Cigarette filter tip

A filter tip and cigarette technology, applied in the field of filter tip, can solve the problems such as the inability of the mouth stick to be smoothly compounded, the high cost of cigarette manufacturing, the consumption of large paper and glue, etc., and achieve the effects of extending the distance, reducing the tar content, and softening the smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

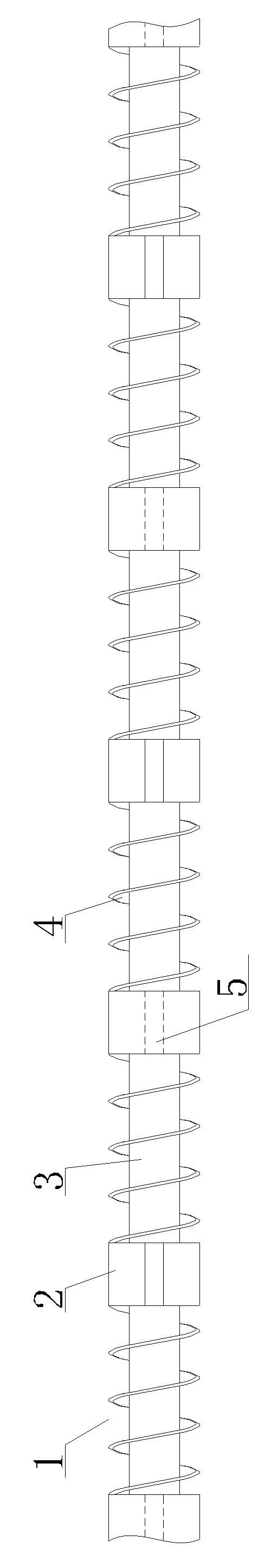

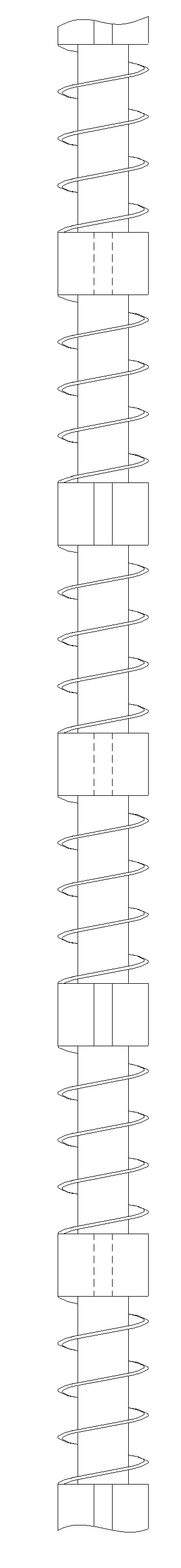

[0021] figure 1 with figure 2 It is the cigarette filter tip of the present invention. The cigarette filter includes a filter rod 1 and a packaging material coated on the outer surface of the filter rod 1, and the packaging material can be a coil paper or tipping paper, or a sleeve. The filter rod 1 includes short rods 2 arranged at intervals along the axial direction. The short rods 2 are cylindrical and have a smooth outer surface. The length of the short rods 2 is 5-10 mm. The adjacent short rods 2 are connected to each other by connecting rods 3, and the length of the connecting rods 3 is 5-50mm. A continuous threaded groove 4 is provided along the annular outer surface of the connecting rod 3 , that is, adjacent short rods 2 are connected by a threaded connecting rod. The filter rod 1 is formed by alternately connecting short rods 2 and threaded connecting rods at intervals. By arranging the short rods 2, it is possible to prevent a plurality of threaded connecting ro...

Embodiment 2

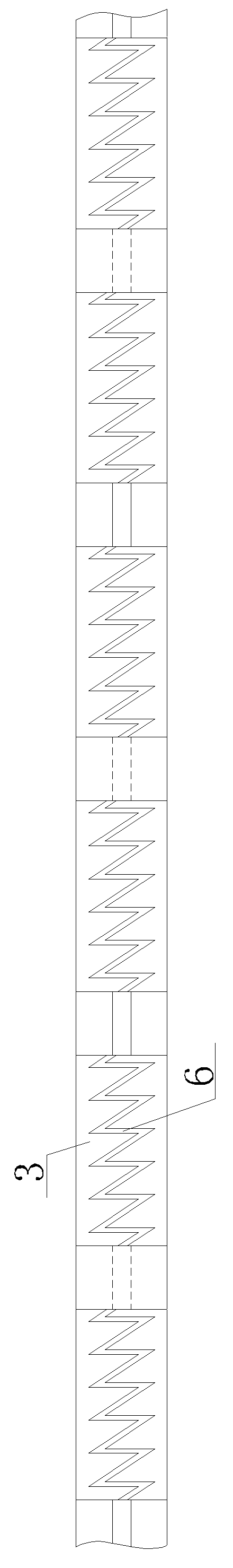

[0026] image 3 It is the cigarette filter described in Example 2. The difference from Embodiment 1 is that the groove on the outer surface of the connecting rod 3 is a "Z"-shaped continuous groove 6 arranged along the axial direction of the connecting rod 3, that is, formed by connecting Z-shaped grooves in the axial direction. At least one "Z"-shaped continuous groove 6 is provided along the axial direction of the connecting rod 3 , and when multiple "Z"-shaped continuous grooves 6 are arranged at intervals along the radial direction of the connecting rod 3 .

[0027] Others are with embodiment 1.

Embodiment 3

[0029] Figure 4 It is the cigarette filter described in Example 3. The difference from Example 1 is that the groove on the outer surface of the connecting rod 3 is an "S"-shaped continuous groove 7 arranged along the axial direction of the connecting rod 3, that is, it is formed by connecting S-shaped grooves in the axial direction. At least one "S"-shaped continuous groove 7 is provided along the axial direction of the connecting rod 3 , and when multiple "S"-shaped continuous grooves 7 are arranged at intervals along the radial direction of the connecting rod 3 .

[0030] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com