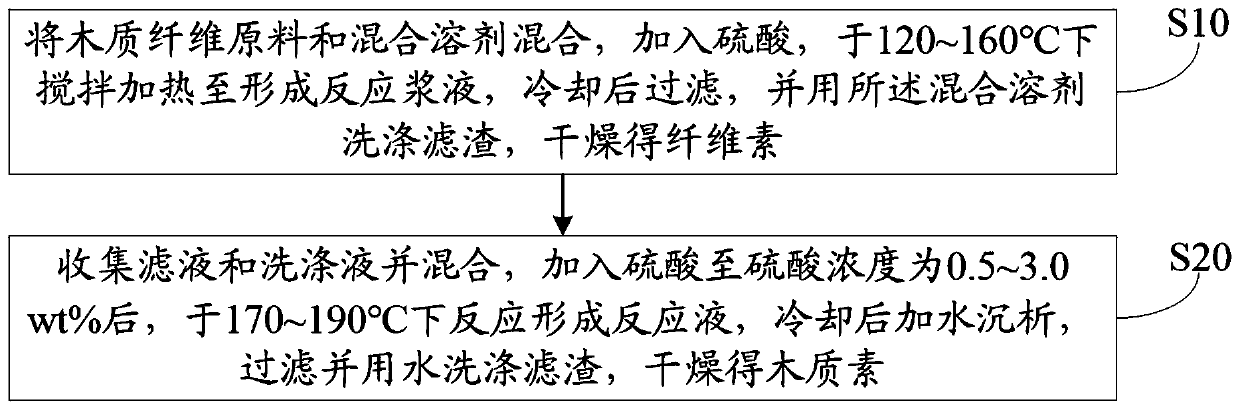

Method for separating lignin and cellulose from lignocellulose raw material

A lignocellulose and cellulose technology, applied in the field of resources and the environment, can solve the problems of low lignin yield and product quality, and difficulty in obtaining high-purity cellulose and lignin at the same time, so as to improve utilization rate and value, Ease of industrialization promotion and the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Pretreatment: Wash the wheat straw raw material, dry it, then pulverize it into powder, sieve it, add toluene-ethanol (2:1, v / v) mixed solvent, wherein, the weight volume of the raw material and the mixed solvent The ratio is 1:15 (g:mL). Then extract at 100° C. for 24 hours to obtain an extract, and vacuum-dry at 80° C. to obtain pretreated wheat straw powder, which is ready for use.

[0048] Separation of cellulose: Mix 10g wheat straw powder, 150mL 1,4-dioxane / water (volume ratio: 2:1) mixed solvent, then add sulfuric acid until the concentration of sulfuric acid in the mixture is 1.0wt%, and then add To the autoclave, stirred at 150 ° C for 6h. After the reaction kettle was cooled, the reaction slurry in the reaction kettle was filtered, and the obtained filter residue was washed 3 times with 25 mL of the above-mentioned mixed solvent, freeze-dried, and weighed to obtain cellulose, and the purity of the cellulose was 86.8%.

[0049] Separation of lignin: collect t...

Embodiment 2

[0051] Except that in the step of separating lignin, "supplementing sulfuric acid to a sulfuric acid concentration of 1.5 wt%" was changed to "supplementing sulfuric acid to a sulfuric acid concentration of 2.0 wt%", other steps were the same as in Example 1. After testing, the purity of the isolated cellulose is 86.8%; the purity of lignin is 89.2%, and the yield is 15.6%.

Embodiment 3

[0053] Except that in the step of separating lignin, "react at 180°C for 2.5h" was changed to "react at 180°C for 6h", other steps were the same as in Example 1. After detection, the purity of the isolated cellulose is 86.8%; the purity of lignin is 91%, and the yield is 16.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com