Bypass system of condensed water precision processing system of thermal power plant and control method thereof

A technology of condensate polishing and bypass system, which is applied in the field of medium-pressure condensate polishing system of conventional thermal power units, can solve the problems of inconvenient isolation and maintenance, complicated bypass device design, and the system cannot be quickly started and isolated. Overhaul and maintenance, enhance the effect of system maintenance and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

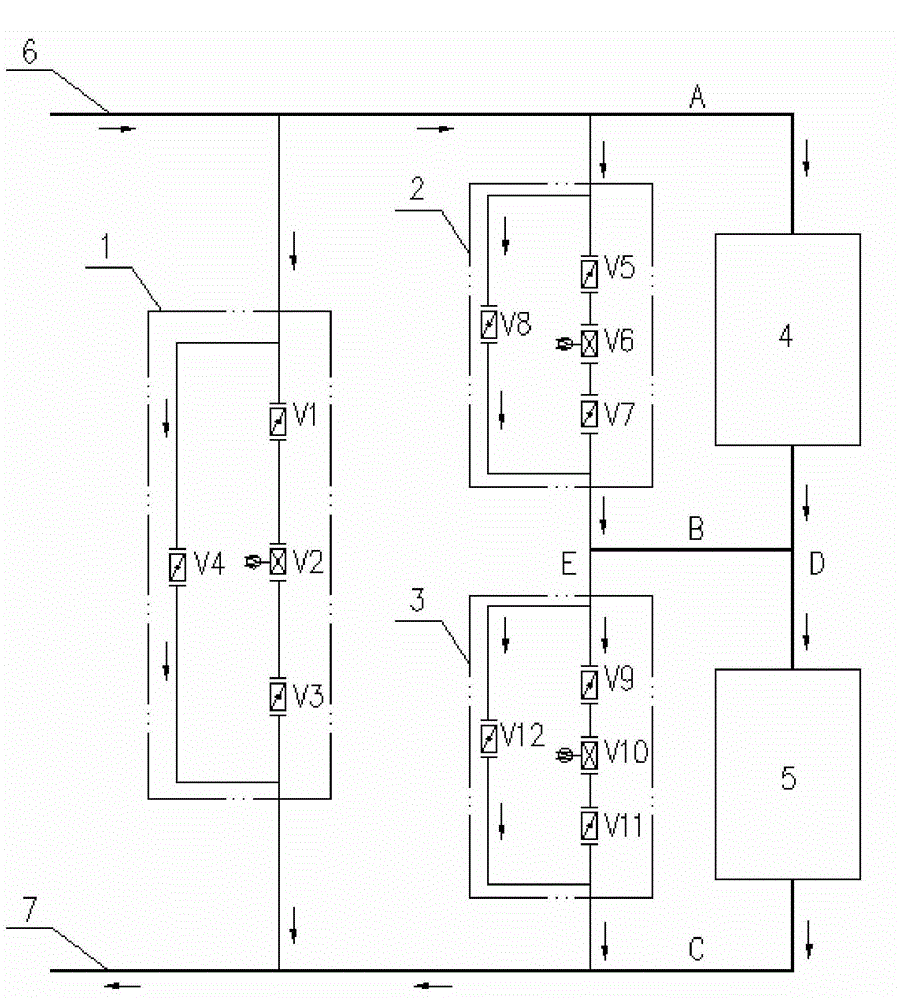

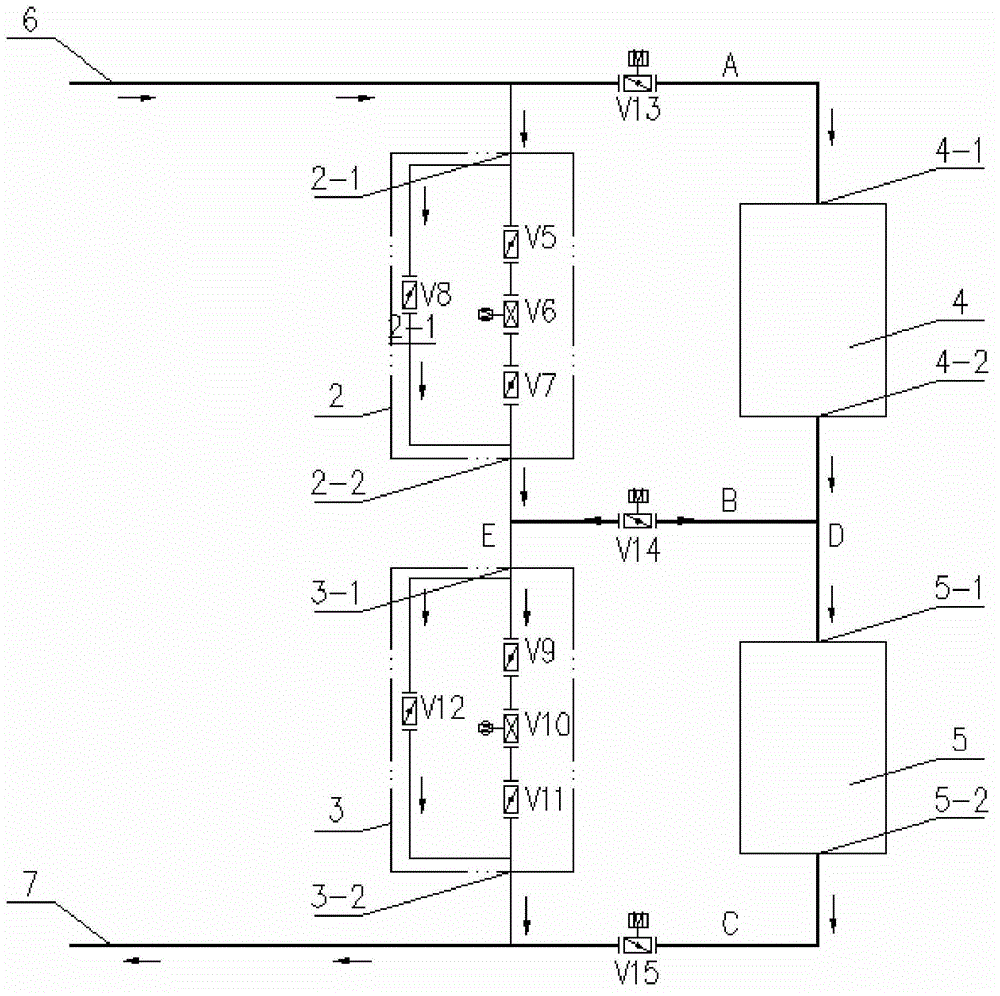

Embodiment 1

[0039] see figure 2 As shown, the embodiment of the present invention provides a bypass system for the condensate polishing system of a thermal power unit. , an intermediate pipeline D, a high-speed mixed bed unit 5, an outlet main pipeline C, and a condensate outlet 7 connected in series; the bypass system of the condensate polishing system at least includes: two-stage pre-filter unit bypass 2, two High-speed mixed bed unit bypass 3 and related pipelines, control valves, etc.; wherein, the relevant pipelines include at least branch pipeline B, bypass pipeline E, etc.; the control valves include at least bypass 2 normally open manual front valve V5, bypass 2 normally open manual rear valve V7, bypass 3 normally open manual front valve V9, bypass 3 normally open manual rear valve V11, bypass 2 automatic valve V6, bypass 3 automatic valve V10, bypass Road 2 normally closed manual valve V8, bypass 3 normally closed manual valve V12, pipeline A automatic valve V13, pipeline B au...

Embodiment 2

[0052] see figure 2 As shown, the embodiment of the present invention also provides a bypass system control method for the condensate polishing system of a thermal power unit, since the bypass system of the present invention only consists of the secondary pre-filter unit bypass 2 and the secondary pre-filter unit Bypass 3 is formed in series, and automatic pipeline valves are added, so when the working condition of the condensate polishing system is abnormal, or when the pipeline and control valve need to be isolated and overhauled, the bypass system can be used to provide a passage for the condensate, according to The control methods for different working conditions include:

[0053] Working condition 1, when the water quality of the thermal system is unqualified during the start-up stage of the unit, or the differential pressure of the inlet and outlet main pipes of the condensate polishing system or the inlet water temperature of the condensate polishing system exceeds the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com