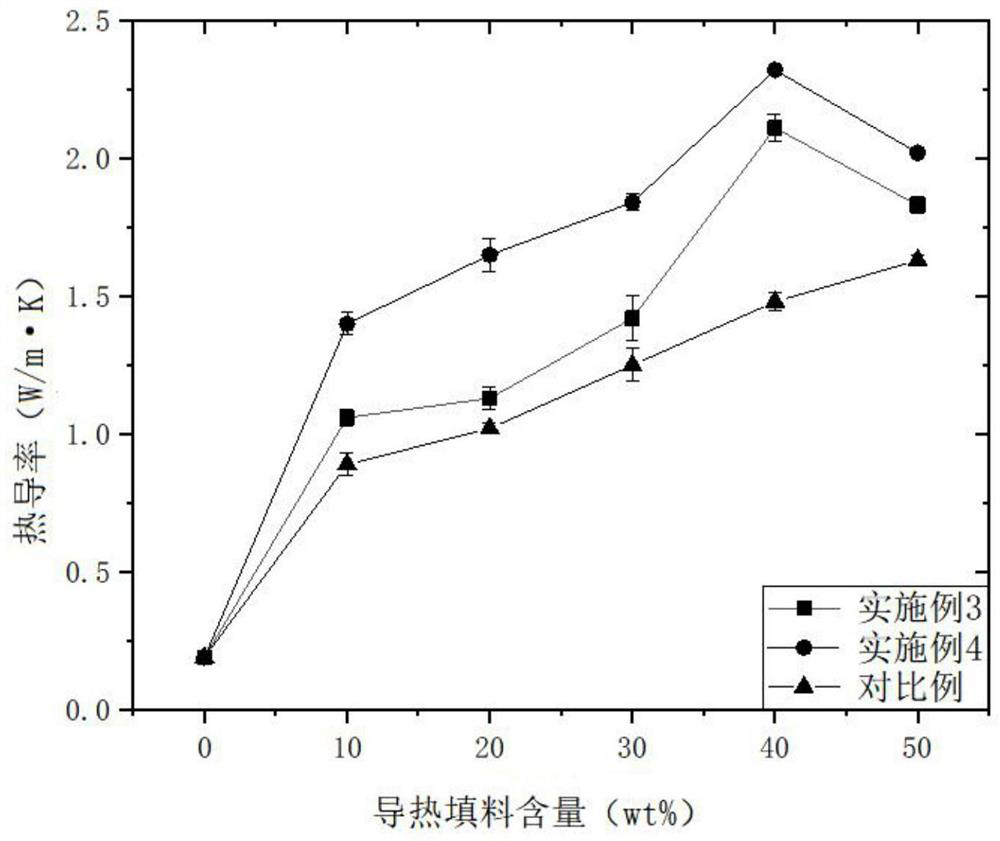

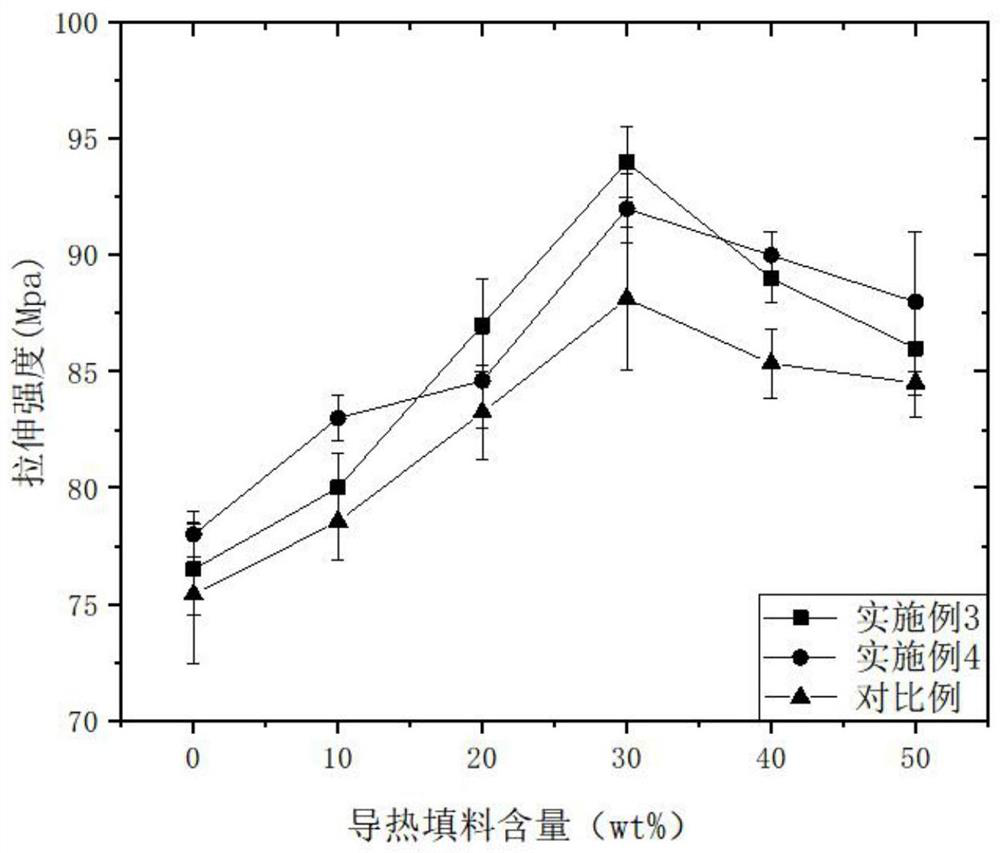

Heat conduction composite material and preparation method thereof

InactiveCN112409791AImprove thermal conductivityImprove wettabilityHeat-exchange elementsPolymer sciencePtru catalyst

The invention provides a heat conduction composite material, which comprises a polymer matrix and a heat conduction filler filled in the polymer matrix, and the heat conduction filler is a boron nitride nano sheet of which the edge is grafted with an amino functional group. The preparation method of the heat conduction composite material comprises the following steps: preparation of a heat conduction filler dispersion liquid: grafting amino functional groups to the edges of boron nitride nano sheets through surface modification to obtain the heat conduction filler; dispersing the heat conduction filler in a dispersing agent to form heat conduction filler dispersion liquid; preparation of a polymer matrix solution: carrying out polymerization reaction on monomers for forming a polymer matrix under the action of heating and a catalyst to obtain a polymer matrix solution; adding the heat conduction filler dispersion liquid into the polymer matrix solution according to a preset proportion,and stirring and mixing to obtain mixed slurry; and curing the mixed slurry to form a film to obtain the heat conduction composite material. The heat conduction composite material provided by the invention has a good heat conduction property and mechanical property.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Preparation method of natural spinnable fiber and okra fiber prepared by the same

InactiveCN1924121ASimple equipment requirementsProcess conditions are easy to achieveBleaching apparatusFibre treatment to obtain bast fibreCelluloseFiber

This invention relates to one method to process fabric fiber by fiber plant stem or plant peel part, which comprises the steps of analyzing, thread out, bleaching, softening and extending, wherein, the bleaching adopts several sections of bleaching as optimization and then for thread process. This invention also relates to one method to extract fabric fiber from Abelmoschus esculentus stem.

Owner:赵子群

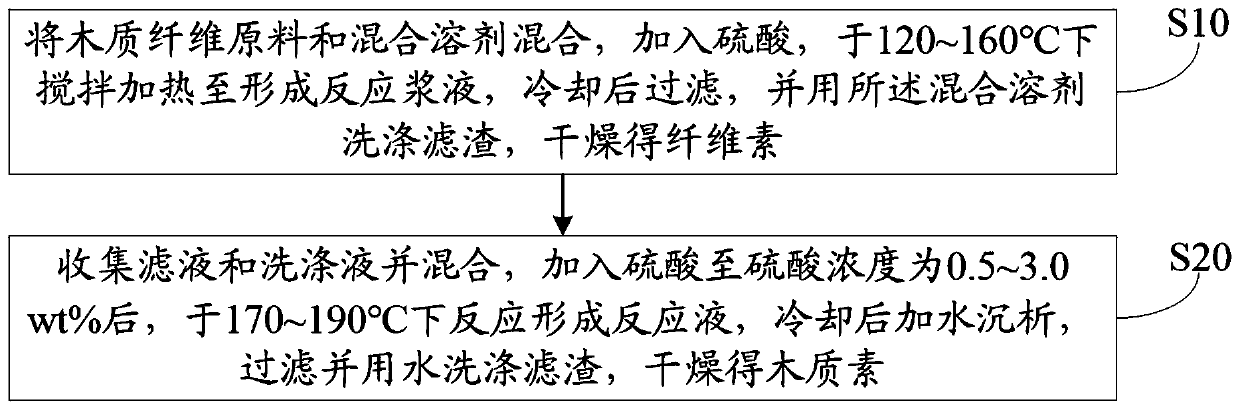

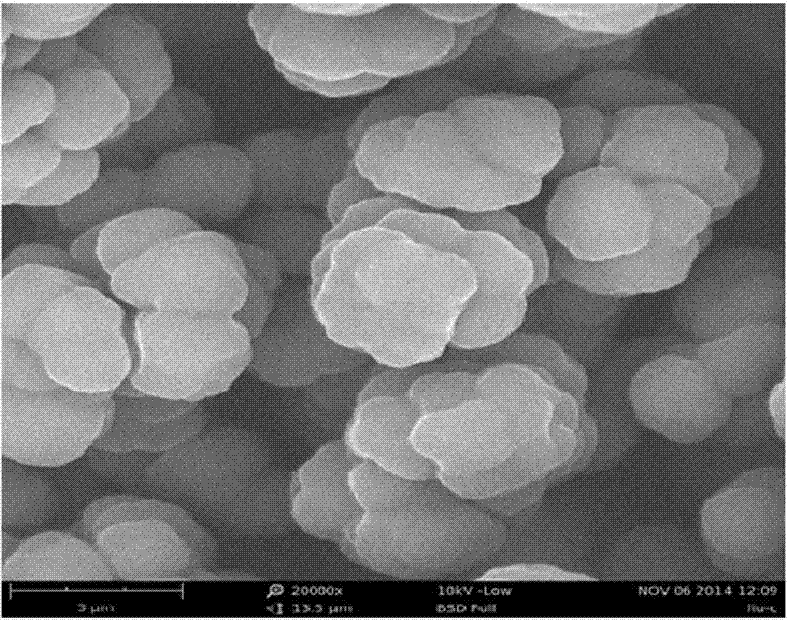

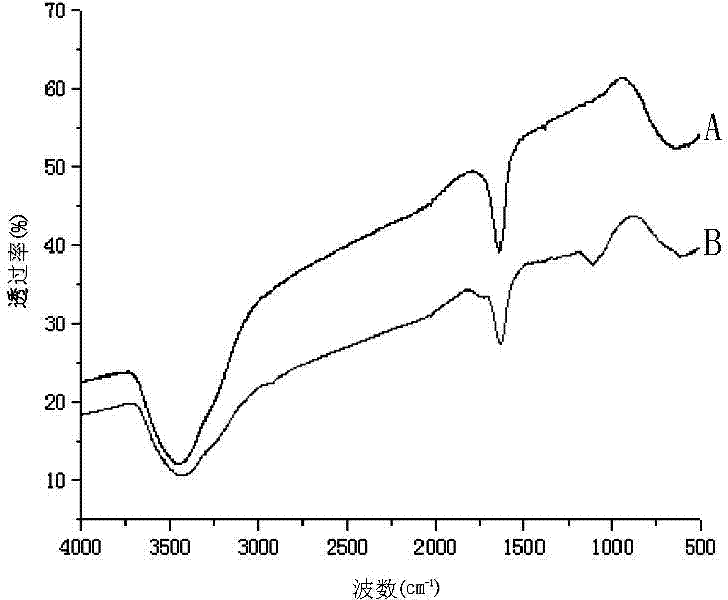

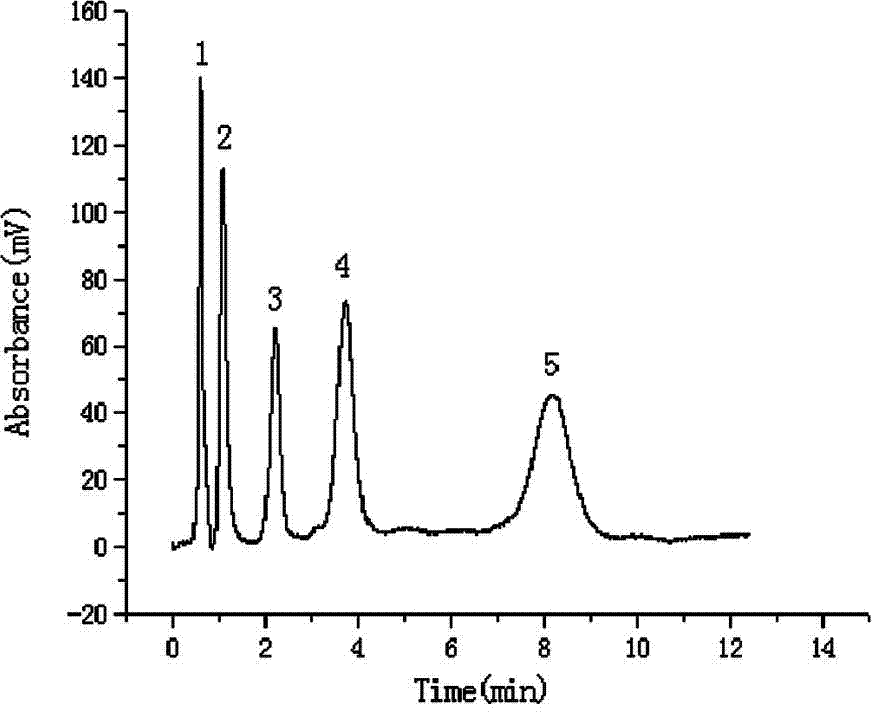

Method for separating lignin and cellulose from lignocellulose raw material

ActiveCN110541320AHigh purityHigh yieldPulping with acid salts/anhydridesLignin derivativesCelluloseOrganic solvent

The invention discloses a method for separating lignin and cellulose from a lignocellulose raw material, and relates to the technical field of high-value utilization of agricultural waste resources. The method for separating the lignin and the cellulose from the lignocellulose raw material includes the following steps: mixing the lignocellulosic raw material and a mixed solvent, adding sulfuric acid, performing stirring and heating at 130-160 DEG C until reaction slurry is formed, performing filtering after cooling, washing the filter residues by using the mixed solvent, and performing dryingto obtain the cellulose; and collecting the filtrate and the washing solution, mixing the collected filtrate and washing solution, adding sulfuric acid, after the concentration of the sulfuric acid is0.5-3.0 wt%, performing a reaction at 170-190 DEG C to form a reaction solution, after cooling, adding water for precipitation, performing filtration, washing the filter residues by using water, andperforming drying to obtain the lignin, wherein the mixed solvent is a mixture of an organic solvent and water. The invention aims to provide the method for separating the cellulose and the lignin, and the method can obtain the cellulose and the lignin with high purity, and improve the yield of the lignin.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Preparation method of inorganic-organic hybrid monolithic column

InactiveCN104492122AUniform skeletonUniform pore sizeOther chemical processesSolid sorbent liquid separationFoaming agentAlcohol

The invention relates to a preparation method of an inorganic-organic hybrid monolithic column. The preparation method comprises the following steps: A. adjusting the pH value of Fe<2+> compound containing aqueous solution, adding with nano-diamond, adding with H2O2 and reacting to obtain hydroxyl nano diamond; B. mixing the hydroxyl nano diamond with KH570, dissolving into ethyl alcohol, carrying out ultrasonic treatment, reacting, centrifuging, washing, and drying to obtain the coupled hydroxylized nano diamond; C. mixing the coupled hydroxylized nano diamond, dipentaerythritolhexaacrylate, a cross-linking agent, an initiator and a pore-foaming agent, injecting the mixture into a stainless steel column, and reacting for 1-1.5h; and D. connecting the stainless steel column with a high-pressure infusion pump, flushing, and drying to obtain the inorganic-organic hybrid monolithic column. The preparation method has simple process, the reaction condition can be realized easily, the operability is good, the prepared monolithic column has uniform framework and pore diameter, has good separation effect and can be used for separating complex samples under a wide-temperature-range condition, and the application field of the monolithic column can be expanded greatly.

Owner:HEBEI UNIVERSITY

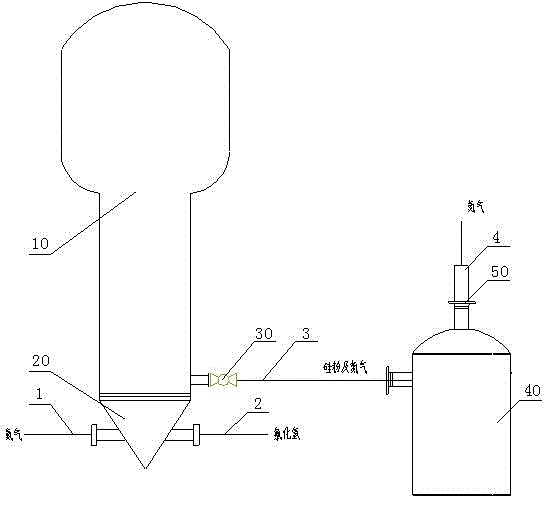

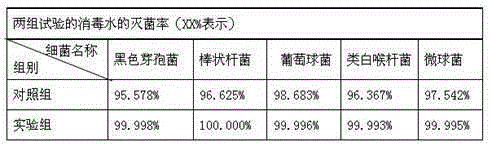

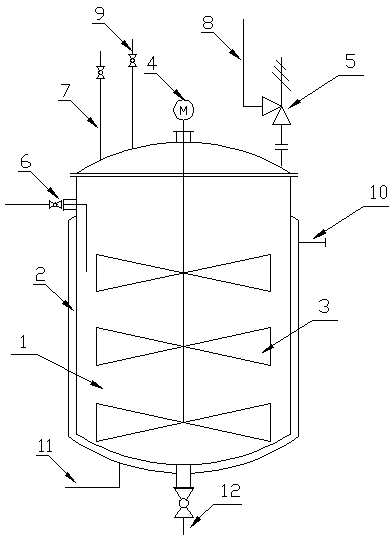

Method and device for recovering waste silicon powder from trichlorosilane synthetic furnace

A method for recovering waste silicon powder from the trichlorosilane synthetic furnace comprises the synthetic furnace and a silicon powder collection tank, and includes steps: A, replacing the synthetic furnace after the synthetic furnace stops normally; B, after replacement is qualified, connecting a silicon powder discharging valve at the bottom of the synthetic furnace with the silicon powder collection tank through a metal hose, and feeding nitrogen into the synthetic furnace through a nitrogen inlet pipeline; and C, turning on the silicon powder discharging valve to enable the silicon powder along with the nitrogen to be brought into the silicon powder collection tank, and emptying the nitrogen through a cloth bag filter at the top of the silicon powder collection tank to enable the silicon powder to be collected into the silicon powder collection tank, so that the silicon powder is fully recycled. The method for recovering waste silicon powder from the trichlorosilane synthetic furnace has the advantages that the method is simple in process, easy in implementation of process conditions and convenient to operate; and waste silicon powder in the synthetic furnace can be fully recycled in reproduction, and dust hazards to personnel bodies during recovery can be avoided. The invention further discloses a device for recovering waste silicon powder from the trichlorosilane synthetic furnace.

Owner:XINTE ENERGY

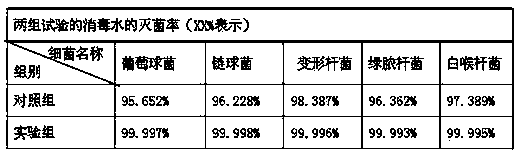

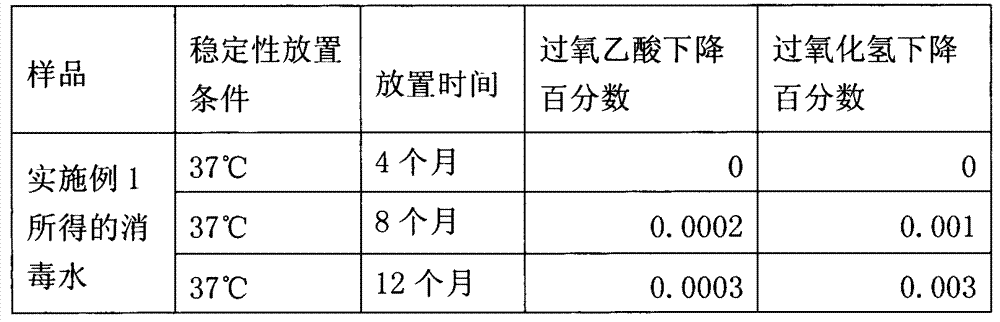

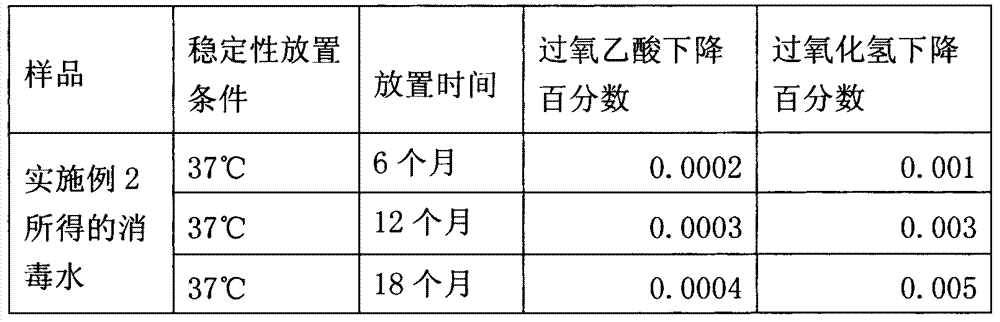

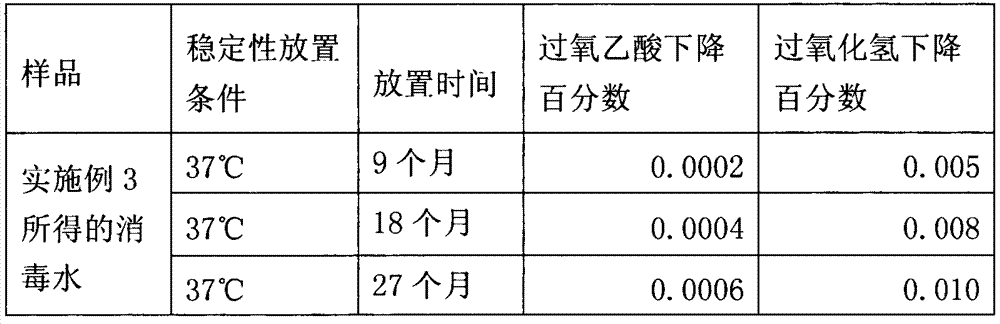

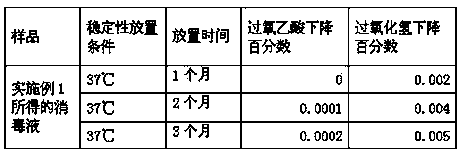

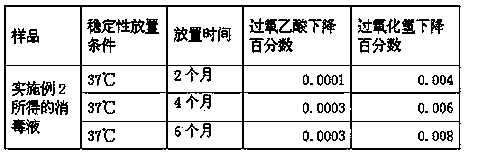

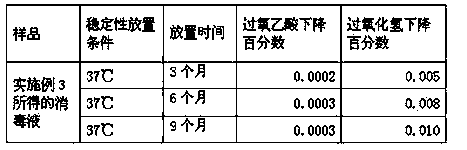

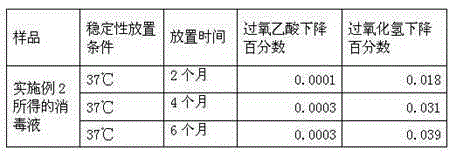

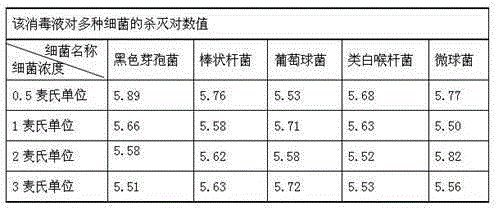

Disinfectant fluid used for washing CT units and preparation method thereof

The invention discloses a disinfectant fluid used for washing CT units. The disinfectant fluid contains the following components by weight percent: 0.5-1.0% of quinoline, 2.0-5.0% of hydrogen peroxide, 0.1-0.5% of peroxyacetic acid, 0.5-1.5% of trichloroisocyanuric acid, 2.0-8.0% of ethanol, 3.0-6.0% of benzalkonium chloride and the balance of water. The disinfectant fluid has the beneficial effects that the production cost of the disinfectant fluid is low; the preparation process is simple; the process conditions are easy to achieve; the product stability is good.

Owner:张光荣

Method for preparing high stone powder mixing quantity baked brick

InactiveCN101672080AIncrease forming plasticity and green brick strengthImprove operabilitySingle unit pavingsClimate change adaptationSolventBuilding material

The invention belongs to the field of building material, and relates to a method for preparing a high stone powder mixing quantity baked brick which comprises the raw materials by weight percent: 80-95% of stone powder, 2-5% of sintering auxiliary agent and 0-18% of additive. The solvent is water solution containing 2%-5% of binding agent. The preparation method comprises the steps of weighing theraw materials, mixing, molding, drying, sintering, cooling and the like. As the organic binding agent and the sintering auxiliary agent are added, the plasticity of the stone powder can be enhanced,and the formability and the sintering performance of adobe can be improved. The invention has the characteristics of simple technique, low cost, high stone powder demand, energy conservation, environmental protection, high strength of the baked brick and the like. The invention not only protects the environment and leads the recycle of the waste stone powder to step in the positive cycle of sustainable development, but also saves the land resources, thus being a useful attempt for replacing clay bricks.

Owner:周立忠 +1

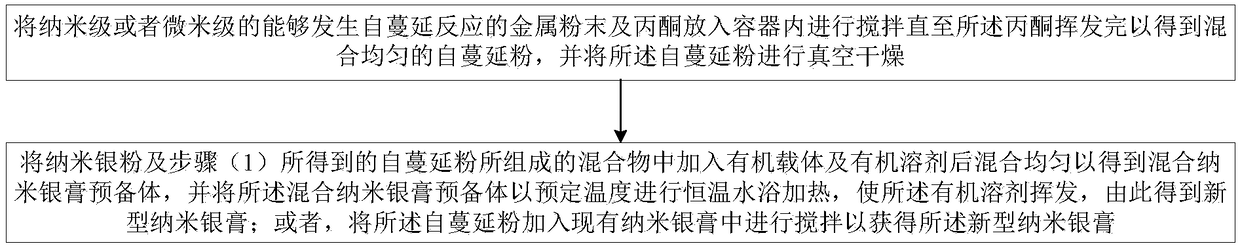

Novel nano silver ointment as well as preparation method and sintering method thereof

ActiveCN108538446AImprove sintering speed and work efficiencyEasy to prepareMaterial nanotechnologyNon-conductive material with dispersed conductive materialMicrometerOrganic solvent

The invention belongs to the technical field of related microelectronic packaging and discloses a preparation method of a nano silver ointment. The method comprises the following steps: (1) pretreating nano-grade or micrometer-grade metallic powder with self-propagating reactions so as to obtain self-propagating powder; (2) uniformly mixing a mixture of nano silver powder and the self-propagatingpowder obtained in the step (1) with an organic carrier and an organic solvent so as to obtain a mixed nano silver ointment preparation, carrying out constant-temperature water bath heating on the mixed nano silver ointment preparation at a preset temperature, and volatizing the organic solvent, thereby obtaining the novel nano silver ointment, or stirring the self-propagating powder with a conventional nano silver ointment, thereby obtaining the novel nano silver ointment. The invention further relates to a sintering method applicable to electronic packaging. Since sintering is assisted by heat generated from self-propagating reactions of the self-propagating powder, the sintering speed can be increased, and the working efficiency can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

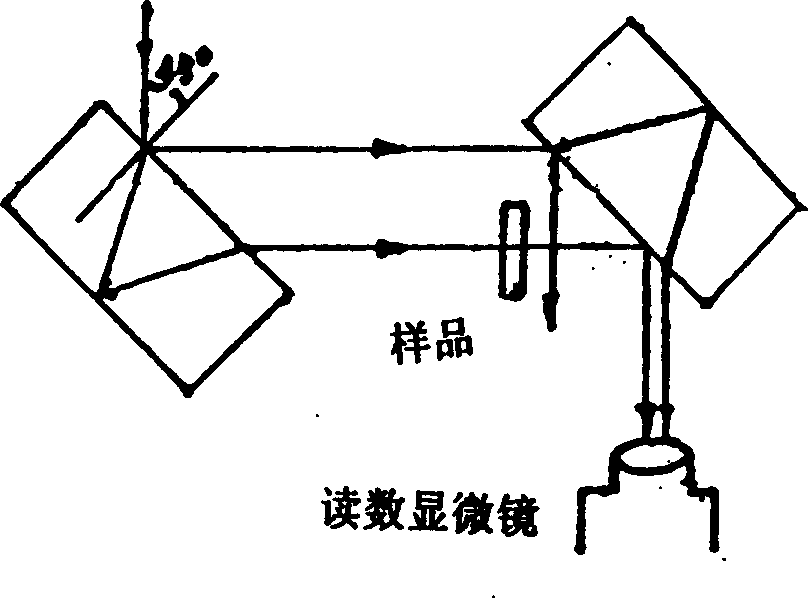

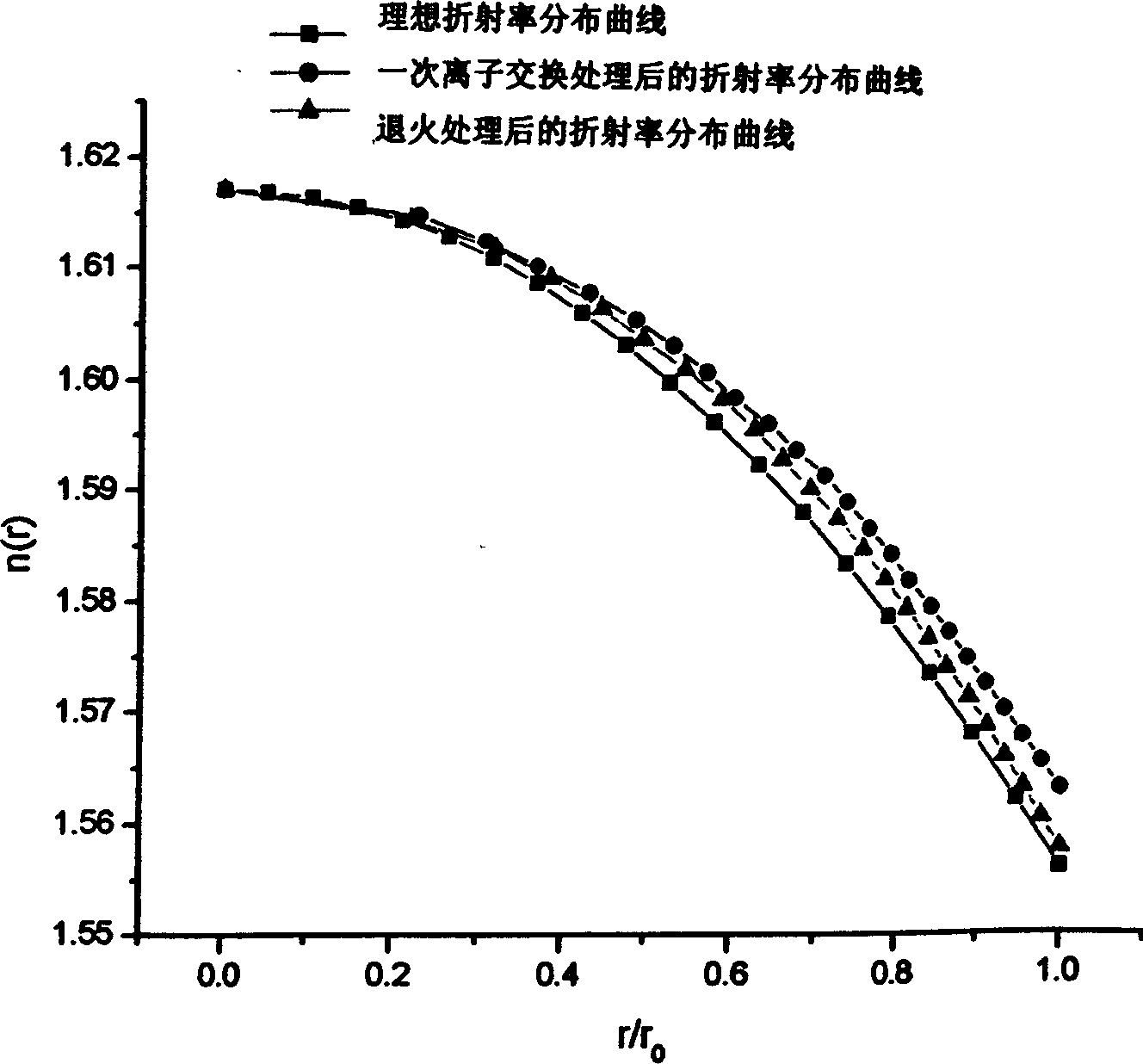

Method for improving aberration characteristic of self-focusing lens

InactiveCN1790062AImproved self-focusing lens aberrationImproved aberration characteristics of self-focusing lensLensYarnIon exchange

The invention discloses a new improvement method of self-focal lens optical aberration character, which comprises the following steps: measuring the refractive index distribution of self-focal lens glass yarn through film interferometric method to obtain different position of the refractive index value and refractive index distribution curve from the center to edge; comparing the obtained curve with the ideal refractive index distribution curve to affirm the biased degree; proceeding the annealing disposal in the heat treatment stove or ion exchanging stove; proceeding the second annealing disposal or adapting second ion exchanging disposal if the optical aberration character is not ideal.

Owner:SOUTHWEST UNIVERSITY

Wound cleaning disinfectant

InactiveCN106421022AReduce manufacturing costSimple preparation processAntisepticsPeroxide active ingredientsDisinfectantMedicine

The invention discloses a wound cleaning disinfectant. The wound cleaning disinfectant is prepared from, by mass, 2-4 parts of benzalkonium chloride, 6-8 parts of radix bupleuri, 2-4 parts of hydrogen peroxide, 7-9 parts of herba cirsii japonici, 2-4 parts of triethanolamine, 4-6 parts of fructus gardeniae, 2-4 parts of hyaluronic acid powder, 4-8 parts of flos sophorae, 7-9 parts of flos chrysanthemi indici and 200-400 parts of water for injection. According to the wound cleaning disinfectant, the production cost is low, the preparation technology is simple, technological conditions are easy to realize, and the product stability is high.

Owner:QINGDAO YUANZHILIN AGRI SCI & TECH DEV

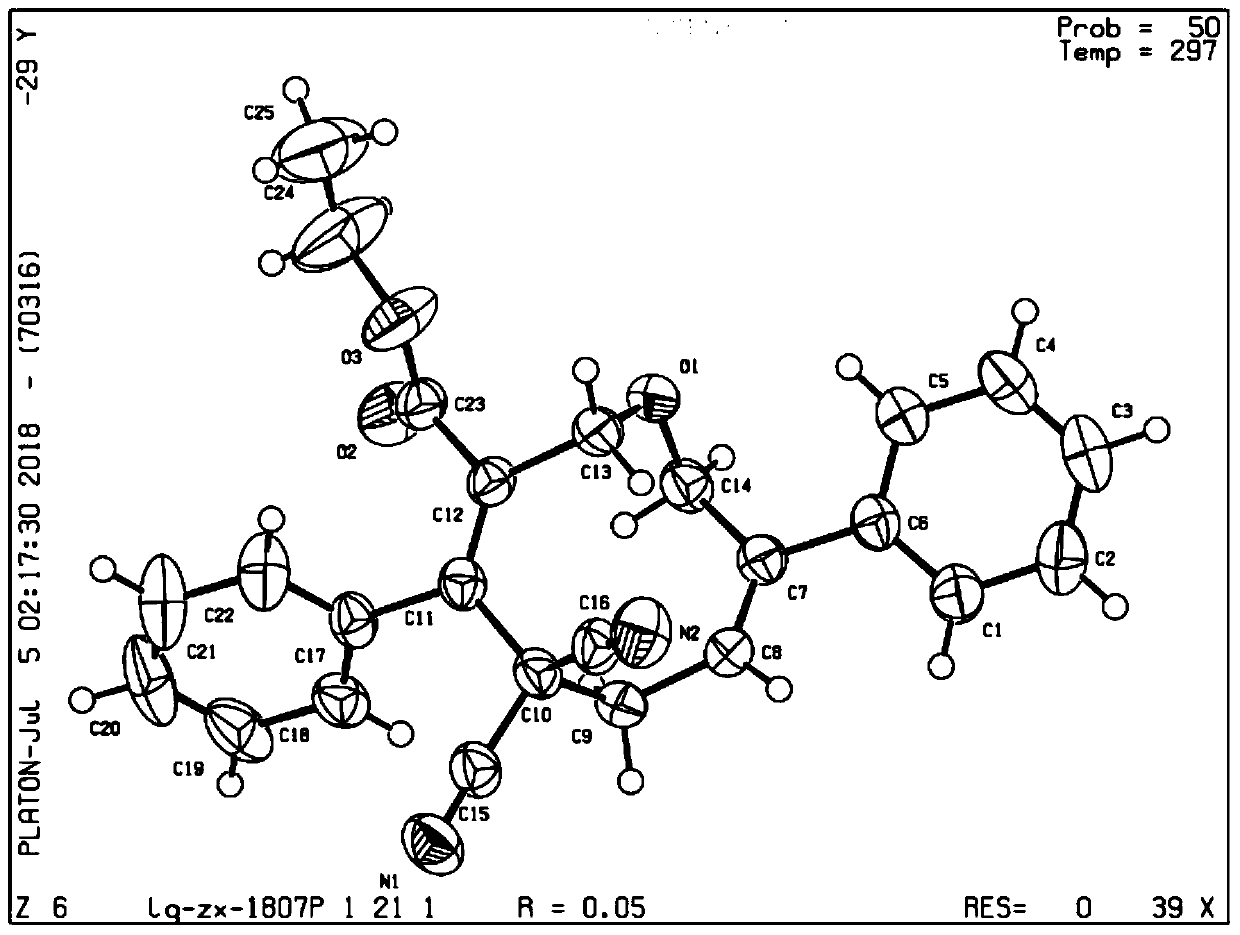

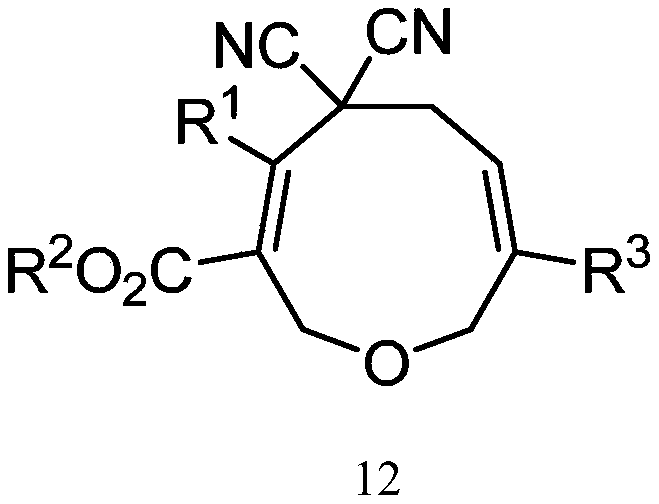

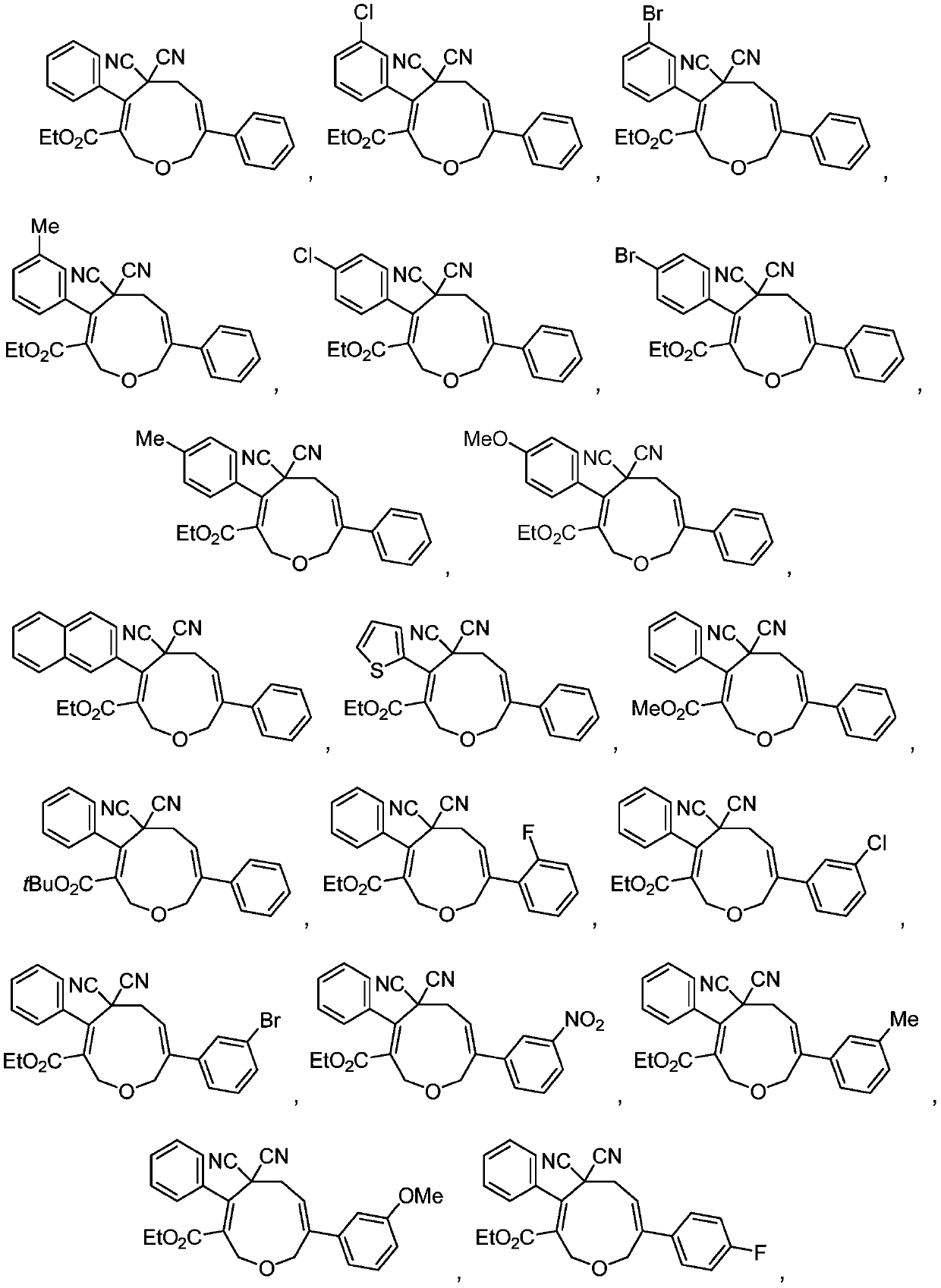

Oxacyclononadiene derivative, and pharmaceutical composition, preparation method and application thereof

PendingCN110845466AGood anti-tumor effectImprove anti-tumor effectOrganic active ingredientsOrganic chemistry methodsAnti-Tumor DrugsPerylene derivatives

The invention provides an oxacyclononadiene derivative, a stereochemical isomer thereof, a solvate thereof or a pharmaceutically acceptable salt thereof. The oxacyclononadiene derivative can achieve arelatively good anti-tumor effect. The invention also provides a preparation method of the oxacyclononadiene derivative. The preparation method comprises the following steps: adding a palladium catalyst into a reactor, then dissolving dicyanodiene and alkenyl cyclic carbonate into a solvent, adding the formed solution into the reactor under the protection of argon, carrying out a reaction for 20-30 hours at a temperature of 15-22 DEG C, and performing concentrating and purifying to obtain the oxacyclononadiene derivative. The preparation method is simple in process, high in yield and convenient for industrial popularization and application. In addition, the invention also provides a pharmaceutical composition with the oxacyclononadiene derivative as an active ingredient and application ofoxacyclononadiene in preparation of antitumor drugs.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

Disinfectant fluid for cleaning oxygen mask for cardiovascular internal medicine and preparation method thereof

InactiveCN104509552AAppearance colorless and transparentStable physical and chemical indicatorsBiocideFungicidesCentella asiatica extractDisinfectant

The invention discloses a disinfectant fluid for cleaning an oxygen mask for cardiovascular internal medicine; the disinfectant fluid comprises the following components by weight: 1-3 parts of peroxyacetic acid, 1-5 parts of hydrogen peroxide, 3-6 parts of metronidazole, 4-9 parts of phenol, 6-10 parts of bohadschia graeffei, 2-6 parts of sodium hypochlorite, and 1-5 parts of a herba centellae extract. The developed disinfectant fluid for ward internal disinfection is colorless and transparent in appearance and stable in physical and chemical indicator performance, generates no crystallization, turbidity and precipitates during use, and has physical and chemical indicators showed stably. Compared with the prior art, the prepared disinfectant has the advantages of low production cost, simple preparation process, easy realization of process conditions, and good product stability; and a volatile oil extracted from traditional Chinese medicines is added, the smell is aromatic, and patients feel blissfully happy.

Owner:聂文红

Application of allium to reduction of content of heterocyclic amine in roasted schrod cakes

InactiveCN110179071ASave raw materialsRaw materials are easy to getFood scienceChemistryHeterocyclic amine

The invention relates to food processing, in particular to an application of allium to reduction of content of heterocyclic amine in roasted schrod cakes. The application comprises the steps of dryingone of onions, leeks, allium mongolicum regel and scallions, performing crushing to obtain powder, making schrod into meat emulsion, uniformly mixing the prepared allium powder with the meat emulsionto prepare the roasted schrod cakes, placing the prepared roasted schrod cakes in an oven, and performing roasting. The application solves the technical problem that in the prior art, the content ofthe heterocyclic amine in the roasted schrod cakes is high, and has the advantages that the raw materials are cheap and easy to obtain, the technology condition is easy to control, and the restrainingeffect on the heterocyclic amine is notable.

Owner:PEKING UNIV

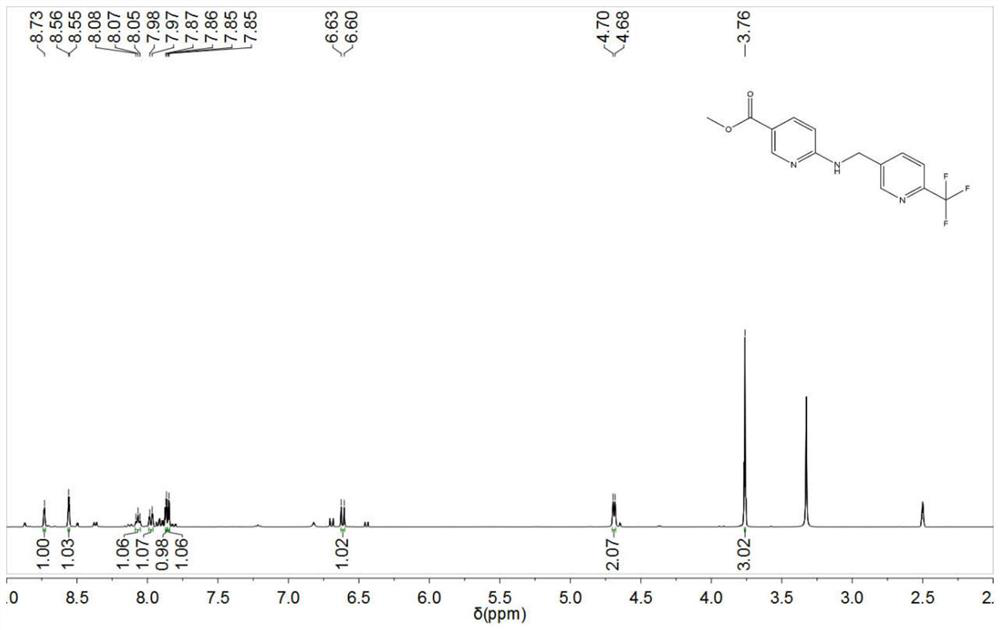

Synthesis method of Pexidartinib intermediate

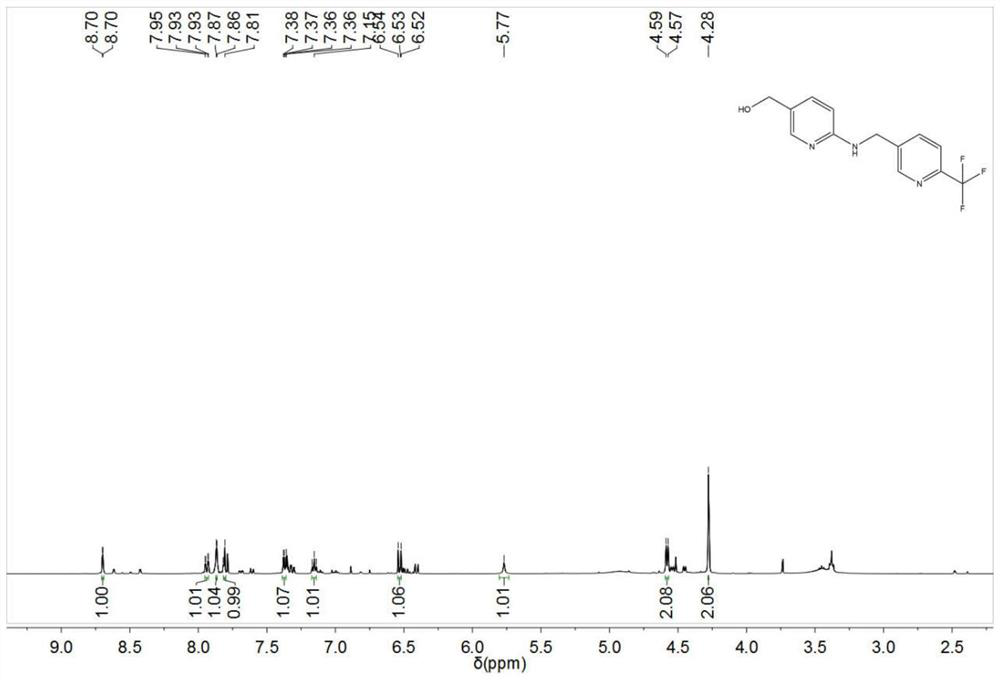

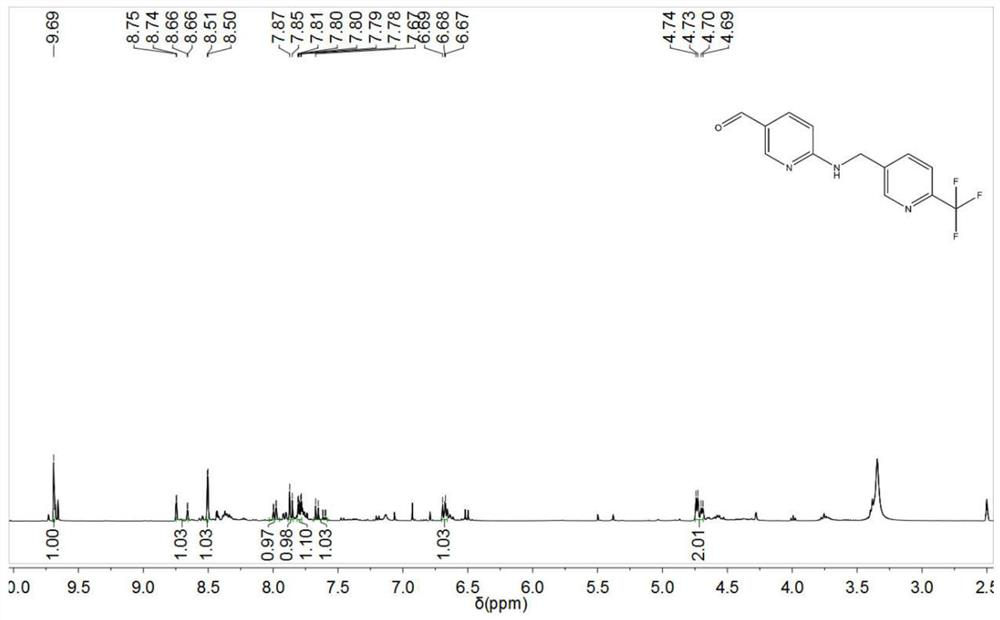

The invention provides a synthesis method of a Pexidartinib intermediate, which specifically comprises the steps of synthesizing a compound I by taking a 6-aminonicotinate compound and 6-trifluoromethyl nicotinaldehyde as raw materials, and generating [6-({[6-(trifluoromethyl) pyridine-3-yl] methyl} amino) pyridine-3-yl] methanol by taking the compound I as a raw material and performing reduction reaction through a reducing agent; and taking [6-({[6-(trifluoromethyl) pyridine-3-yl] methyl} amino) pyridine-3-yl] methanol as a raw material, and generating 6-({[6-(trifluoromethyl) pyridine-3-yl] methyl} amino) pyridine-3-formaldehyde through an oxidizing reaction of an oxidizing agent. The synthesis method disclosed by the invention has the advantages of cheap and easily available raw materials, simplicity and convenience in operation, mild reaction conditions, high yield (the total yield is greater than 58.62%) and the like, large-scale production can be realized, and the production cost of Pexidartinib is reduced, so that the market competitiveness of the product is improved.

Owner:武汉格迪泰健康科技有限公司

Disinfectant used for washing red light therapeutic instruments and preparation method thereof

InactiveCN104206414AAppearance colorless and transparentReduce manufacturing costBiocideDisinfectantsDisinfectantSalicylic acid

The invention discloses a disinfectant used for washing red light therapeutic instruments. The disinfectant contains the following components by weight percent: 0.5-1.0% of peroxyacetic acid, 2.0-5.0% of hydrogen peroxide, 0.1-0.5% of pyridine-2-carboxylic acid, 0.01-0.05% of sodium citrate, 1.0-5.0% of salicylic acid, 2.0-6.0% of ethanol and the balance of water. The disinfectant has the beneficial effects that the production cost of the disinfectant is low; the preparation process is simple; the process conditions are easy to achieve; the product stability is good.

Owner:SHANDONG PROVINCIAL HOSPITAL

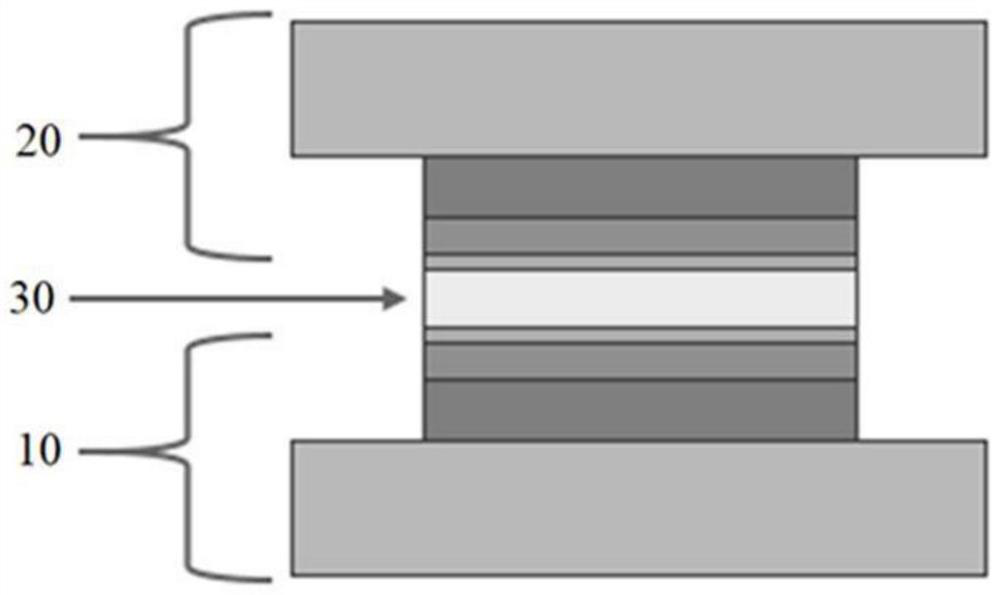

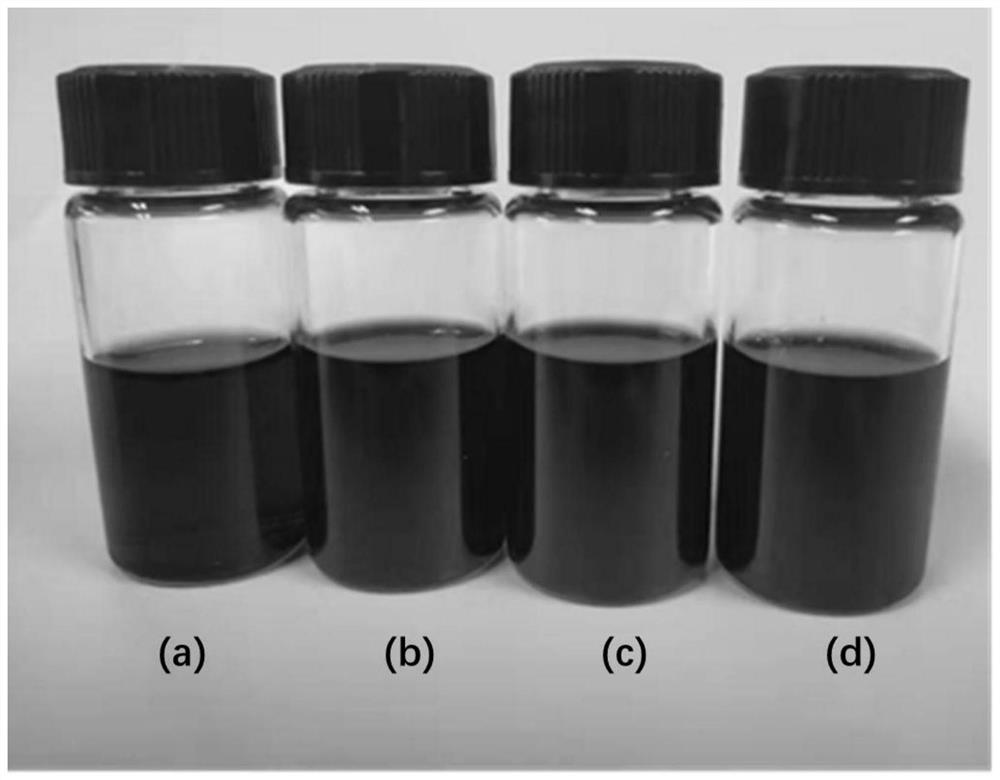

Soldering paste and application thereof

ActiveCN112658529AGood bonding and uniform densityIncreased shear strengthWelding/cutting media/materialsSoldering mediaOrganic solventSolder paste

The invention relates to the technical field of device welding, and particularly discloses soldering paste. The soldering paste comprises flaky nano-silver, a metal organic source and an organic solvent carrier. The invention further discloses application of the soldering paste in an electronic device packaging interconnection structure, the electronic device packaging interconnection structure comprises a first master slice, a second master slice and a connecting layer which is used for connecting the first master slice and the second master slice, the connecting layer is formed by sintering the soldering paste through a sintering process of heating and applying pressure, and in the sintering process, the heating temperature ranges from 130 DE C to 300 DE C, and the pressure applying pressure ranges from 1 MPa to 20 MPa. The soldering paste can be well applied to the field of electronic packaging of low-temperature welding and high-temperature service, the bonding degree of a connecting interface of the connecting layer formed by sintering the solder paste is good, uniform and compact, the shear strength at 150 DE C can reach 51 MPa or above, and the soldering paste has very high shear strength and can be well applied to packaging and interconnection of electronic devices.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

Coupling lubricating solution for B ultrasonic examination

InactiveCN105944119AThe effect of sound transmission is remarkableClear sound effectAntisepticsEchographic/ultrasound-imaging preparationsChemistry

The invention belongs to the technical field of coupling agents and discloses a coupling lubricating solution for B ultrasonic examination. The coupling lubricating solution is prepared according to the following process: step (1), mixing, stirring and heating; step (2), uniformly stirring; step (3), heating and stirring; step (4), extracting with ethanol; and step (5), stirring, sub-packaging and sealing. The coupling lubricating solution has stable physicochemical index performances and has disinfection and sterilization effects.

Owner:孙百梅

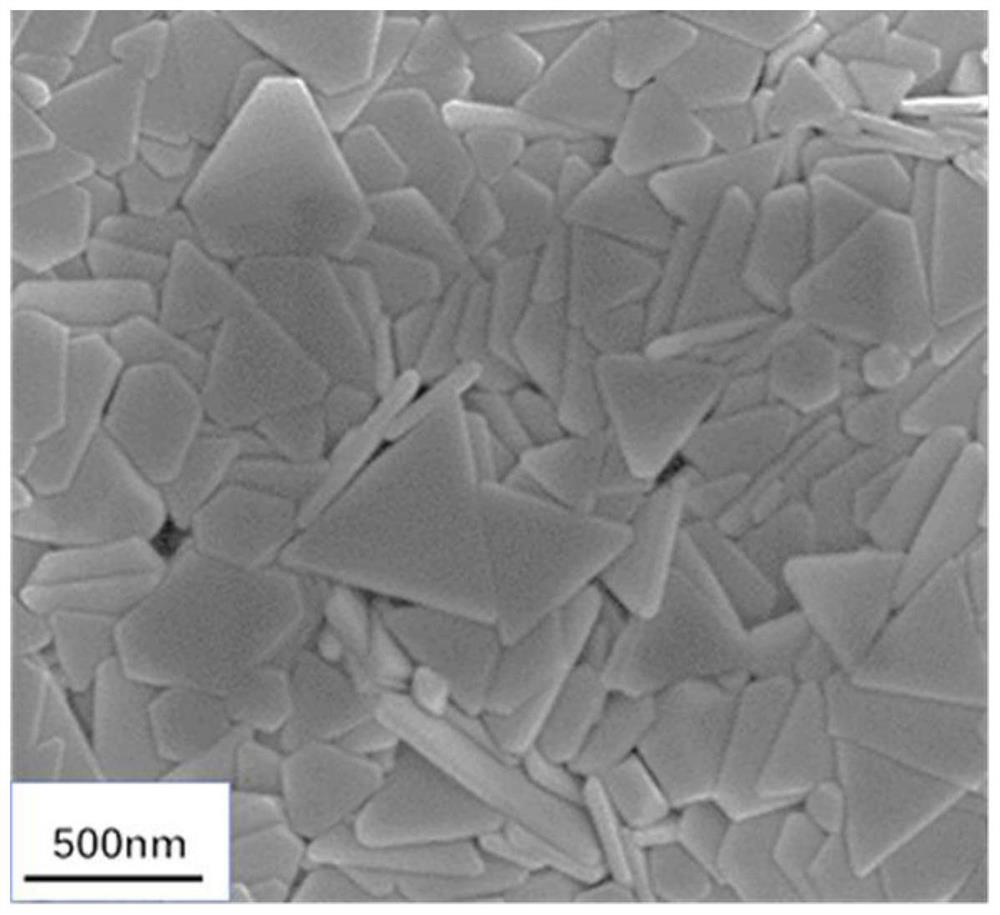

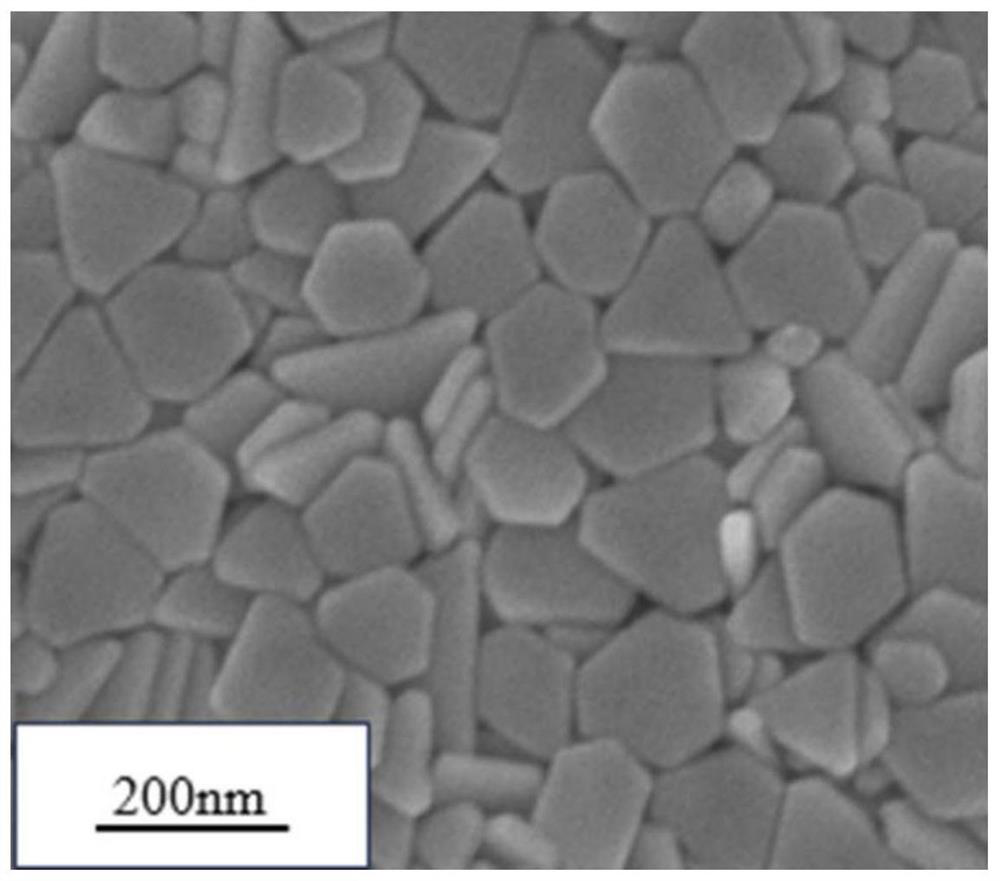

Nano-silver soldering paste, preparation method thereof and application of nano-silver soldering paste in chip packaging interconnection structure

InactiveCN112475662AGood bonding and uniform densityProcess conditions are easy to achieveWelding/cutting media/materialsSoldering mediaSolder pasteDiethylene glycol

The invention provides nano-silver soldering paste and a preparation method thereof. The nano-silver soldering paste comprises flaky nano-silver and an organic solvent carrier which are mixed with each other, wherein the organic solvent carrier is a mixture of any two or more of ethylene glycol, glycerol, diethylene glycol, triethylene glycol, beta terpineol, gamma terpineol and delta terpineol; and the volume percentage of any organic solvent is not less than 20%. The preparation method of the nano-silver soldering paste comprises the following steps of: providing the flaky nano-silver and the organic solvent carrier, and stirring and mixing the flaky nano-silver and the organic solvent carrier to prepare the nano-silver soldering paste. The invention further provides an application of the nano-silver soldering paste in a chip packaging interconnection structure. The nano-silver soldering paste has a low-temperature sintering performance and can be well applied to the field of electronic packaging of low-temperature welding and high-temperature service. A connecting layer formed by sintering the soldering paste is high in shear strength, good in bonding degree of a connecting interface and uniform and compact.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Disinfectant for B-mode ultrasound probe and preparation process of disinfectant

InactiveCN106035391AStable physical and chemical indicatorsReduce manufacturing costBiocideDisinfectantsTriclosanDisinfectant

The invention belongs to the technical field of disinfectants, and discloses a B-ultrasound probe disinfectant, which is prepared from the following raw materials: ethanol, o-phenylphenol, glycerin, dichlorophenoxychlorophen, methyl p-hydroxybenzoate, amino polysaccharides, Sodium Lauryl Sulfate, Vitamin E, Deionized Water, Potassium Iodide, Aluminum Hydroxychloride, Honeysuckle, Black Pepper. The invention adopts the method of combining the chemical disinfectant and the plant extract fungicide, reduces the dosage of the chemical disinfectant, and has good compatibility and synergistic effect.

Owner:于甜甜

Disinfectant for cleaning and disinfecting hemodialysis machine and preparation method thereof

ActiveCN104206413BAppearance colorless and transparentStable physical and chemical indicatorsBiocideDisinfectantsHemodialysisHaemodialysis machine

The invention discloses a disinfectant solution for cleaning and disinfecting hemodialysis machines. The product contains 0.5%-1.0% of peracetic acid, 2.0%-5.0% of hydrogen peroxide, and 0.1% of pyridine-2-carboxylic acid in terms of components by weight. %-0.5%, sodium citrate 0.01%-0.05%, sodium dichloroisocyanurate 0.2%-2.0%, sulfamic acid 0.05%-1.0%, and the balance is water. The invention has the advantages of simple preparation process, convenient use, easy realization of process conditions and good product stability.

Owner:南通江海港建设工程有限公司

A sterilizing agent used for apparatus in a room for B-scan ultrasonography and a preparing method thereof

ActiveCN106075500AEasy to wipe offStable physical and chemical indicatorsBiocideDead animal preservationB-scan ultrasonographyChemistry

The invention belongs to the technical field of medical sterilizing agents and discloses a sterilizing agent used for apparatus in a room for B-scan ultrasonography. The sterilizing agent is prepared by steps of 1) mixing and stirring, 2) stirring and allowing the mixture to stand, 3) fully stirring, 4) heating and stirring, 5) extracting with ethanol, concentrating and crushing and 6) stirring, subpackaging and sealing. The sterilizing agent is stable in performance and simple in preparing process.

Owner:刘敏

Disinfectant for radiotherapy department

InactiveCN106035390AReduce dosageEasy to wipe offBiocideDead animal preservationDisinfectantCombinatorial chemistry

The invention belongs to the technical field of medical disinfectants and discloses a disinfectant for the radiotherapy department. The disinfectant is prepared according to the following process which comprises a step 1) of preparing a material A, a step 2) of preparing a material B, a step 3) of preparing a material C, a step 4) of preparing a material D, a step 5) of preparing a material E and a step 6) of preparing the disinfectant. The disinfectant is good in sterilizing effect, high in stability and wide in application prospect.

Owner:寻航

Process for extracting diosgenine from turmeric by catalytic hydrolysis method

The invention discloses a process for extracting diosgenine from turmeric by a catalytic hydrolysis method, which comprises the following steps of: crushing a turmeric raw material subjected to cellulose and starch removal to prepare a refined raw material; adding 0.02 to 0.02mol / L aqueous solution of catalyst into the refined raw material, heating and pressurizing to perform catalytic hydrolysis, and obtaining hydrolysis products, wherein the catalyst is one of transition metal salt, bipyridyl chelate of the transition metal salt, and tri(2-picolyl) amine complex of the transition metal salt, or a mixture of the transition metal salt and the bipyridyl chelate of the transition metal salt, or a mixture of the transition metal salt and the tri(2-picolyl) amine complex of the transition metal salt; and finally, dissolving the hydrolysis products with an organic solvent, extracting and crystallizing to obtain the diosgenine. The diosgenine is extracted from the turmeric by the catalytic hydrolysis method, the generation of a great deal of acid wastewater is avoided, and the environment is protected. Moreover, the catalyst in the process is a common compound, the process conditions are easily met, and the process can be promoted and applied.

Owner:HUBEI UNIV

Method and device for recovering waste silicon powder from trichlorosilane synthetic furnace

A method for recovering waste silicon powder from the trichlorosilane synthetic furnace comprises the synthetic furnace and a silicon powder collection tank, and includes steps: A, replacing the synthetic furnace after the synthetic furnace stops normally; B, after replacement is qualified, connecting a silicon powder discharging valve at the bottom of the synthetic furnace with the silicon powder collection tank through a metal hose, and feeding nitrogen into the synthetic furnace through a nitrogen inlet pipeline; and C, turning on the silicon powder discharging valve to enable the silicon powder along with the nitrogen to be brought into the silicon powder collection tank, and emptying the nitrogen through a cloth bag filter at the top of the silicon powder collection tank to enable the silicon powder to be collected into the silicon powder collection tank, so that the silicon powder is fully recycled. The method for recovering waste silicon powder from the trichlorosilane synthetic furnace has the advantages that the method is simple in process, easy in implementation of process conditions and convenient to operate; and waste silicon powder in the synthetic furnace can be fully recycled in reproduction, and dust hazards to personnel bodies during recovery can be avoided. The invention further discloses a device for recovering waste silicon powder from the trichlorosilane synthetic furnace.

Owner:XINTE ENERGY

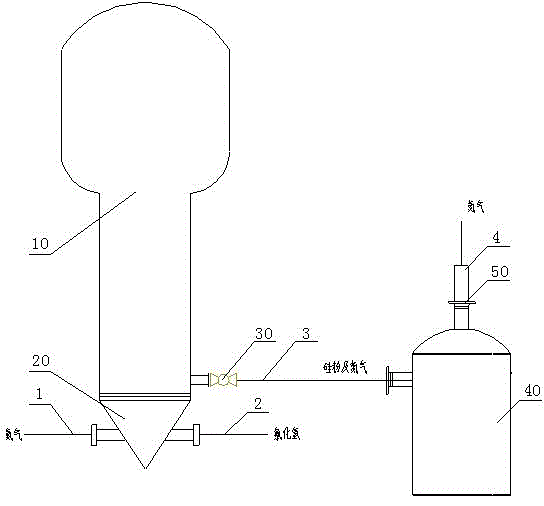

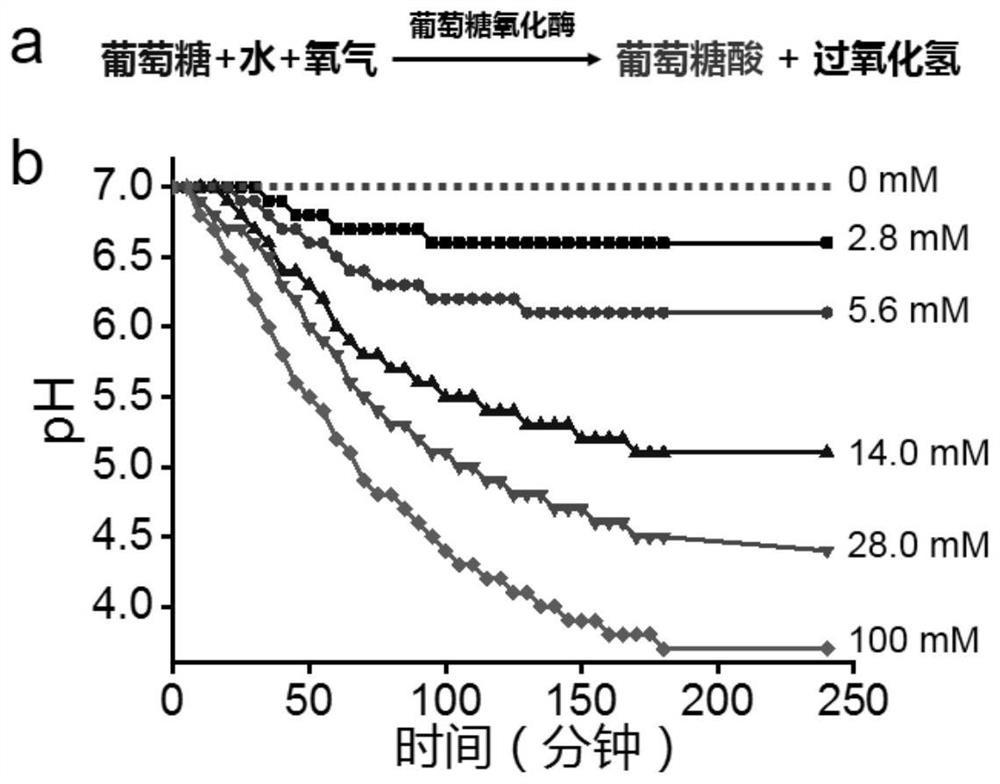

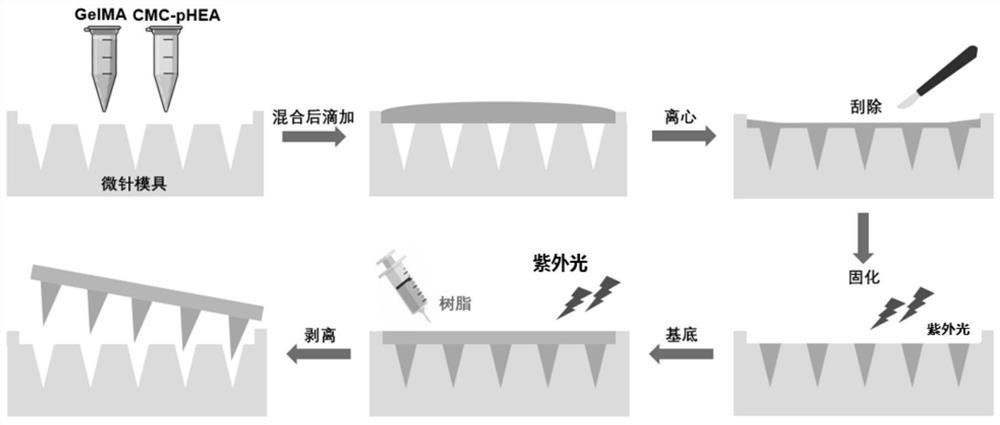

Hydrogel microneedle patch for noninvasive blood glucose detection as well as preparation method and application of hydrogel microneedle patch

PendingCN114847938ADetection visualizationDetecting Visualized In Vivo Blood Glucose RapidlyCatheterSensorsUltraviolet lightsGlucose detection

The invention discloses a hydrogel microneedle patch for noninvasive blood glucose detection as well as a preparation method and application of the hydrogel microneedle patch. According to the invention, the microneedle patch is prepared by a turnover technology and is noninvasively applied to the skin surface, so that simple and rapid extraction of interstitial fluid in vivo and a new method for real-time, rapid and quantitative detection of blood glucose in vivo are realized. The hydrogel microneedle patch contains two hydrogel components: one hydrogel component is hydrogel which can be cured and formed by ultraviolet light, and the other hydrogel component is hydrogel which can be cured and formed by ultraviolet light; and the other hydrogel is functional hydrogel with pH responsiveness, and glucose oxidase is added, so that the hydrogel can sensitively react to in-vivo glucose. The double-response hydrogel is jointly mixed and prepared into a microneedle patch form, the microneedle patch is endowed with noninvasive / minimally invasive property when applied to the skin surface, the microneedle patch is very suitable for extraction of interstitial fluid in vivo, and then real-time, rapid and accurate detection of the blood glucose level in vivo is achieved.

Owner:WUHAN UNIV

Method and equipment for intermittently recycling waste liquid of chlorosilane during polycrystalline silicon production

ActiveCN102910633BImprove handling of difficult problemsReduce wasteHalogenated silanesProcess engineeringEnvironmental engineering

The invention discloses a method for intermittently recycling chlorosilane in discharged waste liquid in a washing tower during polycrystalline silicon production, and the method the following steps of: intermittently charging a chlorosilane waste liquid produced in polycrystalline silicon production into an evaporation device at different places, evaporating trichlorosilane and silicon tetrachloride with lower boiling point into a gas state when the temperature of the evaporation device is controlled at 120-180DEG C and the pressure of the evaporation device is controlled at 0.1-0.6MPa, and charging the gaseous trichlorosilane and silicon tetrachloride into a rectifying tower so as to be purified and recycled. The invention further provides the evaporation device used in the method. The invention has the beneficial effects that the method is simple in process, the process condition is easy to realize, and the method is convenient to operate; and the treatment difficulty of the chlorosilane waste liquid during polycrystalline silicon production in the process of production can be improved, the discharge quantity of exhaust liquor can be mainly reduced, the waste of the chlorosilane can be reduced, the treatment load of an alkali liquor pond can be reduced, the environment pollution problem can be remitted, the labor quantity can be reduced, the production cost can be reduced, the complete recycle of the chlorosilane can be realized, and the phenomenon of equipment blockage can be avoided.

Owner:XINTE ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com