Disc mill

A pulverizer and disc technology, applied in cocoa, grain processing, food science, etc., can solve the problems of reduced pressure in the processing material chamber, low lamination crushing and shearing crushing capacity, lack of geometric constraints, etc., to achieve high pressure , the effect of increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

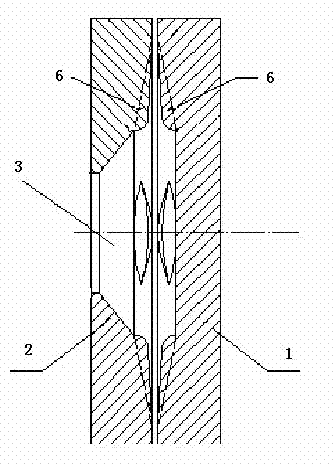

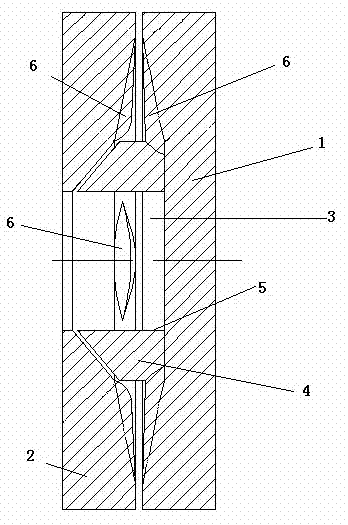

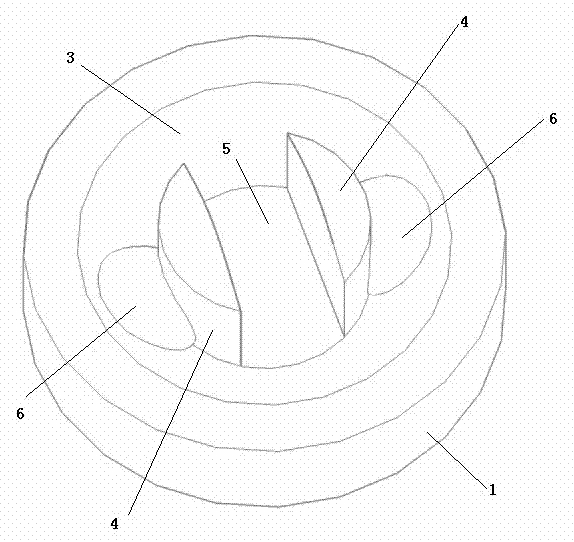

[0025] A disc pulverizer includes a movable grinding disc 1 and a fixed grinding disc 2 . Two bosses 4 are arranged on the center plane of the processing chamber 3 of the movable grinding disc 1 . There is a throwing groove 5 between the two bosses 4, and the width of the throwing groove 5 is not less than the diameter of the feeding hole of the fixed grinding disc 2. Two convex petals 6 are arranged on the outer side of the boss 4, and the convex petals 6 are symmetrically distributed on a straight line. The top curved surface of the boss 4 is a conical surface, and the outer surface is a cylindrical surface. The conical surface at the top of the boss 4 is parallel to the conical surface of the fixed grinding disc 2, and the diameter of the outer cylindrical surface is equal to the diameter of the top conical surface. The prepared material enters the processing chamber 3 through the feeding hole on the fixed grinding disc 2, and the moving grinding disc 1 rotates around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com