Novel nano silver ointment as well as preparation method and sintering method thereof

A sintering method and nano-silver technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex sintering and connection process of nano-silver paste, long sintering time, and low efficiency. , to achieve the effect of improving sintering speed and work efficiency, low cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

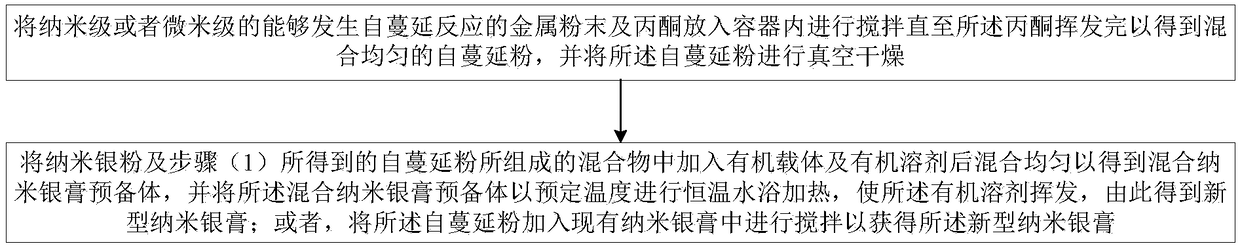

[0025] See figure 1 , The preparation method of the novel nano silver paste provided by the preferred embodiment of the present invention mainly includes the following steps:

[0026] Step 1: Put nano- or micro-scale metal powder capable of self-propagating reaction and acetone into a container and stir until the acetone is volatilized to obtain a uniformly mixed self-propagating powder, and vacuum dry the self-propagating powder.

[0027] Specifically, the self-propagating powder is an independent powder material capable of self-propagating reaction, such as two or more of Ti, Ni, Al, Zr and Nb powders, and it can also be Al / Ni, Al / Ti, Ni / Si, Ni / Ti, Al / Zr, Nb / Si and other composite self-propagating powders, one or more of them. After the self-propagating powder is triggered, a self-propagating exothermic reaction can occur. Heat can accelerate sintering. In this embodiment, the container is a beaker, and the self-propagating powder is placed in a drying box for vacuum drying fo...

Embodiment 1

[0037] The sintering method provided by the first embodiment of the present invention includes the following steps:

[0038] (1) Put high-purity Ti powder (average particle size of 50μm) and Al powder (average particle size of 40μm) into a beaker at a molar ratio of 1:3 to mix, and add an appropriate amount of acetone to the beaker and stir until After the acetone is volatilized to obtain a uniformly mixed self-propagating powder, the self-propagating powder is then put into a drying box for vacuum drying for 1.5 hours.

[0039] (2) To the mixture of nano silver powder and the self-propagating powder obtained in step (1), first add ethyl cellulose as an organic vehicle, and then drop an appropriate amount of terpineol solvent to effectively dissolve the mixture To obtain a mixed solder paste, the dissolved mixed solder paste is mechanically vibrated in a spiral oscillator for 40 minutes to fully mix the nano silver powder and the self-propagating powder, and then continue to oscill...

Embodiment 2

[0042] The sintering method provided by the second embodiment of the present invention includes the following steps:

[0043] (1) Put the nano-scale Al / Ni composite self-propagating powder into the drying box for vacuum drying for 1 hour.

[0044] (2) First, add a mixture of acrylic resin and ethyl cellulose as an organic carrier to the mixture of nano silver powder and the above Al / Ni composite self-propagating powder, and then drop an appropriate stearyl alcohol solvent, and Pre-mix to make a mixed solder paste; then, mechanically vibrate the mixed solder paste in a spiral oscillator for 30 minutes to fully mix the nano silver powder and the self-propagating powder, and then put the mixed solder paste Continue to oscillate in the ultrasonic oscillator for 70 minutes to disperse the agglomerated particles by using the air cannon generated during the ultrasonic oscillation process to make the composition of the mixed solder paste more uniform, thereby obtaining a mixed nano-silver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com