Wind power generation device

A technology for wind power generation devices and generators, which is applied to wind power generator components, wind power generation, wind power engines, etc., and can solve problems such as difficult and reliable recycling of oil and grease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

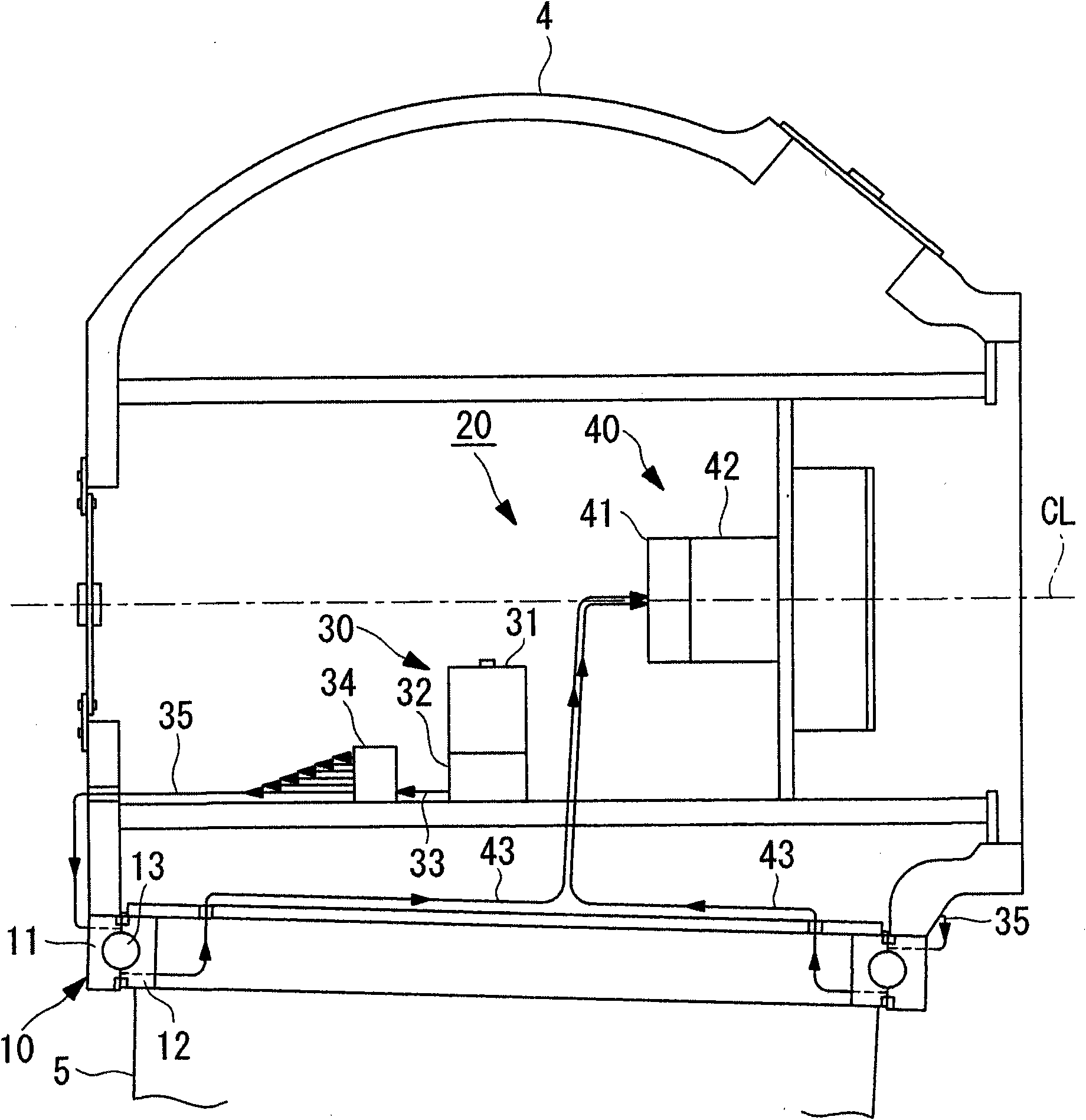

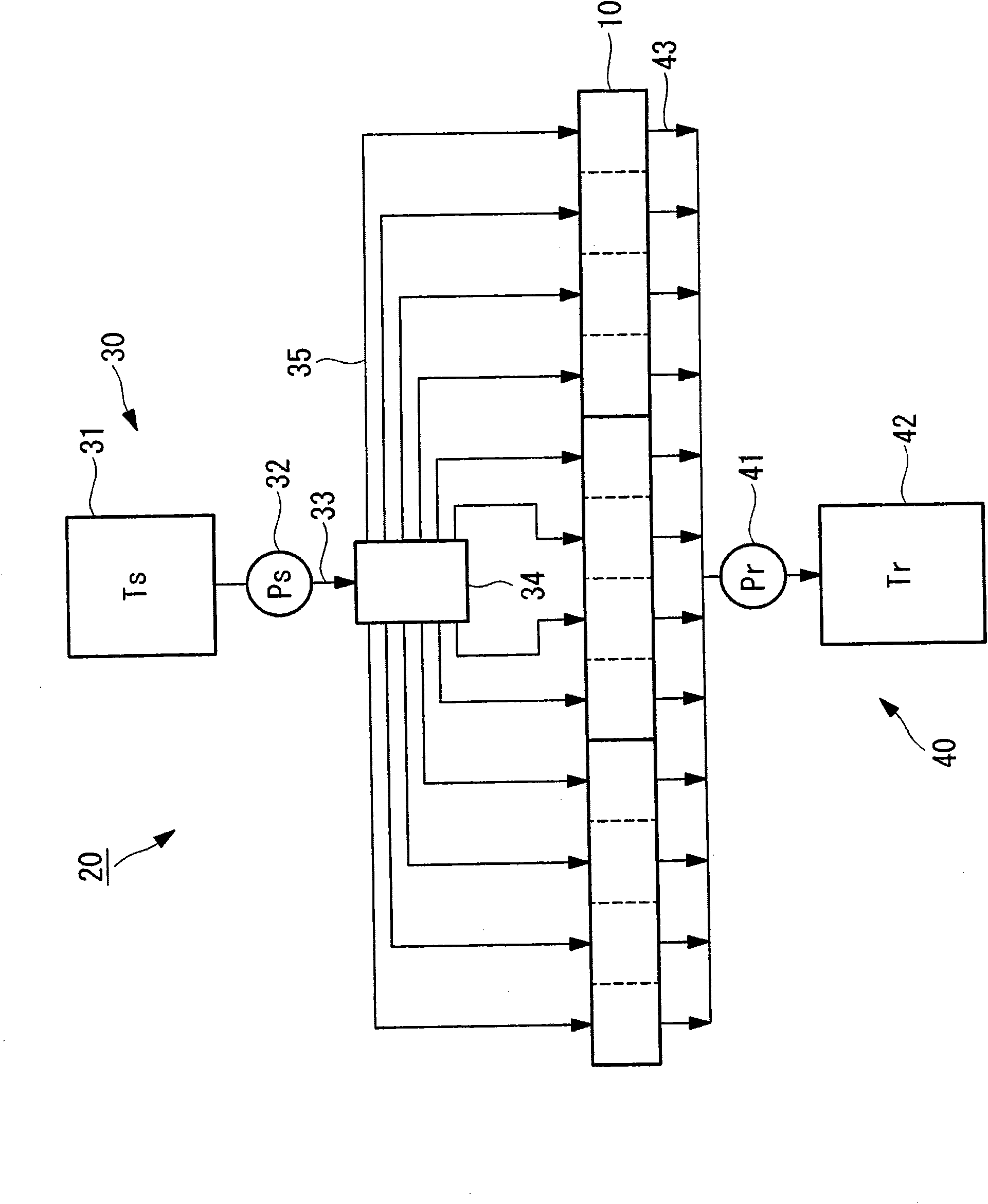

[0026] Hereinafter, an embodiment of the wind power generator according to the present invention will be described with reference to the drawings.

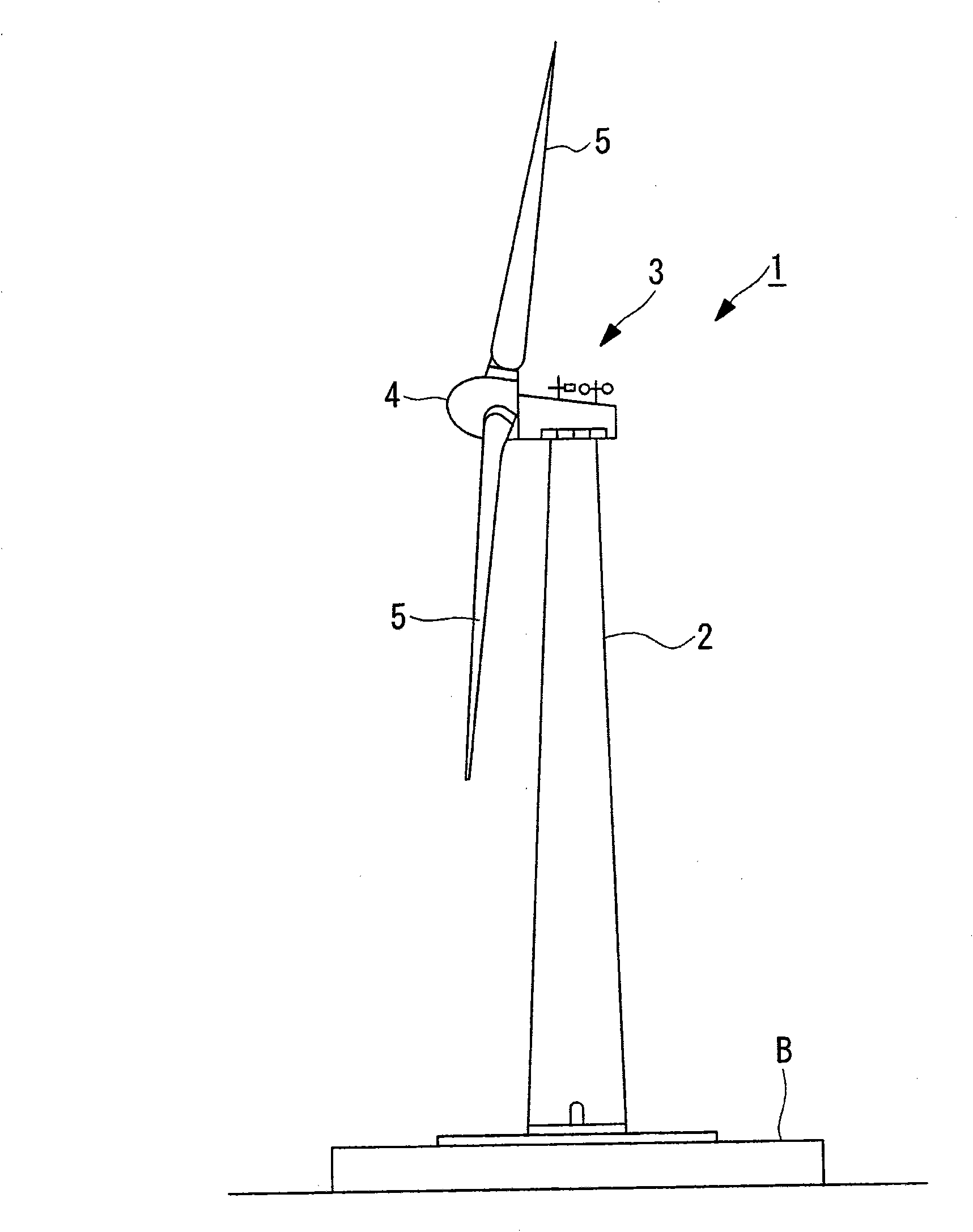

[0027] image 3 The shown wind power generation device 1 has: a windmill tower (hereinafter referred to as "tower") 2 erected on a foundation B; And the rotating head 4 is provided on the front end side of the nacelle 3 .

[0028] The rotor head 4 is mounted with a plurality of (for example three) windmill blades 5 radially around its axis of rotation. Thereby, the wind force blowing down the wind turbine blade 5 from the direction of the rotation axis of the rotor head 4 is converted into power to rotate the rotor head 4 around the rotation axis.

[0029] An anemometer for measuring a peripheral wind speed value, an anemometer for measuring a wind direction, and the like are installed at appropriate locations (for example, an upper portion) on the outer peripheral surface of the nacelle 3 .

[0030] That is, in the wind power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com