A preparation method of a macroporous organic-inorganic hybrid monolithic column with a hydrophilic outer surface

A hydrophilic, monolithic column technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of poor interference ability of purification matrix, easy adhesion to the surface, short service life, etc., and achieve uniform skeleton , Not easy to shrink and deform, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

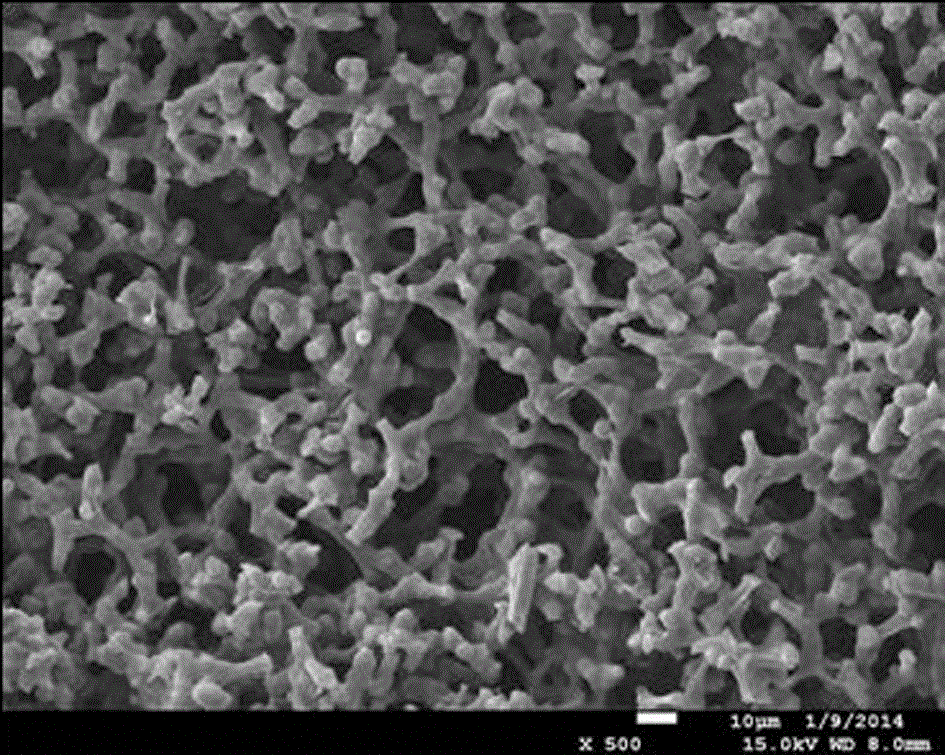

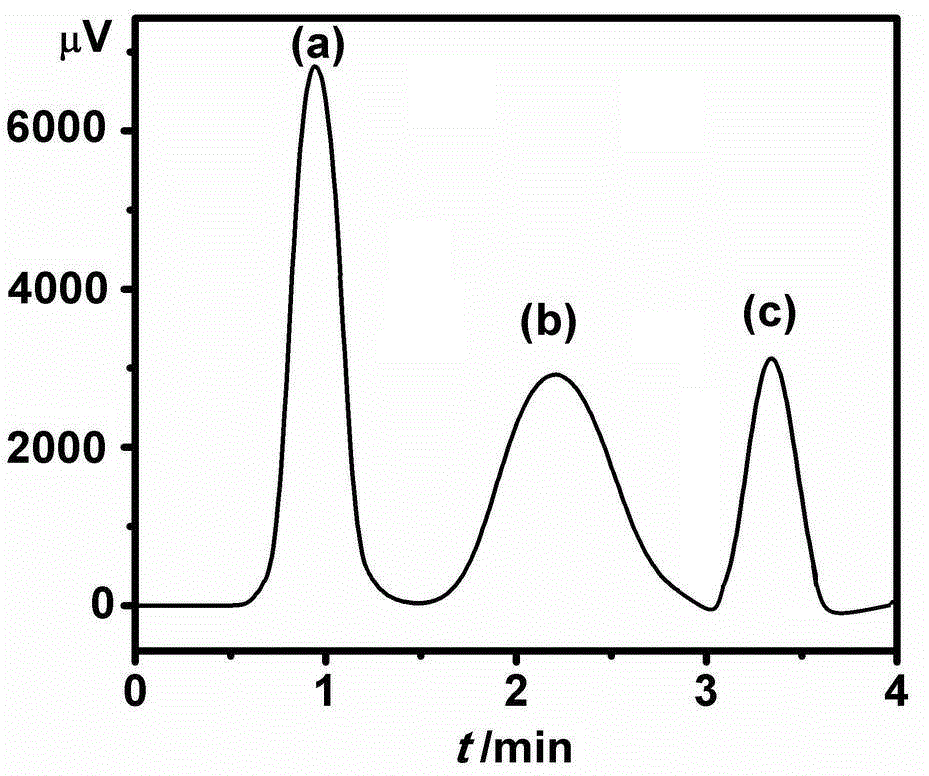

[0023] (1) Mix 2:1 organic precursor methyltrimethoxysilane (MTMS) and inorganic precursor tetraethoxysilane, take 2 mL of the mixture and 0.75 mL of porogen methanol and the molar concentration is 1.0 mol / L The catalyst was mixed with 0.55 mL of concentrated nitric acid solution, ultrasonicated, poured into a stainless steel column, sealed, and stood vertically in a 40°C water bath for 12 h; connected to a high-pressure infusion pump, with a flow rate of 0.05 mL / min, methanol and Rinse with N,N-dimethylformamide for 2 h, and dry at 40°C; then connect the high-pressure infusion pump, and wash with methanol, 0.1 mol / L hydrochloric acid, water, and methanol respectively at a flow rate of 0.05 mL / min for 2 h. h, the remaining solvent was blown dry with nitrogen gas to obtain a macroporous organic-inorganic hybrid monolithic column.

[0024] (2) Connect the dried macroporous organic-inorganic hybrid silica monolithic column to a high-pressure infusion pump, and continuously inject...

Embodiment 2

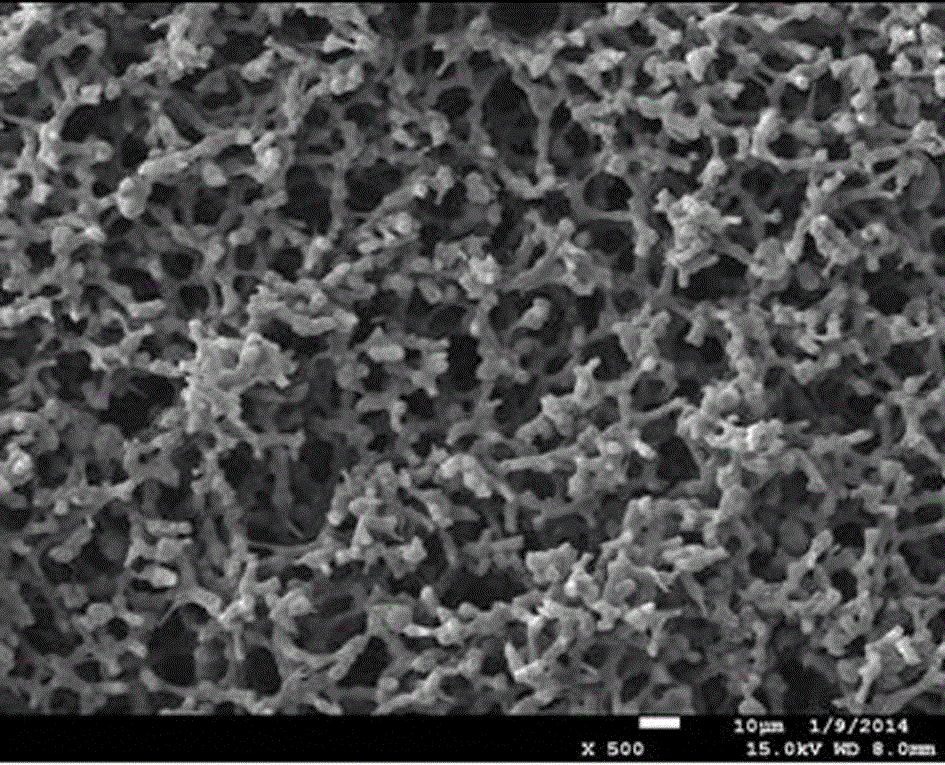

[0027] In step (1) of Example 1, 1:1 organic precursor methyltrimethoxysilane and inorganic precursor tetraethoxysilane (TEOS) were added, and the others were the same as in Example 1.

Embodiment 3

[0029] In the step (1) of Example 1, a 1:2 ratio of organic precursor methyltrimethoxysilane and inorganic precursor tetraethoxysilane was added, and the others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com