Intelligent charging/discharging management method for coal charged into thermal power plant

A technology for coal and thermal power plants entering the factory, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of high labor intensity, disordered loading, unloading and storage work, chaotic vehicle management, etc., to reduce personnel Reduce labor intensity, avoid human interference factors, and improve the efficiency of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

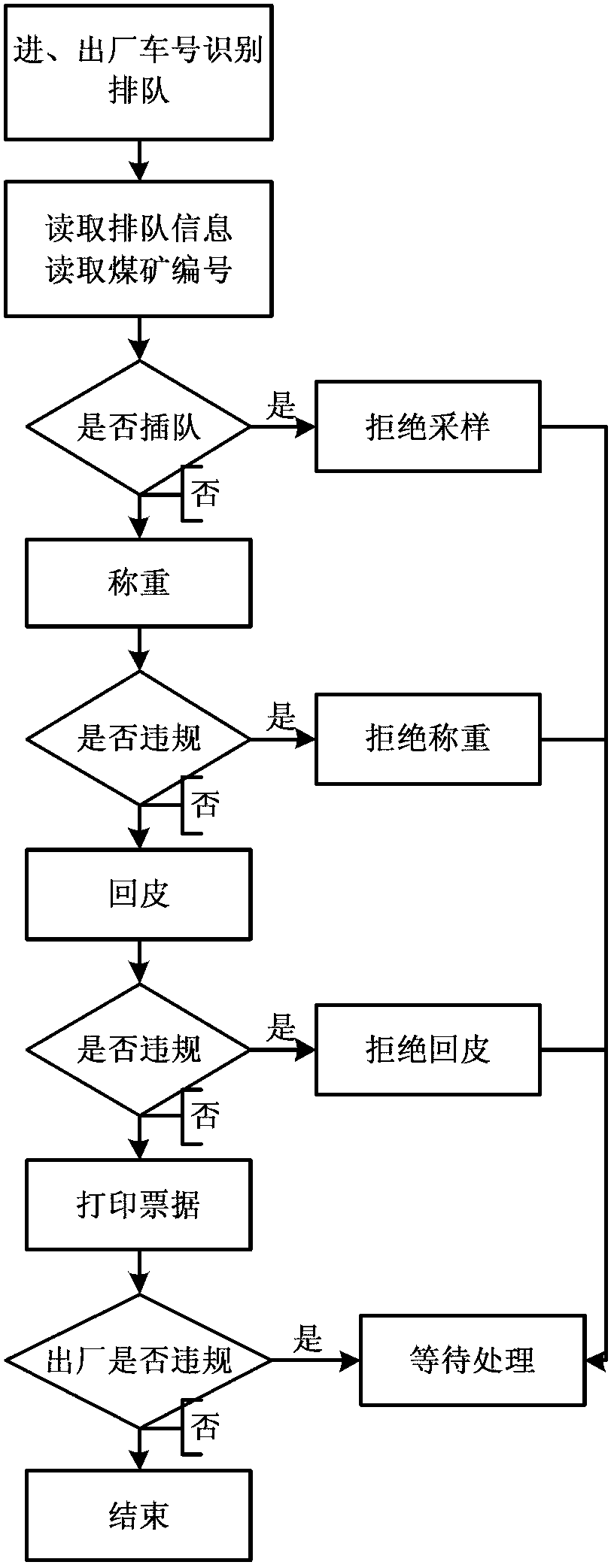

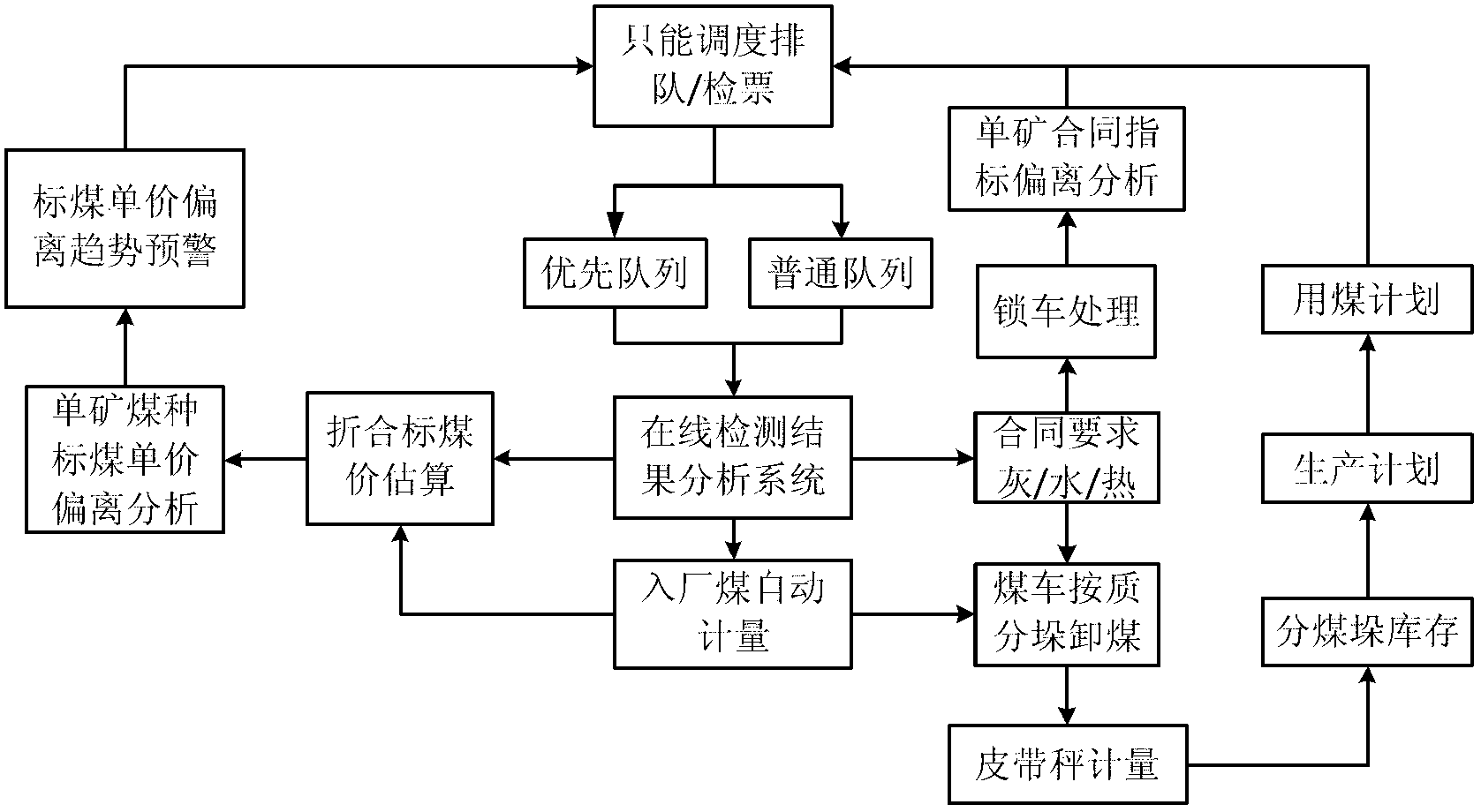

[0035] Such as Figure 1-Figure 2 , a thermal power plant incoming coal intelligent loading and unloading management method, the method includes the following steps:

[0036] Step 1: Vehicles entering the factory line up for ticket inspection;

[0037] Step 2: Scheduling;

[0038] Step 3: weighing;

[0039] Step 4: The vehicle unloads coal and deducts tons wirelessly;

[0040] Step 5: The vehicle is tamed and returned to empty;

[0041] Step 6: Generate and print the scale.

[0042] The planners can use the system software to issue purchase and dispatch plans, and perform operations such as generation, printing, and issuance of related plan cards. For plan cards that cannot be issued to drivers, they can be classified and placed in the ticket inspection room after generation. When the transport vehicle arrives, it is taken out and attached to the coal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com