Secondary box structure of planet wheel system of speed changing box

A planetary gear train, gearbox technology, applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc., can solve the problems of life difference, increase, etc., to improve the force condition, increase the life of the auxiliary box, The effect of shortening the length of the output shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

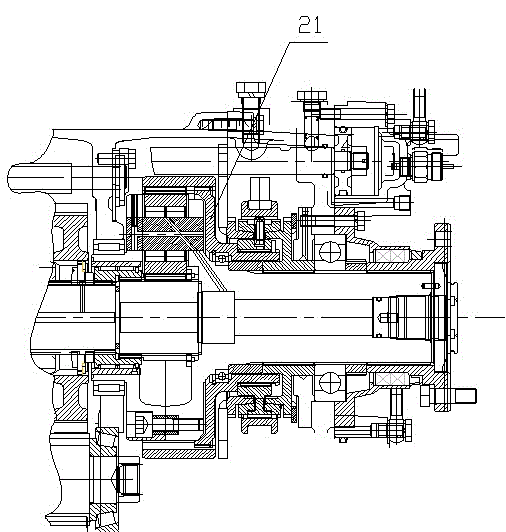

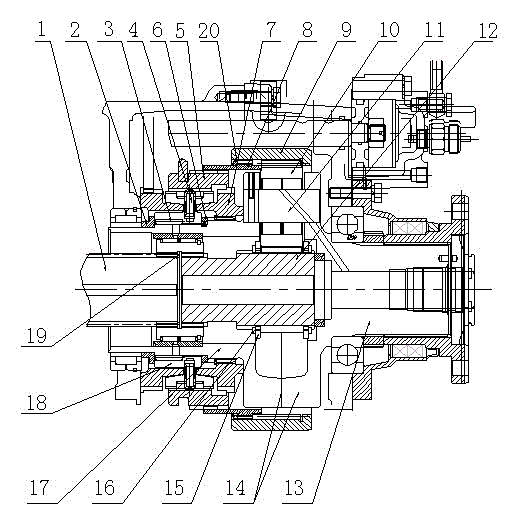

[0016] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

[0017] As shown in the attached figure, a gearbox planetary gear train auxiliary case structure, including auxiliary case planetary gear train, auxiliary case synchronizer, auxiliary case planetary gear train 11 adopts helical gears, which improves the bearing capacity of the gearbox and greatly reduces the transmission capacity of the gearbox Assembly noise; the auxiliary case synchronizer 4 is placed before the planetary gear train 11, shortening the length of the output shaft 13 of the planet carrier 14, and reducing the torsional deformation of the output shaft 13 of the planet carrier 14 in the state of high torque; canceling the traditional The ring gear bracket 21 in the structure, the synchronous gear sleeve 5 and the inner ring gear 9 are connected through the torsion spline sleeve 8; the high-grade cone hub 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com