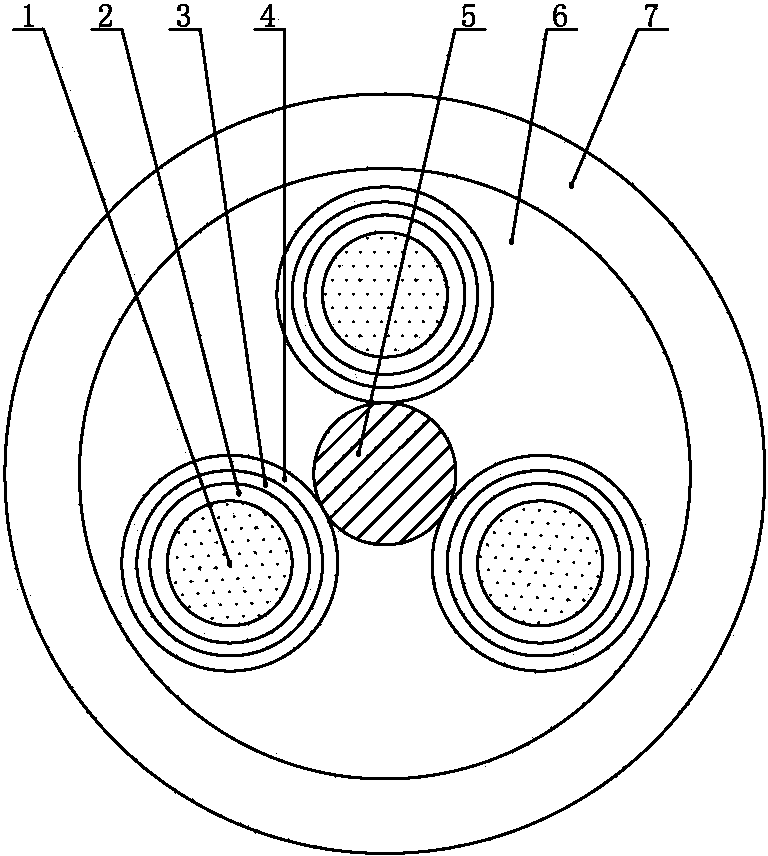

Strengthening tensile type longitudinal watertight degaussing cable for ships and warships and manufacturing method thereof

A technology for degaussing cables and manufacturing methods, which is applied in the direction of cable/conductor manufacturing, insulated cables, submarine cables, etc., can solve the problems of poor flame retardancy and poor flame retardancy of ethylene-propylene rubber, and achieve high tensile strength, The effect of ensuring the watertight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

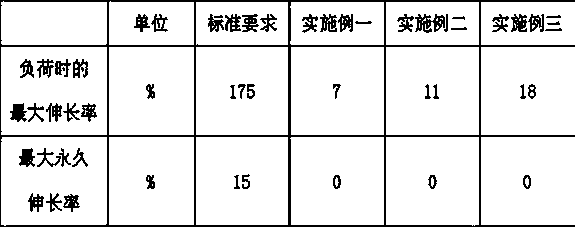

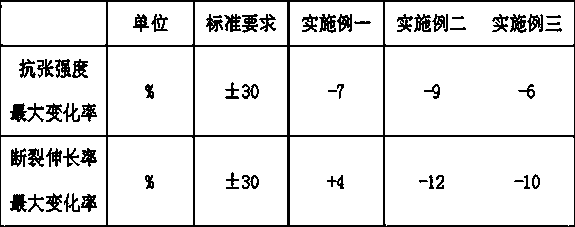

Embodiment 1

[0024] First prepare insulating rubber for use, the steps are as follows: (1) Prepare raw materials according to the following components and weight content: EPDM rubber K21: 15 parts; EPDM rubber 4045M: 5 parts; vulcanizing agent dicumyl peroxide : 0.5 parts; vulcanization accelerator triallyl isocyanurate: 0.2 parts; anti-aging agent 2-mercaptobenzimidazole: 0.7 parts; anti-aging agent 2,2,4-trimethyl-1,2 -dihydroquinoline polymer: 0.2 parts; plasticizer paraffin oil: 1.0 part; plasticizer chlorinated paraffin-52: 1 part; plasticizer microcrystalline paraffin: 0.5 part; active agent zinc oxide: 1.0 part; Active agent stearic acid: 0.3 parts; filler superfine talcum powder: 8 parts; reinforcing filler fumed silica: 1.0 parts; reinforcing filler calcined clay: 7 parts; Propylene rubber K21 and EPDM rubber 4045M raw rubber were mixed on an internal mixer at a temperature of 65°C until uniform, and then the anti-aging agent 2-mercaptobenzimidazole and anti-aging agent 2,2,4-trim...

Embodiment 2

[0030] First prepare insulating rubber for use, the steps are as follows: (1) Prepare raw materials according to the following components and weight content: EPDM rubber K21: 15 parts; EPDM rubber 4045M: 5 parts; vulcanizing agent dicumyl peroxide : 0.55 parts; vulcanization accelerator triallyl isocyanurate: 0.25 parts; antioxidant 2-mercaptobenzimidazole: 0.8 parts; antioxidant 2,2,4-trimethyl-1,2 - dihydroquinoline polymer: 0.25 parts; plasticizer paraffin oil: 1.5 parts; plasticizer chlorinated paraffin-52: 1.5 parts; plasticizer microcrystalline paraffin: 0.8 parts; active agent zinc oxide: 1.5 parts; Active agent stearic acid: 0.4 parts; filler superfine talcum powder: 9 parts; reinforcing filler fumed silica: 1.2 parts; reinforcing filler calcined clay: 8 parts; Propylene rubber K21 and EPDM 4045M raw rubber were kneaded on an internal mixer at a temperature of 70°C until uniform, and then added in turn with anti-aging agent 2-mercaptobenzimidazole and anti-aging agent ...

Embodiment 3

[0036] First prepare insulating rubber for use, the steps are as follows: (1) Prepare raw materials according to the following components and weight content: EPDM rubber K21: 15 parts; EPDM rubber 4045M: 5 parts; vulcanizing agent dicumyl peroxide : 0.6 parts; vulcanization accelerator triallyl isocyanurate: 0.3 parts; anti-aging agent 2-mercaptobenzimidazole: 0.9 parts; anti-aging agent 2,2,4-trimethyl-1,2 - dihydroquinoline polymer: 0.3 parts; plasticizer paraffin oil: 2.0 parts; plasticizer chlorinated paraffin-52: 2 parts; plasticizer microcrystalline paraffin: 1.0 parts; active agent zinc oxide: 2.0 parts; Activator stearic acid: 0.5 parts; filler superfine talcum powder: 11 parts; reinforcing filler fumed silica: 1.5 parts; reinforcing filler calcined clay: 9 parts; Propylene rubber K21 and EPDM rubber 4045M raw rubber were mixed on an internal mixer at a temperature of 75°C until uniform, and then the anti-aging agent 2-mercaptobenzimidazole and anti-aging agent 2,2,4-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com