Preparation method of inorganic-organic hybrid monolithic column

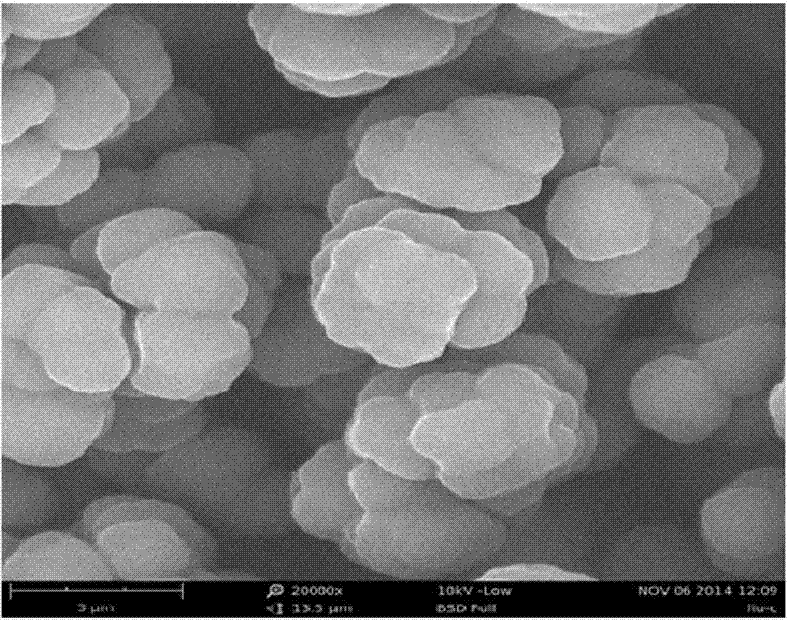

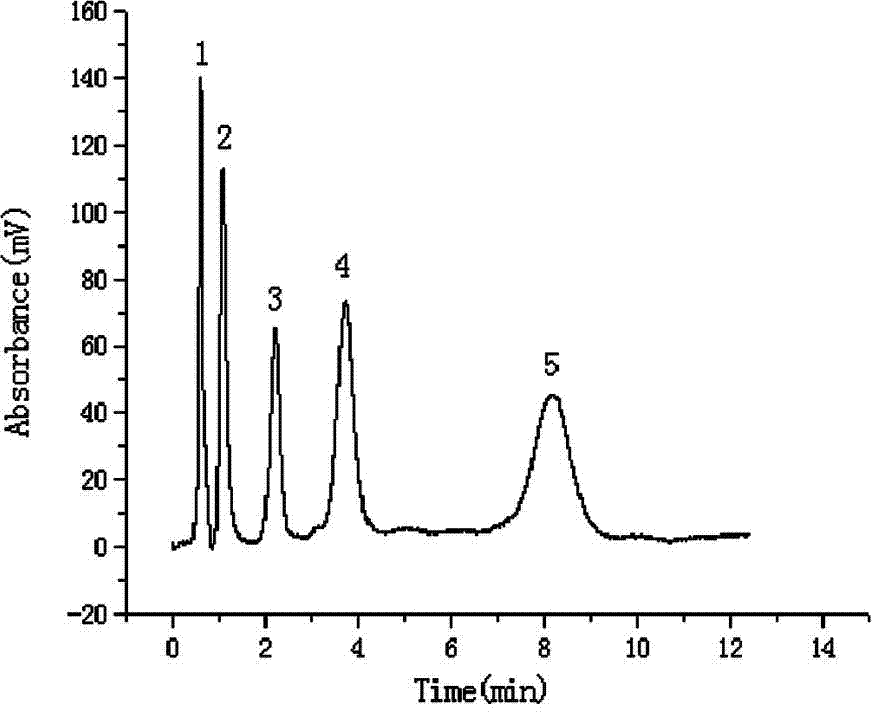

An organic hybrid, monolithic column technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of uneven pore structure, small surface area, poor separation effect, etc., to achieve good separation effect, skeleton and Uniform pore size and short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

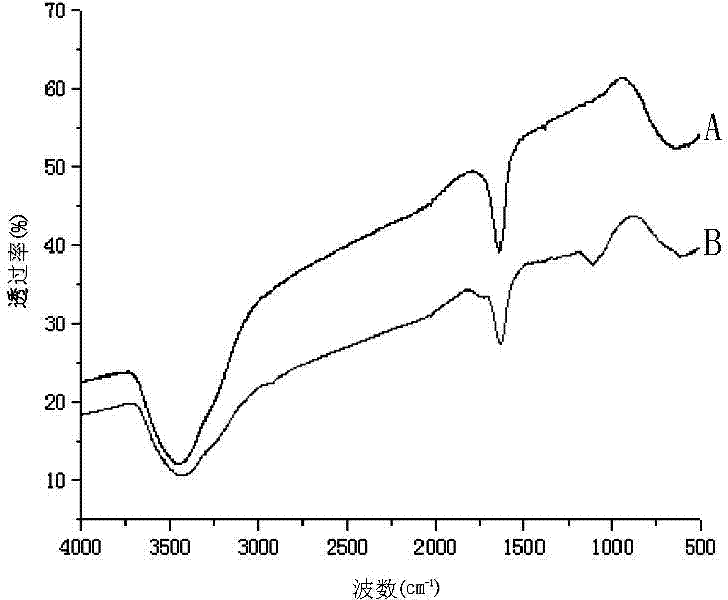

[0022] (1) Hydroxylation of nanodiamonds by Fenton’s reagent reflux method: take 6.95g FeSO 4 ·H 2 O, add a little (about 10-30ml) distilled water to dissolve completely, adjust the pH of the solution to 3.0 with concentrated sulfuric acid, add 0.1g of nano-diamonds with a particle size of 80 nm to the solution, stir and mix, add 42.5g dropwise while stirring H with a mass fraction of 30% 2 o 2 , making nanodiamonds in Fe 2+ : H 2 o 2 The molar ratio is 1:15, and the temperature is 80 °C for 5 h under reflux reaction to obtain hydroxylated nano-diamonds. The infrared spectrum is as follows figure 2 As shown in B, the infrared spectrum of the nano-diamond before the reaction is as follows figure 2 As shown in A;

[0023] (2) Take the hydroxyl nanodiamond prepared in step (1) and KH of the same mass as the hydroxyl nanodiamond 570 (γ-methacryloxypropyltrimethoxysilane) was mixed and dissolved in 30ml of ethanol with a concentration of 95% (v / v), ultrasonically treated ...

Embodiment 2

[0026] (1) Hydroxylation of nanodiamonds by Fenton’s reagent reflux method: Take 5.69g FeSO 4 , add a little (about 10-30ml) distilled water to dissolve completely, adjust the pH of the solution to 2.8 with concentrated sulfuric acid, add 0.1g of nano-diamonds with a particle size of 60 nm in the solution, stir and mix, add 34.8g of mass dropwise while stirring H with a score of 30% 2 o 2 , making nanodiamonds in Fe 2+ : H 2 o 2 The molar ratio is 1:15, and the temperature is 75°C for reflux reaction for 6 hours to obtain hydroxylated nano-diamonds;

[0027] (2) Take the hydroxyl nanodiamond prepared in step (1) and KH of the same mass as the hydroxyl nanodiamond 570 (γ-methacryloxypropyltrimethoxysilane) was mixed and dissolved in 30ml of ethanol with a concentration of 95% (v / v), ultrasonically treated for 1.5 hours, and reacted at a constant temperature of 55°C for 6.5 hours, and then the reaction The product was centrifuged at 15,000 r / min for 8 min, and unreacted KH...

Embodiment 3

[0030] (1) Hydroxylation of nanodiamonds by Fenton’s reagent reflux method: take 7.79g FeSO 4 ·H 2 O, add a little (about 10-30ml) distilled water to dissolve completely, adjust the pH of the solution to 3.2 with concentrated sulfuric acid, add 0.1g of nano-diamonds with a particle size of 80 nm to the solution, stir and mix, and add 47.6g dropwise while stirring H with a mass fraction of 30% 2 o 2 , making nanodiamonds in Fe 2+ : H 2 o 2 The molar ratio is 1:15, and the temperature is 85°C for reflux reaction for 4 hours to obtain hydroxylated nano-diamonds;

[0031] (2) Take the hydroxyl nanodiamond prepared in step (1) and KH of the same mass as the hydroxyl nanodiamond 570 (γ-methacryloxypropyltrimethoxysilane) mixed and dissolved in 30ml of ethanol with a concentration of 95% (v / v), ultrasonically treated for 2.5 hours, and reacted at a constant temperature of 65°C for 5.5 hours, and then the reaction The product was centrifuged at 15,000 r / min for 8 min, and unrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com