Biological compound enzyme preparation and dark green tea making process using same for improvement of tea quality

A technology of compound enzyme preparation and biological compound enzyme, which is applied in tea treatment before extraction, biochemical equipment and methods, enzymes, etc., can solve problems such as safety hazards and inability to meet consumers' taste needs, and achieve reduction of astringency and heaping The time used for fermentation is reduced to ensure the effect of full hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

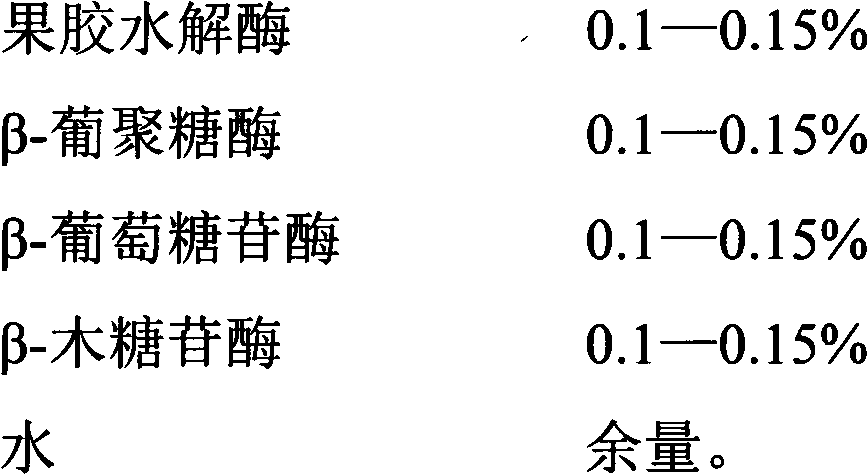

[0022] Embodiment one (production of biological complex enzyme preparation):

[0023] Add 1.2Kg each of pectin hydrolase, β-glucanase, β-glucosidase, and β-xylosidase into 1 ton of water, and stir evenly to obtain the finished biological compound enzyme preparation.

Embodiment 2

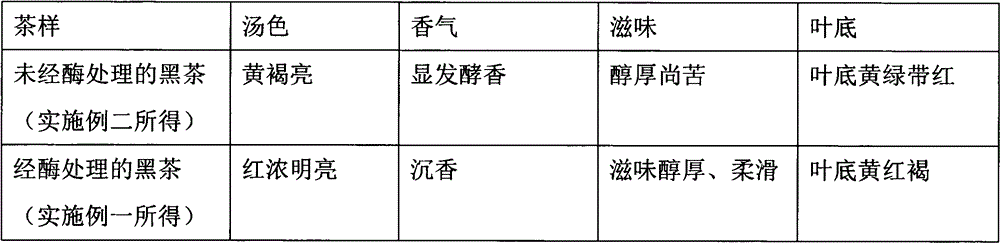

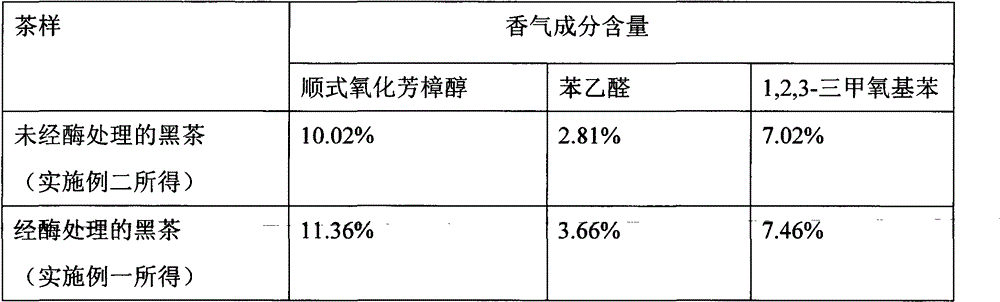

[0024] Embodiment two (black tea tea making process---do not adopt biological compound enzyme preparation):

[0025] The raw materials used are: one bud with five leaves and six leaves as the main fresh tea leaves, and the fresh tea leaves can be fresh tea leaves of different varieties and seasons.

[0026] Specific steps:

[0027] (1) Classify the fresh tea leaves to remove non-tea impurities, and then spread them under a certain temperature and humidity environment for about 15 hours;

[0028] (2) The green tea leaves treated in (1) are fixed to reduce the water content of the fresh tea leaves, the temperature of the green tea is 280° C., and the time of the green tea is 40 seconds;

[0029] (3) cooling the tea leaves after finishing to normal temperature;

[0030] (4) rolling the tealeaves processed in (3);

[0031] (5) Fermenting the tea leaves treated in (4) in piles, fermenting for 40 days under the condition of tea pile temperature of 50°C;

[0032] (6) repeatedly d...

Embodiment 3

[0034] Embodiment three (black tea tea-making process——adopt biological compound enzyme preparation):

[0035] Raw materials used: fresh tea leaves based on one bud with five leaves and six leaves. The fresh tea leaves can be fresh tea leaves of different varieties and seasons.

[0036] Specific steps:

[0037] (1) The fresh tea leaves are graded to remove non-tea impurities, and then enzymatically hydrolyzed and spread under a certain temperature and humidity environment. Spray the biological composite enzyme preparation obtained in Example 1 on the fresh leaf surface, the spraying amount is 0.25% of the fresh leaf weight, the temperature is 35° C., the humidity is about 90%, and the pH value is about 4.8. Enzymolysis and spreading are carried out simultaneously, and the time is 15 hours or so. Through long-term low-temperature, high-humidity spreading and enzymatic hydrolysis, the color of fresh leaves can be maintained, and the astringency of tea leaves can be reduced to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com