Continuous fiber-reinforced thermoplastic resin melt impregnation device and preparation method

A technology of reinforced thermoplastic and melt impregnation, which is applied in the field of continuous fiber reinforced thermoplastic resin melt impregnation device and preparation, which can solve the problems of difficult adjustment and measurement of the tension on the fiber bundle, complex shape of the impregnation device, and poor dispersion effect of the fiber bundle, etc. Thermoplastic resin melt impregnates fiber bundles, the process conditions are easy to achieve, and the effect of improving the degree of impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

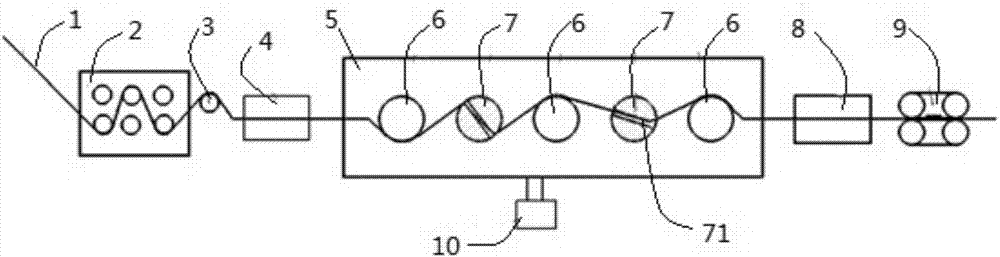

[0031] see figure 1 and figure 2 , The continuous fiber reinforced thermoplastic resin melt impregnation device provided by the present invention includes a spreading frame 2, a godet roll 3, a preheating device 4, a melt impregnation mold 5, a cooling device 8, a pulling device 9 and an extruder 10.

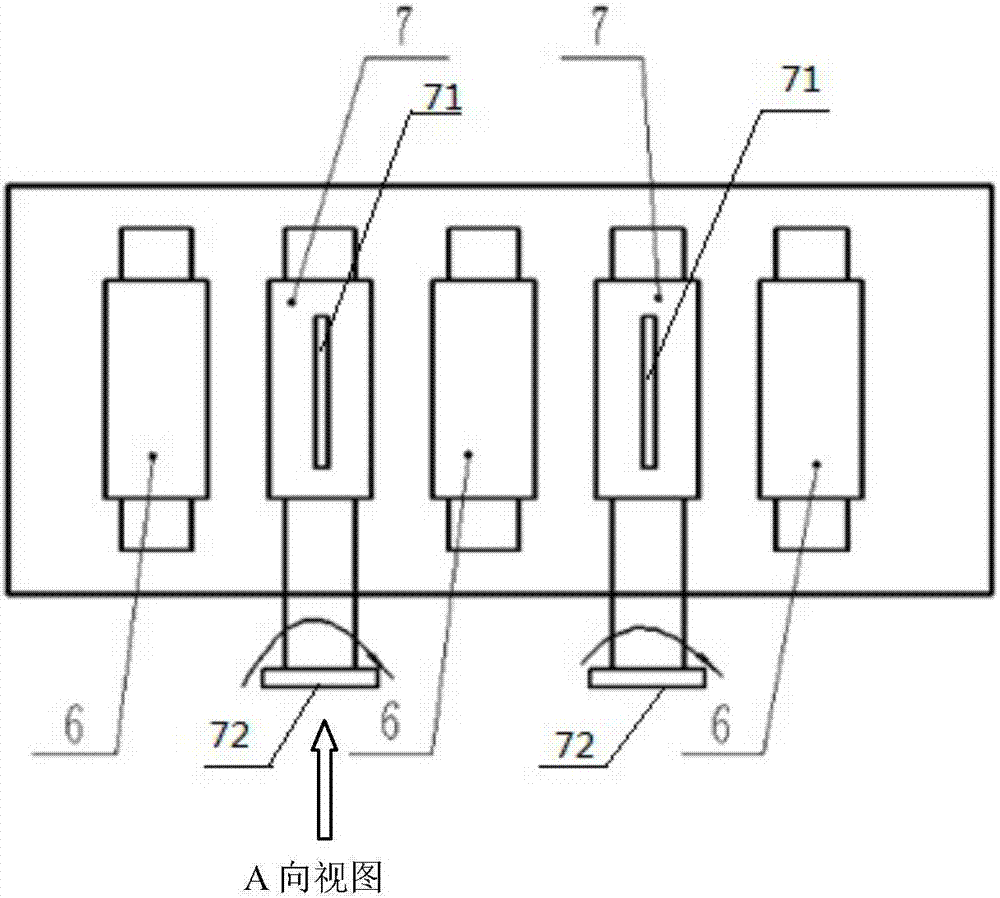

[0032] The molten impregnation mold 5 in this embodiment consists of three dispersing rolls 6 and two slit rolls 7 . The diameter of the dispersing roller 6 is 20mm and the diameter of the slit roller 7 is 20mm; the slit roller 7 has a slit 71, the slit 71 is 2mm high and 30mm long; the two ends of the slit 71 are arc transitions, and the arc The radius range is 2mm, and the slit roller 7 can rotate positively and negatively.

[0033] The dispersing rolls 6 and slit rolls 7 in the melt impregnation mold 5 are equidistant and staggered, and the center-to-center distance between adjacent dispersing rolls 6 and slit rolls 7 is 40 mm. The dispersing roller 6 in the molten impreg...

Embodiment 2

[0047] The impregnation process, impregnation method, and result evaluation method of this embodiment are all the same as in Example 1, the difference being that all slit rolls 7 are used in this embodiment, and the diameter of the slit roll 7 is 30mm. The slit 71 of the roller 7 is 5mm high and 30mm long, the two ends of the slit 71 are arc transitions, the radius of the arc is 5mm, the slit roller 7 can rotate positively and negatively; the center distance between adjacent slit rollers is 50mm . The continuous fiber bundle 10 used in this embodiment is carbon fiber, and the thermoplastic resin melt is nylon.

[0048] The heating temperature of the feeding section of the extruder 10 is 210°C, the heating temperature of the plasticizing section is 230°C, the temperature of the homogenizing section and the extruder head is 250°C, and the heating temperature of the melt impregnation mold 5 is 250°C; Dispersion and impregnation are obtained under the action of the slit roller 7;...

Embodiment 3

[0052] The impregnation process, impregnation method and result evaluation method of this embodiment are all the same as the first embodiment, the difference is that: the diameter of the dispersing roller 6 used in this embodiment is 30mm, the diameter of the slit roller 7 is 30mm, and the diameter of the slit roller is 30mm. The slit 71 of the slit roller 7 is 5mm high and 30mm long, and the two ends of the slit 71 are arc transitions, and the arc radius range is 5mm, and the slit roller 7 can rotate positively and negatively; Center distance is 50mm. The continuous fiber bundle 10 used in this embodiment is aramid fiber, and the thermoplastic resin melt is polyethylene.

[0053] The heating temperature of the feeding section of the extruder 10 is 190°C, the heating temperature of the plasticizing section is 210°C, the temperature of the homogenizing section and the extruder head is 230°C, and the heating temperature of the melt impregnation mold 5 is 230°C; Dispersion and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com