Preparation method of silica gel monolithic column

A silica monolithic column, silica gel technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problem of high difficulty in synthesis technology, and achieve the effect of good fracture shrinkage and control of fracture shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

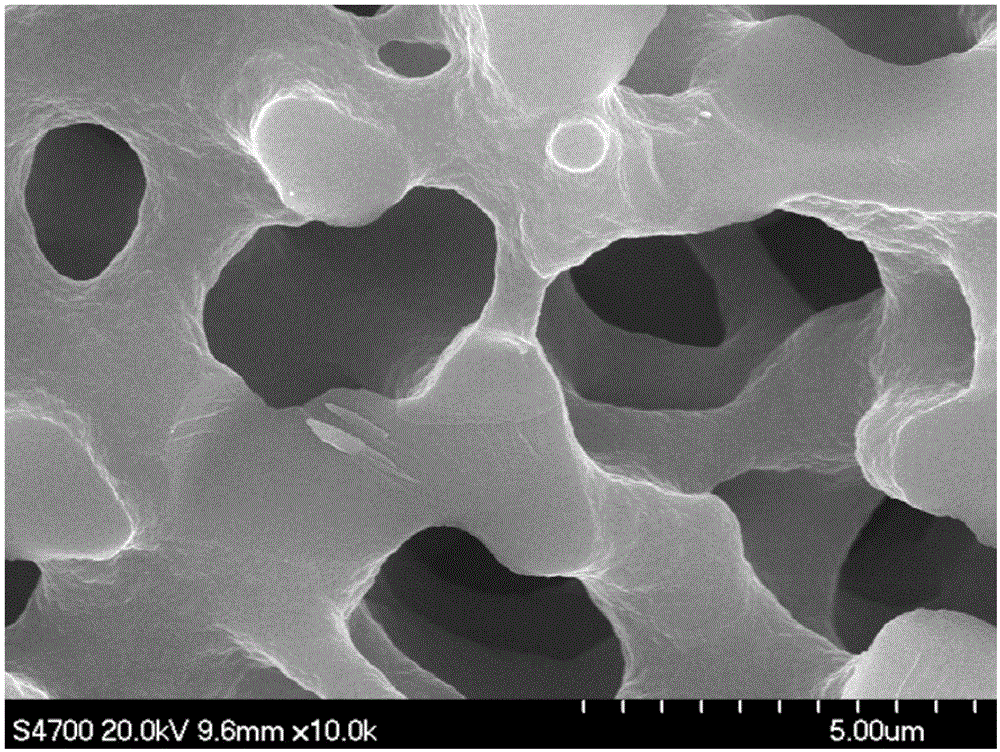

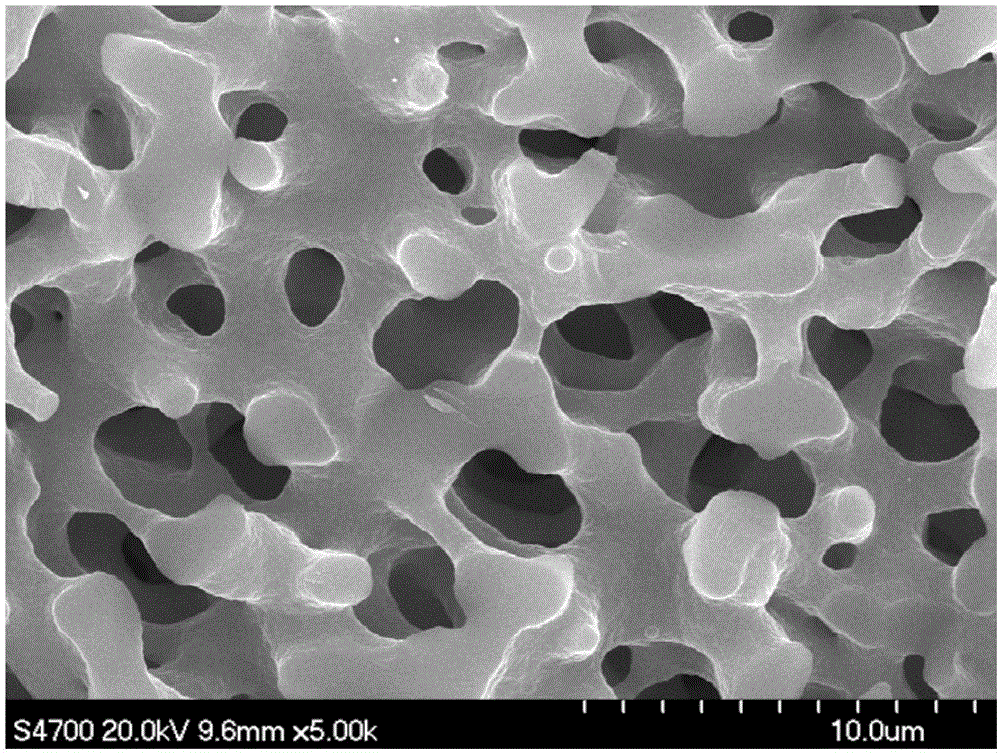

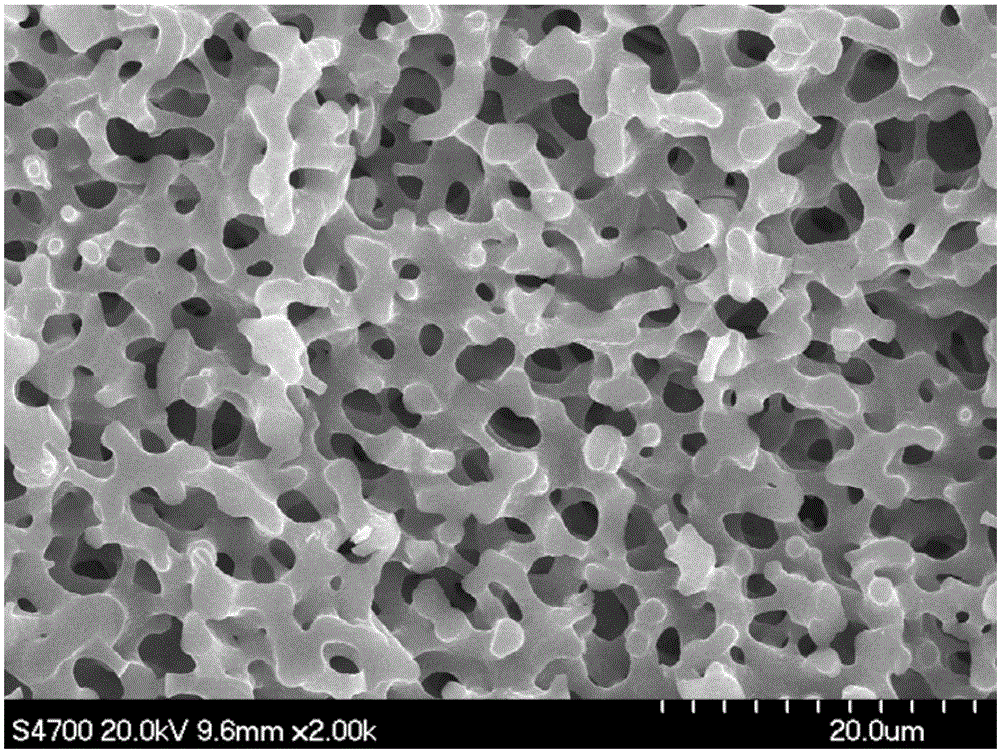

Image

Examples

Embodiment 1

[0024] A. In a three-necked flask equipped with a stirring device, the solid content is 44.77g of 25% silica gel, and 3.64g of analytically pure polyethylene glycol is added, and after stirring for 20min, it is completely dissolved to form a homogeneous solution, and then the device is placed in In an ice-water bath at a temperature of 0°C to 5°C, add distilled water dropwise to adjust the pH of the system to 9, continue stirring for 10 minutes, then add analytically pure methyl orthosilicate 3.1mL dropwise, stir for 15 minutes, and wait until it is completely in the system Install the tube after hydrolysis, and seal the two ends of the tube.

[0025] B. The monolithic column prepared in above A is placed in a 40°C water bath for sol-gel aging for 24 hours. After the column is gelled, the sealing films at both ends are removed, the column is placed in a larger petri dish, and 0.01mol / L, 0.1mol / L, 1mol / L ammonia water 200mL soaked for 3 hours each to prepare mesopores, then so...

Embodiment 2

[0028] A. In a three-necked flask equipped with a stirring device, the solid content is 25% silica gel 39.8g, and 3.64g of analytically pure polyethylene glycol is added, and after stirring for 20min, it is completely dissolved to form a homogeneous solution, and then the device is placed in In an ice-water bath at a temperature of 0°C to 5°C, add distilled water dropwise to adjust the pH of the system to 9. After continuing to stir for 10 minutes, add 6.2 mL of analytically pure methyl orthosilicate dropwise. After stirring for 15 minutes, wait until it is completely in the system. Install the tube after hydrolysis, and seal the two ends of the tube.

[0029] B. The monolithic column prepared in above A is placed in a 40°C water bath for sol-gel aging for 24 hours. After the column is gelled, the sealing films at both ends are removed, the column is placed in a larger petri dish, and 0.01mol / L, 0.1mol / L, 1mol / L ammonia water 200mL soaked for 3 hours each to prepare mesopores...

Embodiment 3

[0032] A. In a three-necked flask equipped with a stirring device, add 34.8 g of silica gel with a solid content of 25%, and add 3.64 g of analytically pure polyethylene glycol. After stirring for 20 minutes, wait for it to completely dissolve to form a homogeneous solution, and then place the device In an ice-water bath at a temperature of 0°C to 5°C, add distilled water dropwise to adjust the pH of the system to 9, continue stirring for 10 minutes, then add analytically pure methyl orthosilicate 9.3mL dropwise, stir for 15 minutes, and wait until it is in the system Fill the tube after complete hydrolysis, and seal the two ends of the tube.

[0033] B. The monolithic column prepared in above A is placed in a 40°C water bath for sol-gel aging for 24 hours. After the column is gelled, the sealing films at both ends are removed, the column is placed in a larger petri dish, and 0.01mol / L, 0.1mol / L, 1mol / L ammonia water 200mL soaked for 3 hours each to prepare mesopores, then so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com