Heat conduction composite material and preparation method thereof

A technology of thermally conductive composite materials and thermally conductive fillers, applied in the field of thermally conductive composite materials and their preparation, can solve problems such as poor thermal conductivity, achieve the effects of improving thermal conductivity, increasing wettability, and being beneficial to large-scale industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

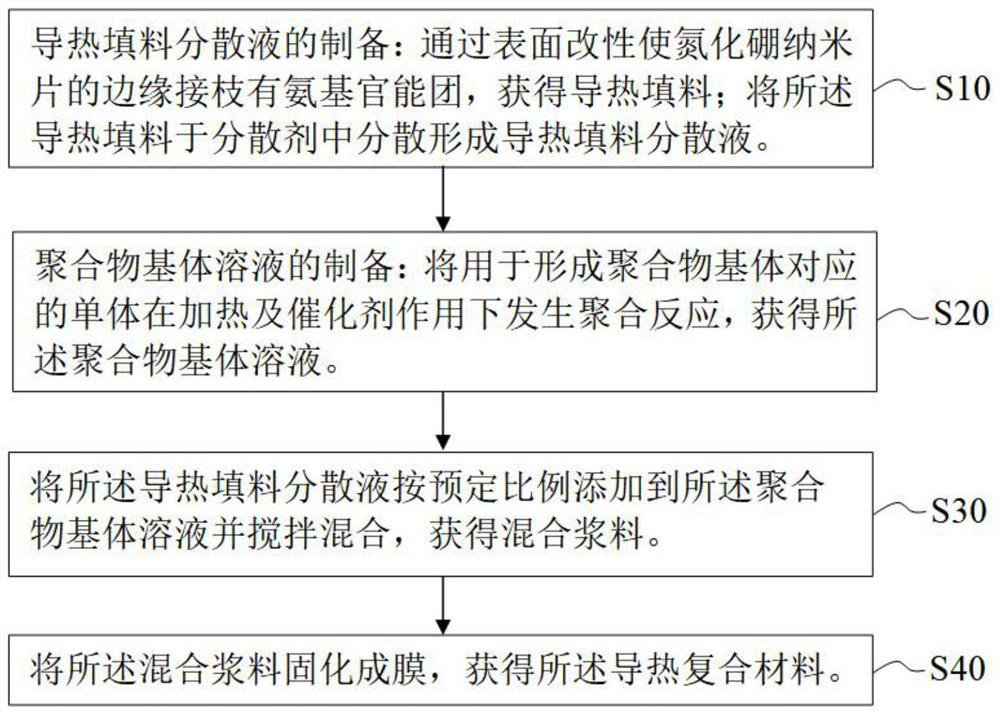

[0037] The embodiment of the present invention also provides the preparation method of the above-mentioned heat-conducting composite material, refer to figure 1 , the preparation method comprises:

[0038] S10. Preparation of thermally conductive filler dispersion: grafting amino functional groups on the edges of boron nitride nanosheets through surface modification to obtain thermally conductive fillers; dispersing the thermally conductive fillers in a dispersant to form a thermally conductive filler dispersion.

[0039] In the preferred scheme, hexagonal boron nitride is used as raw material, urea is used as modifier, hexagonal boron nitride is mixed with urea and ball milling aid is added, and then placed in ball milling equipment for ball milling process to obtain edge-grafted amino groups. Functional group boron nitride nanosheet powder. Then, the boron nitride nanosheet powder is washed and dried, and then added to the dispersion liquid for dispersion to obtain the ther...

Embodiment 1

[0058] Embodiment 1: Preparation of thermally conductive filler dispersion

[0059] Hexagonal boron nitride, urea and sodium chloride are mixed in the planetary ball mill according to the mass ratio of 1:20:5, and the N 2 Under the protection of the atmosphere, at a speed of 500r / min, use ZrO with ball diameters of 10mm and 1mm respectively. 2 Grinding balls, ball milling for 10 hours. Wash and dry the obtained powder with deionized water to remove excess urea and sodium chloride to obtain pure boron nitride nanopowder, and then choose deionized water as a dispersant to make pure boron nitride nanopowder The body is dispersed in deionized water, and finally a pure and stable thermal conductive filler is obtained. The urea added during the ball milling process modified the boron nitride nanosheets, and grafted -NH 2 functional group.

Embodiment 2

[0060] Embodiment 2: the preparation of polymer matrix solution

[0061] In this embodiment, the polymer matrix is selected as cyanate resin, and its preparation process is as follows:

[0062] Put 7g of bisphenol A type cyanate ester monomer and catalyst (dibutyltin dilaurate, 0.05g) into the reaction vessel successively, heat with an oil bath, the heating temperature is 90°C, the heating time is 30min, and polymerize After the reaction is completed, a light yellow transparent cyanate polymer liquid is obtained, that is, a polymer matrix solution is obtained.

[0063] Add 3g of E51 type epoxy resin to the prepared cyanate polymer solution, continue stirring and heating for 15min to obtain a mixture of cyanate resin and epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com